The base material is an important part of the PCB, which will greatly affect the electrical performance, mechanical performance and reliability of the electronic assembly, so it must be carefully selected.

Generally, base materials for PCB boards can be divided into two categories: rigid materials and flexible materials. The most common of rigid substrate materials is copper clad laminates. Copper clad laminate is a product made of wood pulp paper or fiberglass cloth as a reinforcing material, impregnated with resin, covered with copper foil on one or both sides, and hot pressed. When it is used in the production of PCB multi-layer boards, it is also called core board (CORE). At present, the copper clad laminates available on the market, considering the base material, can be mainly divided into the following categories: paper laminate, composite laminate, and fiberglass cloth laminate.

Because this kind of PCB laminate is composed of pulp and wood pulp, it is sometimes called cardboard, V0 board, flame-retardant board and 94HB, etc. Its main material is wood pulp fiber paper, which is pressurized and synthesized by phenolic resin. PCB board.

This kind of paper laminate is not fireproof, can be punched, and has low cost, low price and low relative density. We often see phenolic paper laminate such as XPC, FR-1, FR-2, FE-3, etc. And 94V0 belongs to flame-retardant paperboard, which is fireproof.

The wood pulp fiber paper or cotton pulp fiber paper is used as the reinforcing material, and glass fiber cloth is used as the surface reinforcing material at the same time. The two materials are made of flame-retardant epoxy resin. There are single-sided half-glass fiber 22F, CEM-1 and double-sided half-glass fiber board CEM-3, among which CEM-1 and CEM-3 are the most common composite base copper clad laminates.

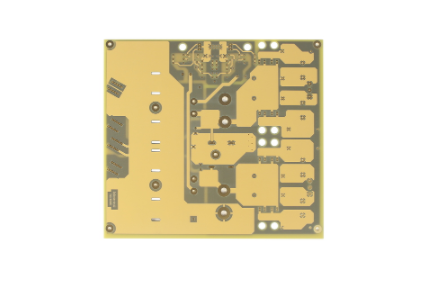

Sometimes called epoxy board, glass fiber board, FR4, fiber board, etc., it uses epoxy resin as adhesive and glass fiber cloth as reinforcing material. This kind of circuit board has a high working temperature and is not affected by the environment. This kind of board is often used in double-sided PCB, but the price is more expensive than the composite PCB substrate, and the common thickness is 1.6MM. This kind of substrate is suitable for various power supply boards, high-level circuit boards, and is widely used in computers, peripheral equipment, and communication equipment.

Victory PCB can provide CEM-1, CEM-3, FR4, FR4 Halogen Free, Rogers, Aluminum, Polyimide. High Tg, High CTI >600v, please feel free to contact us if you have any needs.

By continuing to use the site you agree to our privacy policy Terms and Conditions.

Recruit global agents and distributors Join us