Through-hole mounting has long been the standard in electronic assembly. It involves inserting component leads through holes in the PCB and soldering them on the opposite side. This method offers robust mechanical connections and high power handling capabilities. On the other hand, surface mount technology has gained immense popularity due to its ability to accommodate smaller components and achieve higher component density. SMT involves attaching components directly to the surface of the PCB, using solder paste and reflow soldering.

The following is a concise comparison between the through-hole and SMT methods for use as a decision-making reference guide for PCB designers.

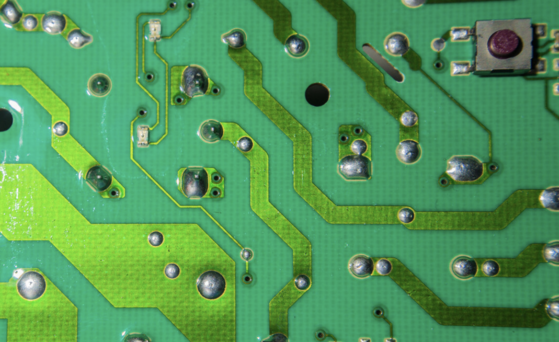

Through Hole Technology (THT) is a method of mounting electronic components by inserting their leads or pins into pre-drilled holes on a bare PCB. Before the emergence of SMT in the 1980s, through-hole technology was the industry-standard configuration method. However, Surface Mount is more efficient and less expensive, it leds many people to believe that THT would become obsolete.

Although through-hole components represent the older of the two technologies, there are still valid reasons for their usage. For example, assembling a through-hole PCB or a small batch of such boards requires minimal effort, as the holes that accommodate the component leads are spaced further apart compared to the surface pads used in SMT. The generous spacing, typically 0.100" or greater, facilitates hand-soldering of through-hole PCBs. Moreover, the likelihood of creating unintended connections (bridges) between the pins of a single component or between adjacent components is significantly reduced. This greatly simplifies troubleshooting and minimizes the need for rework once the fully assembled board is powered up.

Axial and radial leads are the two types of THT constituents. Axial lead constituents have wires attached to the component on both the front and the back. Radial constituents have the leads on one end side of the component.

Radial leads are preferable for densely packed boards because they take up less space than axial lead constituents, which fit snugly against the board.

Superior mechanical connections: THT provides stronger mechanical connections compared to Surface Mount Technology (SMT), making it ideal for components subjected to mechanical stress, such as connectors and transformers.

Ease of manual soldering: The spaced-out placement between the holes in THT allows for easier manual soldering of components, which can be beneficial during prototyping and testing stages.

Interchangeability: THT components are easily interchangeable, making them suitable for applications that require frequent component replacement, such as prototypes or testing.

Durability: THT connections offer robust interlayer connections, allowing THT components to withstand environmental pressures better than SMT components. This makes THT preferable for products exposed to intense thrust, vibrations, or high-temperature environments, including military and aerospace applications.

Time-consuming and costly due to the need for drilling holes in the bare PCB.

Restricts accessible configuration area on multi-layered boards as drilled holes must traverse all layers, making it costly for most applications.

Less efficient and dependable soldering methods (wave, selective, or manual) compared to SMT's reflow ovens.

Requires soldering on each side of the board, unlike SMT which only requires soldering on one side.

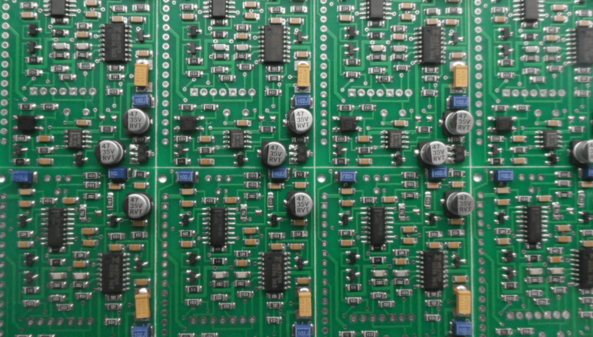

Surface Mount Technology (SMT) is the process of mounting components directly onto the surface of a printed circuit board (PCB). It was initially known as "planar mounting" and was developed in the 1960s, gaining significant popularity since the 1980s. Today, SMT is the standard method used in the manufacturing of electronic hardware, playing a crucial role in PCB design and production. It has greatly improved the overall quality and performance of PCBs while significantly reducing processing and handling costs.

