PCB Assembly Products

Why Choose Victory?

Our PCB Assembly Capabilities

Testing &Inspection Capabilities

PCBA Order Step

Customer Evaluation

PCBA Production Equipment

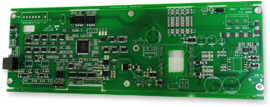

Printed Circuit Board Assembly Products

Our PCBA products cover industrial automation equipment,industrial production equipment control panels, industrial robots, automotive electronic control panels, industrial printing and coding equipment, servo control panels, CNC machine tools, medical electronics, Security electronics,consumer electronics, communication electronics, power electronics and other electronic product design categories. One-stop service for copying PCB, purchasing components, SMT production, maintenance and debugging, and quality assurance maintenance

Why choose Victory for PCB Assembly Service?

Short Delivery time

The biggest advantage of our company is the short delivery time, and the fastest delivery of SMT processing business within 24 hours after placing an order. PCBA processing standard parts can be delivered within 48 hours as soon as possible.

Fast Quotes

The company has a well-trained engineering and technical team and management team, and can provide a full set of PCBA quotations within 24 hours. For multi-material PCBA, the quotation can also be completed within 2-3 days.

Low Cost

Through centralized purchase of materials and centralized orders, centralized aggregation of materials from multiple customers, and aggregation of multiple materials of the same nature, unified orders are placed to our long-term cooperative quality assurance suppliers, and we can obtain better prices.

Extensive experience

The company has a professional team of technical engineers and rich PCBA processing experience. It strictly checks and analyzes the customer’s BOM list and related technical documents. It strictly controls the process links and conducts rigorous testing for each product

Why choose Victory for PCB Assembly Service?

Short Delivery time

The biggest advantage of our company is the short delivery time, and the fastest delivery of SMT processing business within 24 hours after placing an order. PCBA processing standard parts can be delivered within 48 hours as soon as possible.

Fast Quotes

The company has a well-trained engineering and technical team and management team, and can provide a full set of PCBA quotations within 24 hours. For multi-material PCBA, the quotation can also be completed within 2-3 days.

Low Cost

Through centralized purchase of materials and centralized orders, centralized aggregation of materials from multiple customers, and aggregation of multiple materials of the same nature, unified orders are placed to our long-term cooperative quality assurance suppliers, and we can obtain better prices.

Extensive experience

The company has a professional team of technical engineers and rich PCBA processing experience. It strictly checks and analyzes the customer’s BOM list and related technical documents. It strictly controls the process links and conducts rigorous testing for each product

Our PCB Assembly Capabilities

PCB Types and Board Shape:

PCB Types:Rigid, Flexible, and Rigid-Flex PCBs.

Board Shape: Circular, rectangular, and any opaque shape.

Size:

Minimum Size: 50 mm

Maximum Size: 700mm×460mm

Surface Finishes: Gold Plated, Lead or

Lead-free, OSP, etc.

Production Capacity:

Minimum Size: 50 mm

Maximum Size: 700mm×460mm

Surface Finishes: Gold Plated, Lead or

Lead-free, OSP, etc.

Layer Count:

We can assemble 1 to 40 layers.

(Or according to client requirements)

Lead Time:

PCB Types:Rigid, Flexible, and Rigid-Flex PCBs.

24 hours to 1 week

Testing &Inspection Capabilities

| select-content | Incoming quality control: Check whether the raw materials, such as electronic components, are the same with the BOM list provided by customer, ensure the raw materials meet the customer’s requirement. PCB board testing, solderablity testing, paste fluxtesting. |

|---|

| In-process quality control | There will be visual for each process. |

|---|

| AOI and X-ray testing | AOI is commonly used to test for defects in the inner layer prior to lamination. It includes solder amount, component location, defect and polarity, and solder joint defects. X-ray testing focuses on the fine and micro defects after lamination and can test wiring assemblies, semiconductor package, BGA solder defects, solder joint voids. |

|---|

| ICT test | ICT test is mainly used to test the welding condition of components, on-off of circuit, voltage and current value, fluctuation curve, amplitude and noise. |

|---|

| FCT test | FCT test needs IC program burning, then connect PCBA board with load, simulate user input and output, detect the function of PCBA board, find the problems in hardware and software, realize the hardware and software connection, ensure the front-end manufacture and welding normal. |

|---|

| Aging test | The aging test is to sample the PCBA board, simulate the high-frequency and long-time operation of the user, observe whether the PCBA board is invalid, judge the probability of the test failure, so as to feedback the working performance of PCBA board in electronic products. |

|---|

PCBA Order Step

Step 1 Prepare Gerber file

Step 2 Prepare BOM sheet

Step 3Send to email

Prepare Gerber file

The Gerber Files should include: All layers in the RS-274X format. Board thickness/Copper thickness/Surface finish/Stack up/Base material, etc. If you don’t provide those information, we will quote base on 1.6mm/TG130/1 oz finished copper thickness/LF HASL.

Prepare BOM sheet

The excel format should include Supplier and PN/Reference Designator/Specification/Package Type/Quantity, etc.

Prepare Gerber file

Send your all files to sales@victorypcb.com.

Customer Evaluation

William Richard(United States)

Victory provides really excellent pcb assembly service, the sales guys there are very active and passionate, and we always feel customers first place when cooperating with Victory PCB Factory.

Addy Gauzu(Spain)

I would like to express my gratitude to Shenzhen Victory PCB for their work, all orders are always completed quickly and with a proper level of feedback! It is very pleasant to work with such professionals, we will continue to order from this professional pcb assembly manufacturer!

Irene Jones(Germany)

Received the pcb boards, good packing. Thank you for Victory's professional service.The incoming inspection is accepted. The people and the product are excellent. Reliable China pcb manufacturer!

PCBA Production Equipment