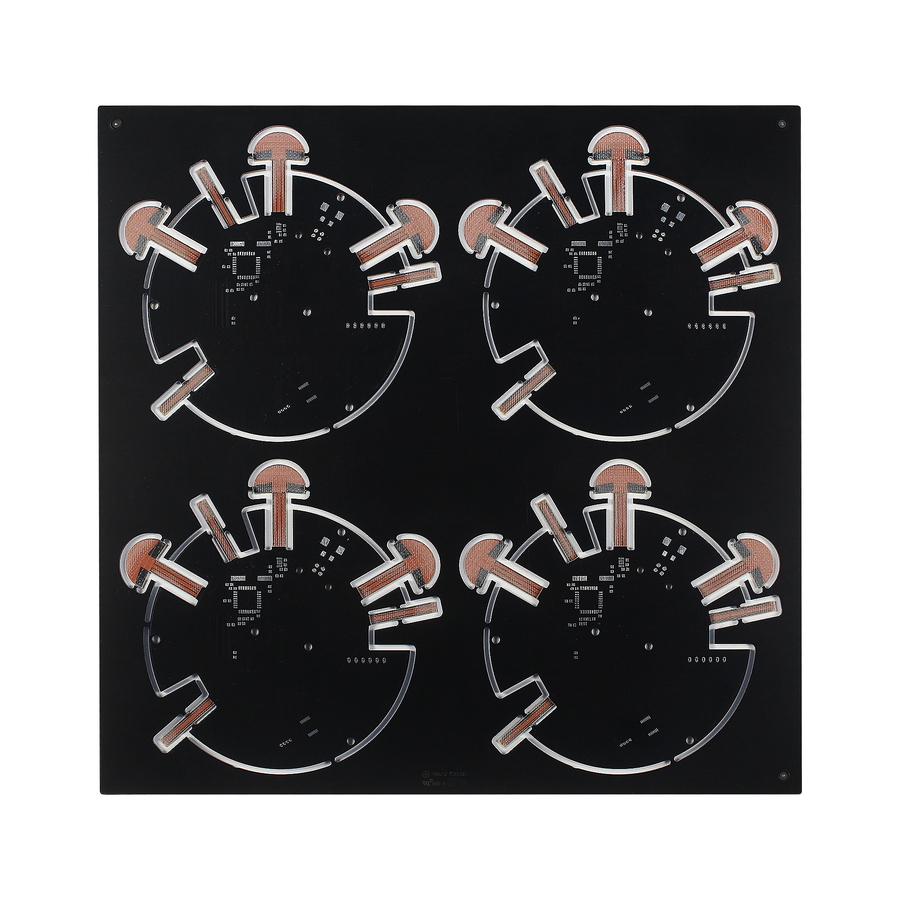

Monthly capability: 2200 Sq M/Month

Material: FR4 TG150

Dimension: 256.46mm*251.94mm

Finished board thickness: 1.55mm

Finished copper thickness: 2oz

Surface finishing: HAL

Application field: Security Devices

Monthly capability: 2200 Sq M/Month

Surface finishing: HAL

Application field: Security Devices

A Professional PCB Manufacturer since 2005

Small and Middle/Large batches, Multiple Varities, Short Lead Time

Certificated with UL (E315391), ISO 14001, IATF16949, ISO 9001, SGS, ISO13485, SA8000

Capablity 60,000Sqm/3000PNs per month, 500staffs

Make oversized board (reach to 1200mm)

Quotation will be provided within 12hours

15 years experience on PCB exporting

10% sales revenue invested in R&D and advanced automatic equipment from Japan, Taiwan and Germany every year

Product:Single Sided, Double Sided and Multilayer PCB, Rigid PCB,Flex PCB,Rigid-flex PCB,AL-base PCB.

| Material | CEM-3,FR-4(Normal to High Tg),High CTI FR-4,PolyImide(PI) ,Aluminum Base,Rogers |

| Surface finish | HAL, HASL Leadfree, ENIG, Chem Tin, OSP, Gold Finger, Immersion Silver, ENEPIG |

| Min. Core thickness | 4mil/0.1mm |

| Prepreg type | 1080, 2116, 7628, 106, 3313, 2165, 1500. |

| Max board size | 24.41X47.24inch/620X1200mm |

| Copper thickness | Min. base copper 1/3Oz |

| Max. base copper 10Oz | |

| Min. board thickness | 2- Layer 0.2mm/8mil |

| 4-Layer 0.35mm/14mil | |

| 6-layer 0.65mm/26mil | |

| 8-Layer 1.0mm/40mil | |

| 10-Layer 1.3mm/51mil | |

| 12-Layer 1.6mm/63mil | |

| 14-Layer 1.8mm/71mil | |

| 16-Layer 2.0mm/79mil | |

| AOI (Automatic Optical Inspection) | Max.table size: 685X685mm |

| Max.inspect size: 620X620mm | |

| Max. thickness: 3.20mm(126mil) | |

| Min. thickness: 0.10mm(4mil)-core | |

| Min. width/gap: 3mil/3mil | |

| Board thickness Tolerance | ±0.10mm(4/6layers) |

| ±0.13mm(8/10layers) | |

| ±0.15mm(12/14/16layers) | |

| Max.board thickness | 6.0mm/236mil |

| Min.line width/space | 3/3mil |

| Min hole size | 4mil/0.1mm |

| PTH wall thickness | ≧25µm |

| Max. aspect ratio | 12:01 |

| PTH dia. Tolerance | ±0.075mm/3mil(Standard), ±0.05mm/2mil(Advanced) |

| NPTH dia. Tolerance | ±0.05mm/2mil(On laminate area) |

| ±0.03mm(On ground area) | |

| Hole location Tolerance | ±0.075(Standard) ±0.05mm(Advanced) |

| ±0.13(2nd drilled hole to 1st drilled hole location (mm) | |

| Slot size tolerance | ±0.075mm(board thickness≤1.0mm) |

| ±0.10mm (board thickness>1.00mm) | |

| V-CUT Remain thickness tolerance | ±0.10mm(Standard), ±0.076mm(Advanced) |

| Peelable mask Thickness | ≥8mil(0.2mm) |

| Insulation Resistance | >1012Ω |

| Through hole Resistance | <300Ω |

| Current breakdown | 10A |

| Peel Strength | 1.4N/mm |

| S/M Abrasion | >6H |

| Thermal stress | 288℃ 20Sec |

| Test Voltage | 20-300V |

| Min.blind/burried via | 4mil/0.1mm |

| Impedance control | (50Ω-100Ω)±10%(Standard)、(50Ω-100Ω)±7%(Advanced) |

We have 55 QC, FQC, QA specialists who utilize 100 testing devices, advanced techniques like IMDS and PPAP. Our products are tested in physics lab strictly before shipment on every part number. And report will be included in carton. All of our pcbs are RoHs/Reach/CE compliant.

Staffs in Quality department get traning once per week to be skilled and professional.

1. FedEx/DHL/UPS/TNT for samples, Door-to-Door;

2. By Air or by Sea for batch goods, for FCL; Airport/ Port receiving;

3. Delivery Time: 3-10 days for samples; 8-15 days for batch goods.

1. Solid

2. Professional

3. No broken during the shipment

Please call us on +86136 6225 0684, or mail us at sales@victorypcb.com

By continuing to use the site you agree to our privacy policy Terms and Conditions.

Recruit global agents and distributors Join us