The evolution of soldering technologies in the electronics industry has been marked by a pivotal shift from traditional lead-based solders to environmentally-conscious lead-free alternatives. For years, lead-based soldering, primarily using Tin-Lead alloys, was the industry standard, appreciated for its affordability and excellent physical properties. However, increasing awareness of the environmental and health hazards associated with lead has led to stringent regulations, prompting the exploration and adoption of lead-free soldering solutions.

This article delves into the critical comparison between lead and lead-free soldering for Printed Circuit Boards, dissecting their physical, chemical, environmental, and functional characteristics. From melting points to wettability, tin whisker formation, costs, environmental impact, and longevity, we explore how the choice between these soldering methods can significantly influence electronic manufacturing.

Lead-based solder refers to a type of solder alloy that contains lead as one of its primary components. The most common formulation of lead-based solder is the Tin-Lead (Sn-Pb) alloy, with the ratio of tin to lead typically being around 60:40. This specific ratio is often referred to as the eutectic composition, where the alloy has a distinct melting point, allowing it to transition directly from a solid to a liquid state and vice versa.

Lead-based solder has been historically used extensively in various industries, particularly in electronics manufacturing, for its favorable properties such as a relatively low melting point (around 183°C or 361°F), ease of use, and cost-effectiveness. It has been a popular choice for creating solder joints on Printed Circuit Boards (PCBs) to connect electronic components like resistors, capacitors, and integrated circuits.

However, the use of lead-based solder has declined over the years due to growing concerns about the environmental and health hazards associated with lead exposure. As a result, there has been a global shift towards adopting lead-free solder alternatives in compliance with regulations aimed at reducing the impact of hazardous substances in electronic products.

Lead-free solder refers to a type of solder alloy that does not contain lead as one of its main components. The shift towards lead-free soldering has been driven by environmental and health concerns associated with the use of lead-based solders. Various lead-free solder alloys have been developed as alternatives to traditional Tin-Lead (Sn-Pb) solder, aiming to maintain the performance and reliability of solder joints while eliminating the toxic effects of lead. The melting point of lead-free solder may range from 50 to 200 °C or higher. Adequate wetting ability in lead-free solder calls for approximately 2% flux by mass.

Several lead-free solder alloys are available, and manufacturers may choose the one that best suits their specific requirements. Some common lead-free solder alloys include:

Tin-Bismuth (Sn-Bi): This alloy has a lower melting point compared to other lead-free alternatives, making it suitable for applications where lower soldering temperatures are desirable.

Tin-Silver (Sn-Ag): This alloy, without copper, is another popular lead-free choice. It provides good thermal fatigue resistance and is widely used in electronics manufacturing.

Tin-Zinc (Sn-Zn): This alloy is used in some lead-free solder formulations, offering an alternative without the use of silver or copper.

Lead-free soldering has become a standard practice in many industries, especially in electronic manufacturing, to comply with environmental regulations such as the Restriction of Hazardous Substances Directive (RoHS).

Lead solder and lead-free solder are two types of solder alloys used in various industries, particularly in electronic manufacturing for applications such as printed circuit board (PCB) assembly. Here's a comparison between lead solder and lead-free solder.

Lead solder (e.g., Sn-Pb) with a 183°C melting point contrasts with lead-free solders (e.g., Sn-Ag-Cu) ranging from 217-227°C. Lead-free solder addresses environmental concerns but poses challenges like higher melting points. The industry's shift reflects a balance between environmental responsibility and technical considerations. Lead-free solders are harder to work with due to their elevated melting points, diverging significantly from the lower 83°C/361°F melting point of lead alloys.

| Soldering compound | Melting temperature | |

| Lead-based Pb-37Sn solder | 183°C | 361.4F |

| Lead-free Sn-3.5Ag solder | 221°C | 429.8F |

| Lead-free Sn-58Bi solder | 139°C | 282.2F |

| Lead-free Sn-0.7Cu solder | 227°C | 440.6F |

| Lead-free Sn-8.8Zn solder | 198°C | 388.4F |

| Lead-free Sn-3.4Ag-4.8Bi solder | 205°C | 401F |

| Lead-free Sn-3.8Ag-0.7Cu solder | 217°C | 422.6F |

| Lead-free Sn-8Zn-3Bi solder | 197°C | 386.6F |

Click here to check out the effect of different concentrations of elements on the melting point of the solder alloy.

