Printed circuit boards (PCBs) have been an integral part of electronics for many years. Through the years, electronic devices are getting smaller and more complex and so are the PCBs needed to connect the components in an efficient manner. As robotics and electronic design begin to be taught as early as grade school, the art of PCB layout becomes more meaningful. What follows are 5 common myths about PCB layout:

1. Once an electrical schematic is complete, the hard work is over.

The layout of a PCB from an electrical schematic seems like a simple two-step process: Place the required components and connect the wires/traces to the appropriate point on the components. However, many factors still must be considered when getting from the schematic to a finished PCB design suitable for prototype or production. Some of these include physical design constraints (size and placement of the parts, orientation of parts on opposite side of PCB), electrical interaction between signals, heat dissipation, and signal loss through the wires/traces. All of these and more still require an engineering mind to accomplish a working design.

2. PCB layout for prototyping and production are similar.

Depending on the intent of your design, you may make vastly different choices in the types of components to be used. For a prototype or proof-of-concept design, you may opt for through-hole parts for as many parts as you can. They're relatively inexpensive and easy to solder to your PCB.

However, in a production design, you want to shy away from use of through-hole parts in favor of surface-mount parts. Through-hole parts are costly to assemble in volume and can dramatically increase production cost due to increased board size, layer count, component availability delays, etc. Also, reducing the number of unique parts on the bill of materials (BOM) is another way to minimize production cost.

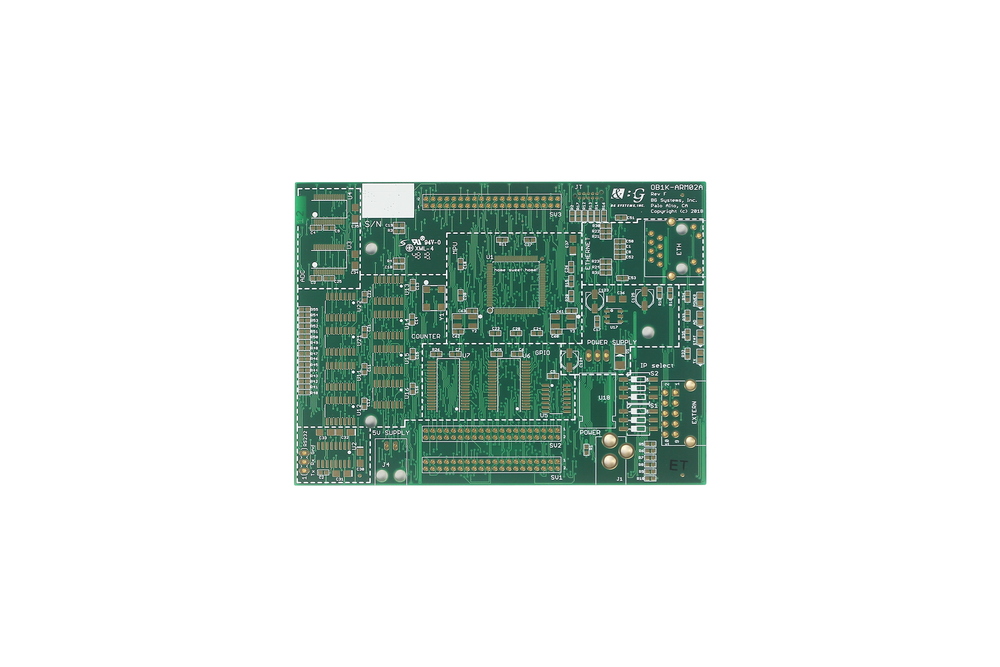

3. Components can be placed almost anywhere on the board, and it will result in an effective PCB.

Planning your PCB layout in terms of modules, similar to your schematic, is a much more effective way to layout your design. Components close in proximity in the schematic should also be in close proximity in the layout. Most designers like to think of the design in terms of modules. One common error in layout is to ignore the physical height of a component and its location with respect to case or neighboring boards.

4. Power distribution is not a critical element in layout.

Power delivery is critical in the performance of any circuit. Some parts require much more power, and better conditioned power, than others. This has to be taken into account early in the design or circuit performance will suffer.

Supplying power to all of the various components on a PCB can be done in several ways. But, regardless of the method, it needs to be planned so as to deliver the correct current to each component without creating voltage drops by unnecessarily running power in series, creating longer paths, or choking down the current with trace size or a chopped-up power plane (a plane with poorly placed through vias that will limit the current flow).

5. Standard DRC settings are applicable for all designs.

The best strategy to getting the PCB when you want and how you want, at a cost that doesn't kill your project, is to know your PCB manufacturer and tailor your “in tool” design-rule-check (DRC) settings to their manufacturing “sweetspot, whenever possible.” Working with a trusted manufacturing partner (and to their strengths) maximizes the success rate of the PCB design. Just because you can design it, doesn't mean every PCB manufacturer can build it.

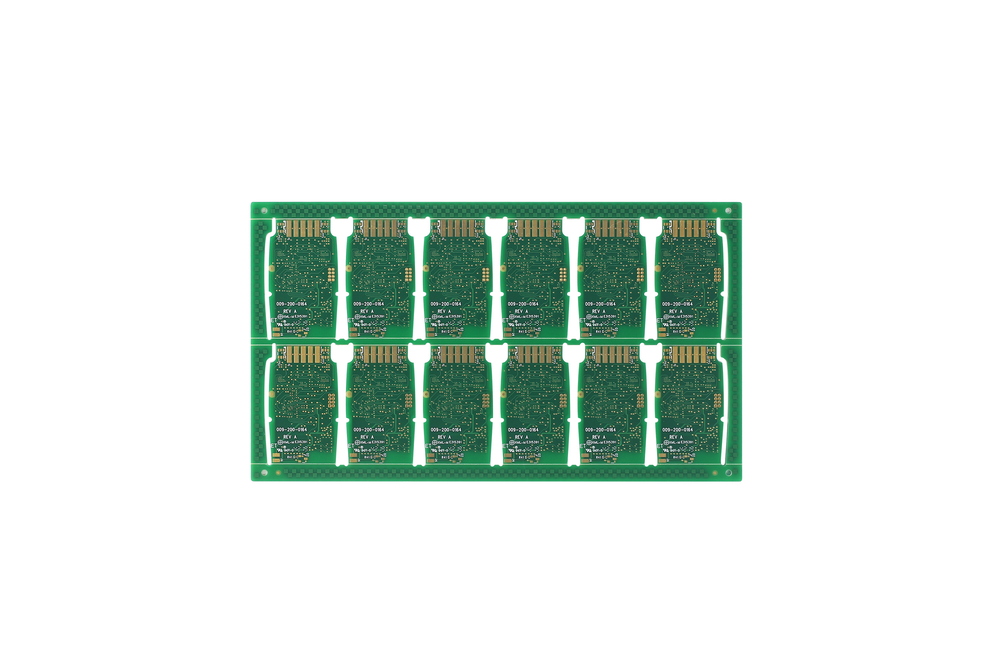

About us

Victory is a professional PCB manufacturer which established in 2005. Adhere to be a specialized manufacturer for multiply species, small to medium series, and quick turn production, we insist to provide 3H(high quality, high precision and high density) PCBs for our customers. If you are looking for a reliable merchandise of PCB Fabrication, please contact us now!

By continuing to use the site you agree to our privacy policy Terms and Conditions.

Recruit global agents and distributors Join us