SMT has become an integral part of PCB design due to its ability to enhance performance, reliability, and cost-effectiveness. By eliminating the need for drilled holes in the board, SMT allows components to be soldered directly onto the surface. These components are smaller in size and can be mounted on both sides of the board, enabling higher component density and resulting in more powerful and compact PCBs.

Improved Performance: SMT-fabricated PCBs exhibit excellent performance even under shaking and vibrational conditions, thanks to the secure connections between components and the board surface.

Cost Reduction and Efficiency: The absence of holes in SMT fabrication leads to significant cost reductions, minimal waste, and faster production time. SMT offers a quicker constituent configuration process, approximately 10 times faster than Through Hole Mounting (THM), due to the reliable soldering method using reflow ovens.

Space Utilization: SMT components eliminate the need for plated through-holes, utilizing small surface pads instead. This allows for drilling small vias directly beneath the SMT component leads, enabling Z-axis interconnections and efficient use of space. The reclaimed space can be utilized for placing additional components, leading to higher component densities and optimal use of available real estate.

Dual-Sided Mounting: SMT boards commonly utilize both sides of the PCB for component mounting. This further enhances the component density and offers more flexibility in component placement.

Mechanical and Environmental Stress: SMT may face challenges when used for components exposed to extreme mechanical, environmental, or thermal stress conditions. The solder joints in SMT can be more susceptible to failure compared to Through Hole Mounting (THM) under such conditions.

Unsuitability for Prototyping and Testing: SMT components are not ideal for small circuit prototyping or testing due to their smaller size and compact design. THM is often preferred for such applications as it allows for easier interchangeability of components during the prototype and testing stages.

SMT generally offers lower initial manufacturing costs, reduced labor and assembly costs, and easier rework and repair processes compared to THT. The smaller size and lighter weight of SMT components contribute to material cost savings and increased component density on the PCB. Automated assembly techniques in SMT reduce manual labor requirements, while rework and repair are simplified. Additionally, the wider availability of SMT components may result in cost advantages due to economies of scale.

SMT and THT differ in terms of component mounting, assembly process, accessibility, application suitability, and cost considerations in PCB assembly. SMT involves surface mounting of smaller components, enabling higher density and automated assembly, while THT requires manual insertion of components into drilled holes. SMT offers easier accessibility for testing and repair, making it suitable for high-volume production and miniaturized designs. THT excels in providing robust mechanical connections and is ideal for applications with high mechanical stress. SMT generally offers cost advantages for high-volume production, while THT may be more cost-effective for low-volume or specialized applications. The choice between SMT and THT depends on design requirements, assembly volume, component availability, and the intended application, often requiring a combination of both technologies to optimize PCB assembly processes.

| Surface Mount Technology (SMT) | Through Hole Technology (THT) | |

|---|---|---|

| Component | Smaller and lighter | Larger and heavier |

| Mounting | Mounted on the surface | Inserted through drilled holes |

| Assembly | Automated pick-and-place | Manual insertion and soldering |

| Accessibility | Easier access for testing, rework, and repair | May require desoldering and removal from both sides |

| Application | Ideal for high-volume production, miniaturized designs | Suitable for robust mechanical connections, high mechanical stress, and extreme environments |

| Cost | Generally cost-effective for high-volume production | More cost-effective for low-volume or specialized applications |

When choosing between SMT and THT, factors such as design requirements, production volume, cost budget, and application needs need to be considered. SMT is suitable for high-volume production, miniaturized designs, and automated assembly, offering higher component density and faster assembly speed. THT is suitable for applications that require robust mechanical connections, can withstand high mechanical stress or extreme environments, and may be more cost-effective for low-volume or specialized applications. Depending on the specific circumstances, a combination of SMT and THT technologies may be necessary to leverage the strengths of both approaches and achieve the optimal PCB assembly solution.

By continuing to use the site you agree to our privacy policy Terms and Conditions.

Recruit global agents and distributors Join us