In terms of physical features, leaded solder is softer than lead-free solder, potentially impacting contact resistance. Despite its high melting point, lead-free solder experiences fewer modifications and thermal effects, making it reliable for SMD assembling over time. However, lead-free solder appears less shiny and smoother than leaded solder, and its lower wettability raises concerns about joint reliability. Balancing these factors is crucial when choosing between leaded and lead-free solder for specific applications.

| Parameters | Leaded Solder | Lead-free Solder | Units |

|---|---|---|---|

| Electrical Conductivity | 11.5 | 15.6 | IACS |

| Thermal Conductivity | 50 | 73 | (W / m) * 1 k * 1 s |

| Melting Point | 183 | 218 | °C |

| Resistivity | 15 | 11 | M ohm-cm |

| Surface Tension | 481 | 548 | mN/m |

| Fatigue Life | 3 | 1 | |

| TCE | 23.9 | 21.4 | micrometers/M/°C |

| Density | 8.5 | 7.44 | g/cm3 |

| Shear Strength | 23 | 27 | MPa |

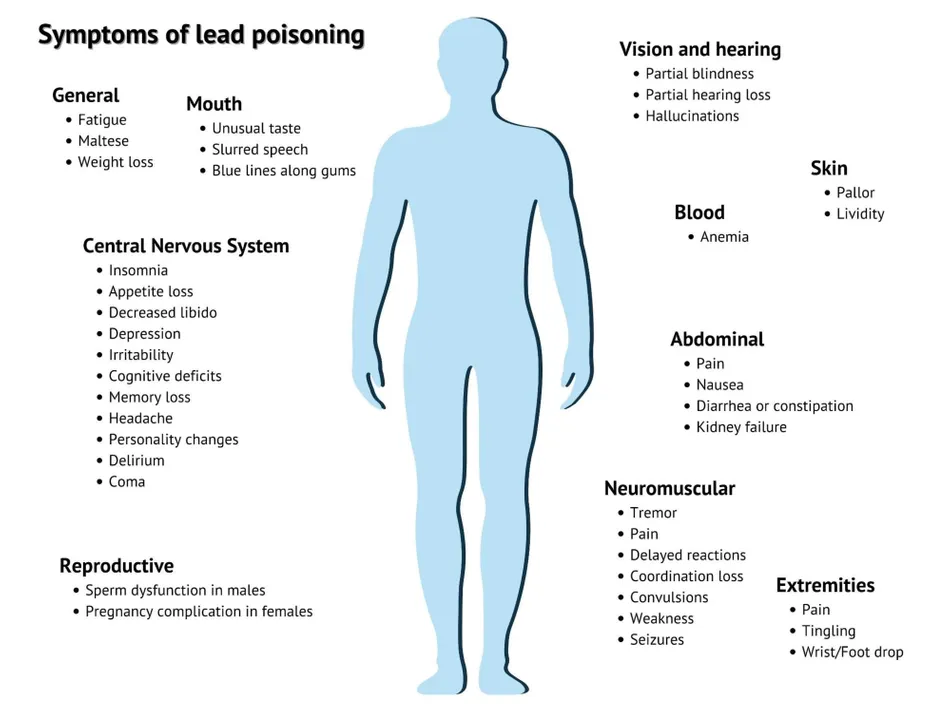

The toxicity of lead is a major concern, as it bioaccumulates and releases harmful substances during soldering, leading to respiratory issues, eye irritation, and potential carcinogenic effects. Safety precautions, such as wearing masks and avoiding ingestion during lead soldering, are crucial. The EU's directives, WEEE and RoHS, enforced since the early 2000s, ban lead in electronics manufacturing globally. Lead-free soldering is increasingly adopted by environmentally-conscious companies, recognizing lead's health risks, especially for vulnerable populations. Despite lead elimination in some industries, solder remains a source of exposure, emphasizing the importance of health precautions for workers in lead-emitting industries.

