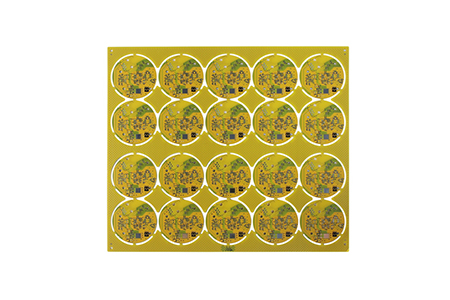

The printed circuit boards (PCB) are one of the components used to build many electronic devices for some years now. So, most of the engineers involved in the manufacturing of these electrical circuit boards are conversant with the different materials used.

In the building of PCBs, one important material used is FR-4. To get a quality one, you need to partner with a reliable and trusted FR-4 PCB manufacturer.

FR-4 simply means flame retardant grade 4. It is a glass fiber-fortified adhesive sheet that provides architectural stability to the materials. The epoxy resin components of the FR-4 confer on its strength and make it flame- resistant. This makes FR-4 printed circuit boards well-liked among manufacturers.

Beneficial Features of FR-4 Materials

Apart from the flame-resistant properties highlighted above, we have other benefits that favored its popularity are given as follows:

1. FR-4 is an affordable material

2. It has a better electrical insulation feature due to its high dielectric strength

3. It is lightweight due to its high-value strength-to-weight ratio.

4. FR-4 is water-resistant and this makes it suited for water PCB applications.

5. It is thermal resistant

6. It is yellow to light green which makes it suitable for different applications.

Tips on how to choose the right FR-4 materials for your PCB.

When building an FR-4 PCB, the thickness of the materials used is very essential to its performance. The thickness is measured in millimeters or inches.

The factors that must be considered when choosing FR4 substances for your PCB are as follows:

1. Select a thin FR-4 material for making PCB with limitation in space. This material assists fragile components needed to build tools such as USB connectors, Bluetooth extras, etc. They are also suitable for space-efficient design.

2. Thin FR-4 material is also suitable for building PCBs that required adjustability. For example, thin material is good for medical and automotive PCBs which need regular adjustments.

3. To build a PCB with a groove design, a thin FR-4 should be avoided as this could lead to high chances of board wreckage.

4. The thickness of the FR-4 material can affect the weight of PCB and this might also influence the compatibility of the components.

The implication is that a thin FR-4 material will make the weight of the board light. Lightweight boards are shipped with ease and are very enticing.

There are conditions for using FR-4 material. If the applications demand any of the following, then FR-4 materials are not suitable.

1. Optimum temperature resistance: If a PCB is built to be used in a high-temperature environment, FR4 is not suitable. An example of such PCB is the one designed for aerospace applications.

2. Lead-free soldering: A low-temperature FR-4 material cannot be used for a RoHS- compliant PCB. This is because the use of lead-free soldering can bring about an increase in temperature to around 250 degrees Celsius.

3. Supersonic frequency: FR-4 materials cannot be used for PCB that is exposed to high-frequency signals. It will affect the unity of the system.

In need of high-quality FR-4 PCB?

FR-4 PCBs are a very important component of electronic devices. Their quality cannot be compromised as a result of its function in the device hence it is advisable to source a high-quality one from a reliable and trusted FR-4PCB manufacturer.

ShenZhen Victory Electronic Technology Co., Ltd is a world-renowned industry for quality FR-4 PCB production. We have a team of skillful and high-tech professionals that can transform superior quality materials for designing a high-quality product. Kindly contact us for our lists of products and make your order today!

By continuing to use the site you agree to our privacy policy Terms and Conditions.

Recruit global agents and distributors Join us