PCB, which simply means Printed circuit board lays a good foundation in modern electronics technology. Its indispensability is seen in its applications for the development of various electronic products. One of such products commonly used nowadays is LED PCB.

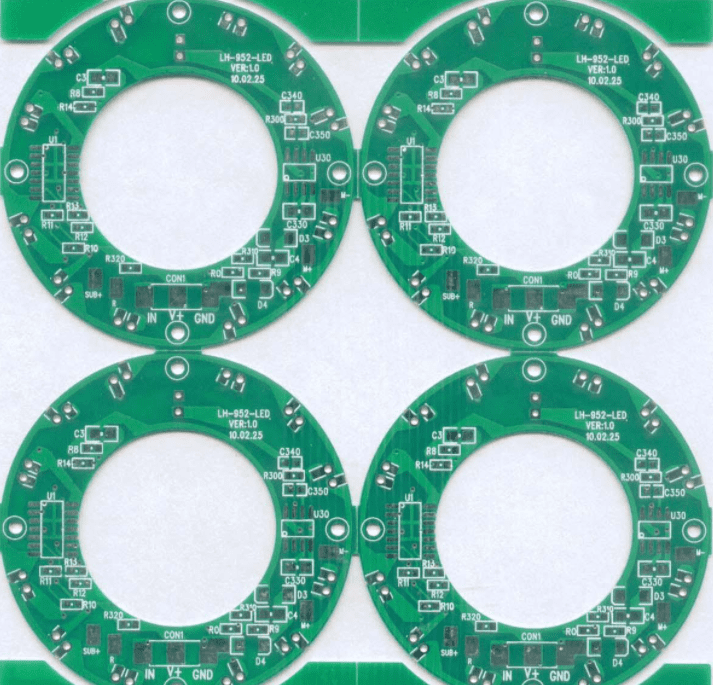

This light emitting diode printed circuit board (LED PCB) is specifically designed such that the PCB is used as a base board for LED lightning. In PCB LED, the LED is soldered to the PCB and lights up when electricity is passed through the circuit board.

Usually, many LEDs are soldered to the PCB to generate multiple lights. However, the passage of electric current to light up these LEDs generate a lot of heat.

Therefore, there is usually a need for a thermal heat sink which is to remove the heat. Another alternative is that the material of the PCB may be designed with a high conducting metal core such as Aluminum, which is a great conductor and can easily get rid of the heat generated.

The aluminum PCB is enriched with a thin layer of a dielectric material which enhances thermal conductivity. The dielectric material improves the efficiency of heat transfer and thus helps in the overall cooling of the LED PCB.

Nowadays, we no longer need to be afraid of darkness like Thomas Edison. With the help of Light emitting diode, it is now quite easy to generate light. In addition, LED lightning is durable and environmentally friendly.

Let's look at some of the benefits of LED lightning over traditional incandescent methods of lightning:Less power consumption: The consumption of energy by LED lights with high quality is six to seven times less than that of traditional incandescent light.

This means that LED lights offer you a higher efficiency with lower energy relative to the traditional lights. Replacing your traditional incandescent lights by LED light can reduce the energy consumed in your home by over 80 percent.

Longevity: LED lights have longer life spans relative to incandescent lights. They can run for as long as 25,000 hours, which is a huge three years of continuous use! With this, LED lights not only saves your time and effort but also saves your money. With LED lights, you don't need to keep wasting your money to install new light bulbs all the time.

More Efficient: The efficiency of a device is a measure of the fraction of the total energy which is used by the device to perform a useful work. Traditional incandescent light bulbs have lower efficiency such that about 90 percent of the total energy is wasted in form of heat.

However, with LED lights, this is reduced significantly. Thus, using LED lights mean harnessing more of the energy you paid for to perform useful work, while using traditional incandescent light wastes the energy as heat.

Highly Compact: The small size of LED Lights make them very compact. Therefore, they can be used in various applications ranging from electronic devices such as computers and smart phones to traffic lights and automobiles on the streets.

Mercury Free: LED lights are more environmentally friendly because they contain no Mercury. This offers an advantage over the traditional incandescent light bulbs which contain mercury that can cause environmenal pollution and poisoning to plants and animals in their natural habitats. With this, the disposal of LED lights have no negative impact on the environment.

PCB LED lights are used in various lightning applications. They are cost effective, energy efficient and well compact. Here is a list of some of the common applications of PCB LED lights

Automobiles: Indicators, brake lights and headlights of cars and other vehicles can make use of PCB LED lights. Aluminum PCB LED lights are specifically used in these automobiles because of its durability, efficiency in heat dissipation as well as affordable costs.

Computer: aluminum PCB LEDs are also used in computers where there is a particular need to efficiently get rid of heat due to the sensitivity of Computer hardware components to heat. Certain hardware components such as CPU boards and power packs also make use of aluminum PCBs for quick dissipation of heat generated.

Medical use: During surgical operations and medical checkups in hospitals, high-powered LED lights are used. These LED lights make use of aluminum printed circuit boards because of its long life span and the ability to dissipate heat rapidly. This is to ensure that the lightning is stable during a surgery. In addition to lightning for surgery, various scanning technology also make use of aluminum PCBs.

Are you in need of a professional manufacturer and supplier of LED PCB? If yes, then you can count on us for the best deal at a pocket-friendly price.

Kindly click here to reach us for more information or to place and order.

By continuing to use the site you agree to our privacy policy Terms and Conditions.

Recruit global agents and distributors Join us