The picture below lists out some symptoms of lead poisoning in humans.

Lead solder joints, known for robust intermetallic compounds, may offer better resistance to thermal cycling. In contrast, lead-free solder joints, with more susceptibility to cracking, are influenced by higher processing temperatures. Factors affecting longevity include temperature cycling, mechanical stress, and operating environment. Ongoing advancements in lead-free solder aim to improve reliability, narrowing the gap with lead solder. The choice depends on application requirements, environmental concerns, and the balance between performance and sustainability.

Lead, at approximately $2 per kg, is significantly cheaper than Tin (around $30 per kg) and Silver (over $750 per kg). Lead's lower cost contributes to more economical lead-based solder production, impacting the overall alloy price as lead percentage increases.

Lead solder, with its cost-effectiveness and established production processes, contrasts lead-free solder, incorporating pricier elements and facing higher material costs and production complexity. Market dynamics, regulatory compliance, and long-term environmental and health considerations contribute to the cost difference. Raw material costs play a pivotal role in shaping business policies, directly influencing PCB and product profitability.

While lead solder may be monetarily cheaper, lead-free solder aligns with environmental and health regulations, driving its increased adoption. The choice hinges on specific application needs, weighing cost efficiency, sustainability, and regulatory compliance. From a manufacturing perspective, leaded solder is considered more cost-efficient due to its lower material costs, especially when compared to the pricier components in lead-free solder, making it a reasonable choice with quality.

For manufacturers operating in countries with restrictions on leaded electronics, the use of lead-free solders becomes mandatory. In contrast, hobbyists may opt for lead-based solders in small-scale applications due to their ease of use and cost-effectiveness.

However, for commercial usage, lead-free solders are considered a sensible choice, aligning with environmental regulations and health considerations. Despite the advantages of lead-based solders, their toxic nature poses challenges in justifying their usage. The decision to choose a particular solder type should consider factors such as health, environmental safety, costs, design requirements, and other relevant considerations. Balancing these factors ensures a responsible and informed choice in selecting the appropriate solder for a given application.

The choice between leaded and lead-free solder paste can impact final product quality, but meticulous control of soldering parameters by PCB manufacturers can mitigate these effects. The design layout of the circuit board and appropriate component selection play crucial roles in overcoming quality control issues.

The decision to use lead-free products for processes like wave soldering or through-hole soldering is based on specific design parameters and the product-use demands of the assembled PCBs. The higher temperatures associated with lead-free soldering necessitate careful board layout and component selection to prevent metal decomposition or damage to sensitive electronic components, especially during reflow processes with prolonged exposure to high temperatures.

PCB manufacturers should assist with RoHS material compliance, aligning with global lead restrictions.

In conclusion, soldering is a crucial process in electronics, offering two types: lead solder and lead-free solder. Despite leaded solder's advantages in melting point, wettability, cost, and appearance, environmental and health concerns have made lead-free solder the enforced choice. Lead-free solder, though safer, presents challenges like a higher melting point and lower wettability, impacting reliability. The right solder choice depends on project specifics, emphasizing the need to understand the properties and differences between leaded and lead-free solder for optimal decision-making.

Connect with us at VictoryPCB by sales@victorypcb.com, and let's discuss the best soldering solutions tailored for your needs. Your decision matters in building a sustainable and efficient electronic future. Act now for smarter, safer, and more reliable soldering solutions. Your success is just a connection away!

By continuing to use the site you agree to our privacy policy Terms and Conditions.

Recruit global agents and distributors Join us