Affordable and durable lighting sources are preferred in modern home and commercial lighting systems. Because of its efficiency and output lumens, LED lighting systems are the favored option for residential, automotive, and outdoor lighting systems.

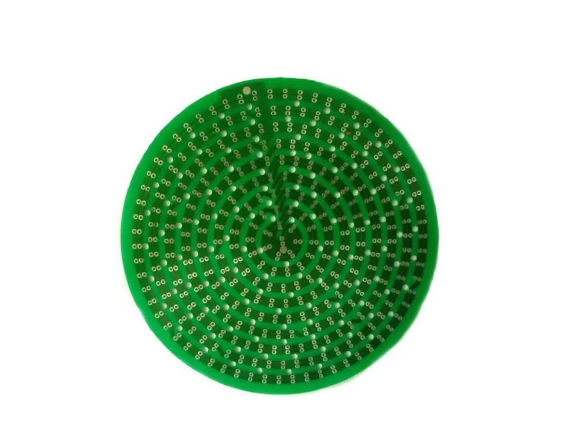

A power circuit is included in the printed circuit board on which LEDs are installed. Due to their propensity to generate excessive heat, LED PCB designs are distinct from other circuit board designs.

Aluminum PCB material, heat sinks, and other structural components are used in LED PCB design to remove thermal energy from the lighting board.

Are you interested in knowing some of the challenges that may be encountered during the use of LED PCBs? This article will give a detailed highlight of the possible LED PCB challenges.

The foundation of many LED lighting systems is an LED PCB. They have several noteworthy advantages, such as their small size, reduced power consumption, increased lifespan, great efficiency, and lack of mercury.

They have uses in a variety of gadgets, including laptops, smartphones, tablets, and other digital gadgets. To put it briefly, LED PCBs are particular kinds of printed circuit boards that are intended to be used in a variety of lighting modules and applications.

Below are some of the issues that LED lighting systems must deal with in their PCB designs.

The board's temperature rises due to heat produced by LED PCBs. High temperatures can negatively affect both the lifespan and color of LEDs if suitable thermal management measures are not taken.

Specific colors are delivered by LEDs in applications. LED lights exhibit color fluctuations as a result of temperature rise.

A major issue that needs to be addressed in the design of LED PCBs is a thermal constraint. To provide bright LED lights with a long lifespan and great efficiency, meticulous temperature control must be performed in essential LED applications.

The extended lifespan of LEDs is well-known. However, the lifespan of LED circuits may be shortened by temperature increases.

There are different types of LED PCB. These include:

Single-layer LED PCBs work well for straightforward circuits.

Two-layer PCBs can be used for increased stability, heat dissipation, and current handling capacity. Both through-hole mounting and surface mount techniques can be used to install components on double-sided PCBs.

Multilayer PCBs are the finest for building sturdy hardware LED lighting systems. LED PCBs are created as multilayer boards as the number of connections and circuit complexity rise.

The use of LED PCBs cannot be avoided because it is an integral component of many digital systems. This has resulted in their continuous need by the world market.

With years of experience in the industry, we have put several strategies in place to ensure that our customers get the best-desired products. So, in case you want to purchase your LED PCBs, you can always reach out to us to get them at prices that won't break the bank.

Contact us today for premium quality LED PCBs at very affordable rates.

By continuing to use the site you agree to our privacy policy Terms and Conditions.

Recruit global agents and distributors Join us