As the year of 2021 almost finished,do you have received your supplier info you that they have to adjust price and lead during this year. In that time, there have been many periods of shortages and price variations. None of those periods compares to the situation today. Seldom does a day pass without someone requesting a conference call to discuss the price increase. Everyone asks the same question: “What is the root cause?”

The first thing I wish to do is dispel the conspiracy theory that has been making the rounds. That theory is that the root cause of cost increases was that a certain Asian government believed that a new U.S. administration would remove the tariffs on electronics. Asia saw no reason for all the prices to fall since the United States had (seemingly) absorbed the tariff increases. Therefore, Asia wanted to create a general price increase that benefited all parts of the local supply chain by starting with the raw material. Whew! It is easy to see why this narrative has persevered. The reality is that the costing surge is a complex mix of economic events and not a single Machiavellian scheme. This conspiracy theory is the stuff of Tom Clancy novels, but not applicable to the present situation. (Sorry, Tom.)

You may ask what is root cause?the reason are COVID-19 and international division of labor is growing.

We’re not talk too much about COVID-19,it’s influence everywhere.

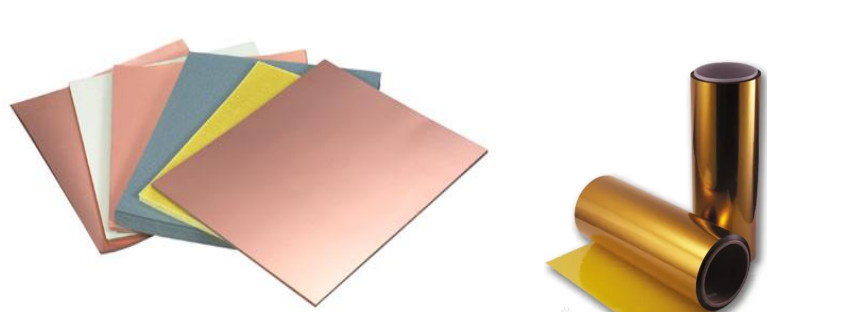

Most of PCB manufactory can not do laminate,they have to buy from laminate factory,when upstream supplier raise price,they have no choice,like domino effect.

A small digression is needed to examine the costing structure of a PCB. There are many different models circulating around and every PCB fabricator has their own version from which they derive their pricing. I would propose to distill all these down to a simple chart that is a composite of the most accurate of the models.

Here, the PCB costing into these three categories:

Raw materials, 47%

Technology processing, 43%

Yield, 10%

Of these three categories, the laminate is approximately 36%. Therefore, laminate is the number one cost driver in a PCB.

The category of raw materials (47%) consists of many different elements, including laminate, copper, films, coatings, etc. Each of these elements are part of a different commodity chain. The laminate is the most unusual because it crosses two commodities: metal and oil. Therefore, it has a complex cost model. An increase in copper demand impacts laminate. A change in global costing for oil impacts laminate.

As the holiday season is coming soon, VictoryPCB would like to take this moment to wish you a very Merry Christmas and a Happy Prosperous New Year. We sincerely thank you for your cooperation and trust this past year. Warmest wishes for peace, joy and happiness in the Holidays!

Any your questions or inquiry, please contact with us: sales@victorypcb.com

By continuing to use the site you agree to our privacy policy Terms and Conditions.

Recruit global agents and distributors Join us