Over the years, different forms and types of printed circuit boards (PCB) are being developed by PCB manufacturers to suit the needs of their teeming customers.

And for the PCB coil boards, coil PCB suppliers are working tooth and nail to ensure that these classes of PCB products are made available to buyers at the best time.

However, due to the design and unique nature of the coil PCB, coil PCB suppliers are always facing a tough time producing this special electrical component.

For this reason, it then becomes very important that when buying coil PCB, you do so from a trusted and professional coil PCB supplier that can provide you the best product for your hard-earned money.

In this article, we shall be considering the important things and components that separate the coil PCB from other forms of PCB.

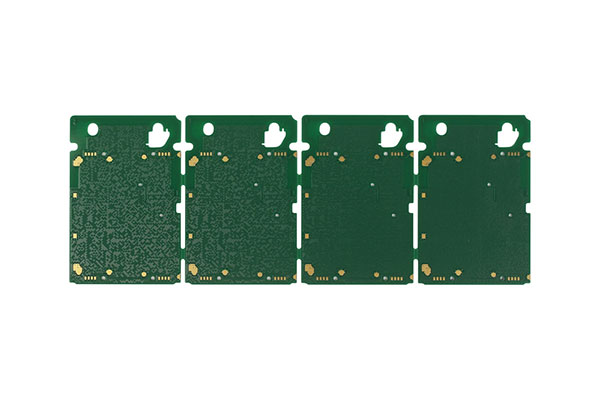

Coil PCBs

Coil PCB is also called a spiral coil board, or RF coil. The coil PCB is mostly used to describe the design of PCB whereby a single print coils all over itself, usually in a round or spiral form.

To save money and space, the coil PCB has been widely used in onboard planar inductors in place of any other physical inductor component.

By doing this, coil PCB has several advantages such as high accuracy, simple structure, measurement, better linearity, and many other benefits.

In time past, the method used for the manufacture of coil PCB was widely used for IR received.

However, the technique gained a vast level of popularity when coil PCB suppliers decided to use many coils over a multi-layer PCB, all in an attempt to produce a minute PCB motor.

Frankly speaking, going through all that the coil PCBs requires is very time consuming and difficult to do.

Module PCBs

If you have ever heard of or come across the program modules or modularity, then you will have a better understanding of the module PCBs

Just like you may already know, these set of module boards are units put together to accomplish a single function.

So, whenever these modules are manufactured into individual boards, they will automatically become module printed circuit boards (PCBs).

In most cases, power boards and display boards can be transformed into module boards.

In appliances such as the air conditioners, both the DA/AD modules, clock module, and other forms of modules exist.

With these different modules present, they can easily be transformed into smaller boards that can be plugged into the major control board and used for various applications.

In doing this, when there is a similar power module with different specs of A/C, then the same type of power board can easily be put to use without necessarily redesigning the board. This, you can tell, will also reduce costs drastically.

Overall, the coil PCB is generally known to be smaller in size, very portable, lightweight with a coil that can be opened with little or no opening effort, and also providing a wide range of frequency.

Contact us for High-Quality Coil PCB.

We have a global reputation as the one-stop coil PCB supplier and the manufacturer of other superior PCB products.

Do you need high-quality PCB products? Kindly click here to see our range of products. We will be exceedingly glad to do business with you.

By continuing to use the site you agree to our privacy policy Terms and Conditions.

Recruit global agents and distributors Join us