Choosing a PCB manufacturer can be a daunting undertaking since there are numerous considerations to consider. Consider the following factors when selecting a PCB manufacturer:

The quality of printed circuit boards (PCBs) is a crucial consideration. Consider manufacturers with a history of creating high-quality PCBs and certifications such as ISO 9001.

Consider the lead time that each manufacturer needs to produce your PCBs. If you need your PCBs urgently, find a manufacturer to meet your delivery deadline.

Location: Consider the manufacturer's location. Choosing a local manufacturer can facilitate faster communication and delivery, particularly for smaller orders.

By considering these considerations, you may select a PCB manufacturer capable of producing high-quality PCBs that fit your particular requirements.

From time to time, I receive questions regarding the choice of PCB contract manufacturing:

· where to order the manufacture of a printed circuit board;

· how to choose the right manufacturer for your projects;

· what to pay attention to;

· what is the difference between one or another contract manufacturing of printed circuit boards;

· Which contract manufacturers of printed circuit boards will make the board cheaper / faster / better?

Right away - there is no single universal solution. This question requires an individual approach. Based on what your ultimate goals are. Is the goal of the project the maximum saving of resources and funds?

This could be a complex high-tech device or an amateur development (prototyping board). Meanwhile, the methodology for choosing a suitable PCB manufacturer remains unchanged.

To begin with, it is worth understanding one crucial thing.

The definition of requirements for purchased printed circuit boards used for the manufacture of electronic devices is made by customers.

That is us.

And we end up choosing one PCB manufacturer or another. Is the selected manufacturer the most suitable?! This question will remain open until we learn how to choose PCB manufacturers.

How to do this and why you can't stop at the first one that comes across - read below.

The supplier's evaluation is carried out to determine the degree of compliance with its requirements. A supplier is considered eligible if it can supply printed circuit boards or electronic assemblies:

1. the required quality;

2. to the required time;

3. at an acceptable price.

Meet in clothes. And acquaintance with printed circuit board manufacturers (suppliers) should be started by visiting their website.

Collecting as much information as possible about a possible future partner is beneficial at this stage. You can start by looking at the supplier's website. It is hardly worth trusting a supplier who does not have it.

If the PCB manufacturer has a website that looks high quality and inspires confidence, we move on.

Find out:

· how long ago was it created

· whether the supplier has its production;

· check the supplier as a counterparty through the official website of the tax service.

You can call from the contacts section and expand your acquaintance to a telephone conversation. It can be useful for further fruitful cooperation with a printed circuit board manufacturer or supplier. Try to get more information.

You can make printed circuit boards yourself - at home, or you can - by choosing a professional manufacturer and supplier.

Having entrusted the manufacture of printed circuit boards, it is imperative to keep your finger on the pulse, especially when it comes to electronic components (printed circuit boards with mounting).

List essential criteria and report periodically to rate the PCB supplier/manufacturer. For example, given the following criteria:

· product quality;

· fare;

· price level;

· the efficiency of deliveries;

· ease of interaction.

According to this criterion, the assessment is carried out on the basis of information on the quality of products received during the analyzed period of time. This question can be unambiguously answered only if there was already some experience of cooperation.

This criterion makes it possible to assess the availability of PCB courier delivery services based on the options/options of transport logistics companies.

For example, the supplier organizes delivery by a courier company at his own expense, or with payment by the recipient.

The criterion allows for expertly assessing the financial affordability of printed circuit board manufacturing services. The basis for this is the analysis of the average price level for a group of printed circuit boards from a given supplier.

One of the factors affecting the price level is the status of the PCB supplier. A printed circuit board supplier can be a manufacturer with its production or act as an intermediary.

The assessment is carried out by comparing the actual delivery times of printed circuit boards with the declared ones:

· the supplier delivers products in accordance with the stated deadlines;

· discrepancies between the actual and declared terms are insignificant;

· deviations from the stated deadlines exceed the allowable value,

Also, attention should be paid to the systematic violation of delivery dates. This will allow us to form a more objective assessment of the printed circuit board manufacturer according to this criterion.

Ease of interaction with contract manufacturing plays an essential role in manufacturing printed circuit boards. In this case, the positive factors will be:

· lack of language barriers;

· availability of personal managers;

· competence of employees;

· PCB supplier loyalty.

First, compare the resulting overall ratings of suppliers/manufacturers (degree of compliance with your requirements).

Second, process the additional information you've gathered about the supplier.

This will allow you to choose the PCB manufacturer that best suits your needs.

A trial batch can be ordered to evaluate the technical competence of a printed circuit board manufacturer. An objective assessment of the results of this work will make it possible to decide finally. In particular, conclude the compliance of the supplier with your requirements. And as a result, the possibility of placing future orders for printed circuit boards in the company in question.

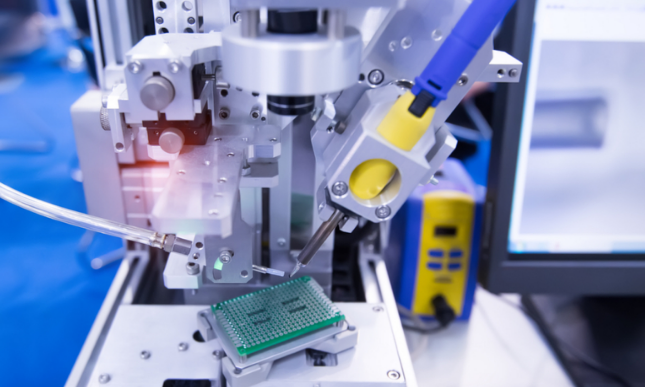

· Does the enterprise have the necessary technological equipment and infrastructure for the manufacture of printed circuit boards (electronic components);

· Is there a plan for implementing a Quality Management System (QMS) in electronics contract manufacturing?

· availability of valid certificates;

· Quality Policy and Objectives;

· loading of production capacities;

· The largest customers.

In conclusion, I recommend specific manufacturers of printed circuit boards.

These are proven organizations with which I had to deal. And the experience of cooperation with which I can share.

This is the first PCB manufacturer worth mentioning.

We have our production of simple printed circuit boards. The products of this supplier are characterized by:

· relatively low prices (concerning domestic competitors);

· high speed of production and delivery of two-layer printed circuit boards.

Cons

· lack of personal managers (to resolve some issues, you have to wait a long time to connect with the right specialist);

· staff turnover.

Suppose you solve the issue of fast production of printed circuit boards at relatively affordable prices. In that case, it is unlikely that among domestic manufacturers, you can find someone more suitable for this request.

These suppliers do not have their production of printed circuit boards. However, they work on a selection system directly with manufacturers.

· own production facilities for mounting components on printed circuit boards,

· an extensive database on the production and manufacture of printed circuit boards and electronic components

· the staff of personal managers and highly qualified technical specialists.

Varied manufacturers may have varied capabilities; therefore, selecting a manufacturer that can match your individual requirements is essential. Consider the size, complexity, and amount of the PCBs you require, and ensure that the manufacturer you select has the necessary equipment and skills to construct them.

The cost of the PCBs is also a significant aspect to consider. Compare bids from many manufacturers, but don't simply choose the lowest price. Consider each manufacturer's quality, capabilities, and customer service as well.

A good PCB manufacturer should be responsive, communicative, and willing to work with you to ensure you have the required PCBs. Consider manufacturers that provide excellent customer service and support.

By continuing to use the site you agree to our privacy policy Terms and Conditions.

Recruit global agents and distributors Join us