Copyright © 2019-2020 ShenZhen Victory Electronic Technology Co., Ltd. 粤ICP备20070179号-1All rights reserved.Site Map Powered by iwonder.cn

Aluminum printed circuit boards are among the popular types of metal core PCBs, which are most widely used in high brightness LED products. Aluminum PCB construction of metal-based and copper-clad laminates to deliver high performance and make the circuit board an excellent electrical insulator and thermal conductor.

Aluminum PCB, also know as aluminum clad, aluminum base, MCPCB (Metal Clad Printed Circuit Board), IMS or IMPCB(Insulated Metal Substrate), Thermally conductive PCBs, etc., consists of an aluminum core with standard FR4 to create superior heat transfer to help cool components while eliminating problems associated with managing fragile ceramics.

Request Aluminum PCB Manufacturing Price

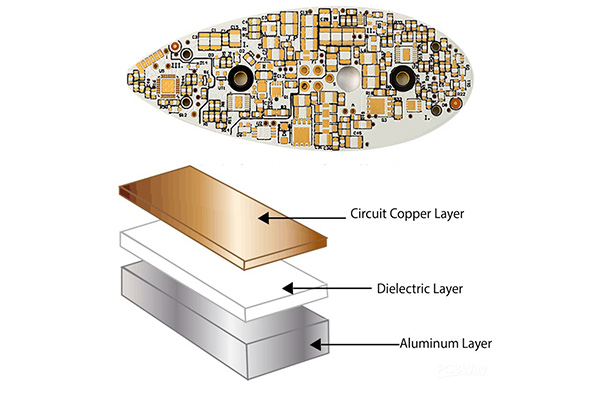

There are generally three layers in a single sided aluminum PCB, including an insulating layer, a circuit layer, and a metal base layer. For some high-end applications, double-sided variants are also designed with a circuit layer, insulation layer, aluminum base, insulation layer, and the circuit layer.

Circuit Copper Layer

The circuit layer of the aluminum circuit board consists of copper foil. These copper foils can be used in varying thicknesses from 0.5 - 5oz for PCB manufacturers.

Dielectric Layer

A dielectric layer is a thermally conductive layer and is around 50μm to 200μm thick. It had low thermal resistance and is suitable for its application.

The Base Layer

The base layer consists of an aluminum alloy substrate. The use of aluminum makes this type of PCB an excellent choice for through-hole technology.

Such aluminum circuit structures, as have been described above, are simple to design and eminently possible to manufacture at VictoryPCB. They can be easily produced using well-established manufacturing infrastructure tools, equipment, and processing techniques, which are reordered to make beneficial electronic products suitable for use in everything from consumer to high-reliability automotive, military, and aerospace products. The limits are likely to be defined more by the designer's imagination than the limits of the fundamental technology that has been described.

Higher durability

The aluminum provides mechanical durability, making it a perfect replacement for ceramic-based PCBs.

Lightweight

Aluminum is a very light metal, which is three times lighter than steel. That's why it is used in many applications such as in vehicles, keeping given the fact it decreases dead-weight and energy consumptions whilst augmenting load capacity.

Low Cost

Aluminum PCB is cost-effective as you require a smaller amount of hardware, which leads to lower assembly costs, and ultimately results in a smaller environmental footprint.

Excellent thermal conductivity and heat dissipation

Aluminum PCBs can actually transfer heat away from vital components more efficiently than a conventional rigid PCB. Regardless of whether it is single or double-sided, the aluminum backing offers an excellent thermal pathway to the environment surrounding it. It is usual for the solder mask on aluminum-backed PCBs to be black in power designs to better radiate heat.

| Capacity | 20000m²/month |

| Minimum Line Width/Gap | 0.1mm |

| Material Thickness | 0.6-5.0mm |

| Layer | 1-2L |

| Termal Conductivity | 1.0 - 8.0W/m*k |

| Material | Alumium Base, Dielectric Layer |

| Copper Thickness | 0.5 - 5oz (1oz=35um) |

| Max PCB Size | 600mm X 1200mm |

| Minimum Hole Size | 0.20mm(± 0.05mm) |

| Surface | HASL, OSP, ENIG, Immersion Silver |

Request Aluminum PCB Manufacturing Price

By continuing to use the site you agree to our privacy policy Terms and Conditions.

Recruit global agents and distributors Join us