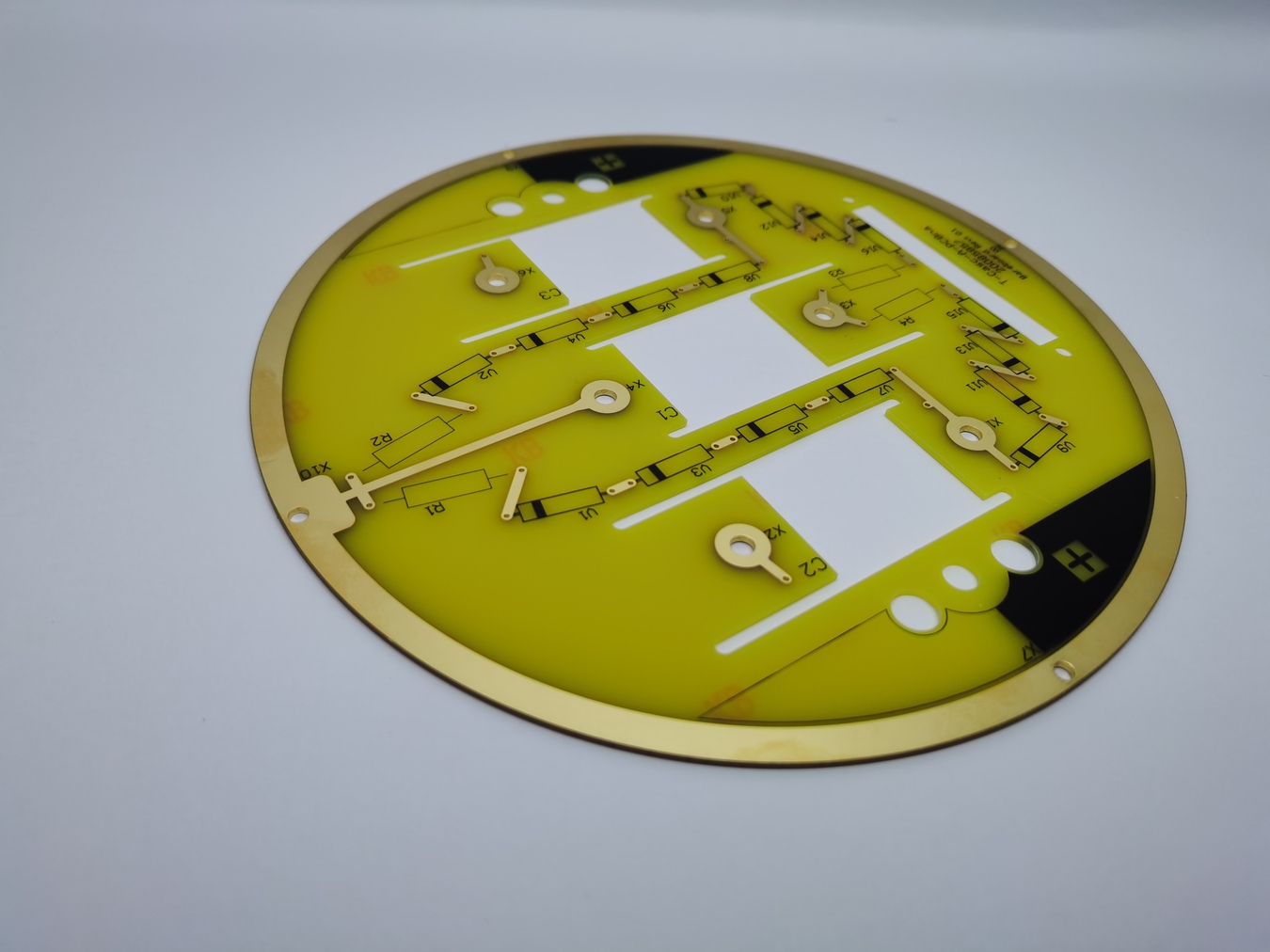

Have you seen a see-through circuit board before? These transparent pcbs play a key role in the field of optics. They allow you to look right through, even revealing transparent conductive lines and elements within. Most of these boards are flexible, made using PET film. Some are even ceramic.

VictoryPCB is a top PCB manufacturer providing all-in-one transparent circuit board production. In this article, we will introduce you to two types: transparent flex PCB and transparent glass PCB. So, let's dive into the world of transparent circuits together, we present transparent flex PCB and transparent glass PCB.

A Transparent PCB is a specialized type of circuit board that allows light to pass through, making the circuitry and components on the board visible. Unlike traditional PCBs that are typically opaque and conceal their inner workings, transparent PCBs are designed to offer a clear view of the circuit traces, components, and any other elements mounted on the board.

Transparent PCBs are created using materials that have transparency properties, such as certain types of plastics, glass, or ceramics. These materials are carefully chosen to ensure that the transparency doesn't compromise the functionality or durability of the board. The transparent nature of these PCBs brings both aesthetic and functional benefits, allowing for innovative designs and applications in various industries, including electronics, automotive, aerospace, and more.

Transparent PCB comes in both rigid and flexible variations, determined by the chosen construction materials. Flexible versions aren't synonymous with fragility; they possess distinct resistance characteristics.

Flexible transparent PCBs utilize materials like polyester and polyimide, which grant nearly 95% transparency. Each material boasts varying conductive and thermal attributes. Notably, polyimide-based flexible transparent PCBs exhibit resistance to heat and endure mechanical and electrical stress, allowing for diverse designs in shapes and sizes, even in colors like light blue, green, and more.

Rigid transparent PCBs, exemplified by ceramic PCBs, incorporate substrates like aluminum oxide or aluminum-magnesium amalgam. They offer approximately 80% transparency. These PCBs excel in moisture and dust resistance, contingent on the material.

In the PCB industry, three prevalent types of transparent PCBs exist based on material: Glass, Ceramic, and Transparent, each contributing to diverse design possibilities and resistance properties.

Related Article: PCB Material Types & Selection Guide

Glass, crafted from a blend of natural elements like soda, limestone, ash, and sand, stands as an eco-friendly choice due to its recyclability and abundant supply in nature.

For greater strength, tempered glass takes the spotlight. This type is fortified through processing and pre-stressing, resulting in heightened durability. Its ability to absorb shocks and impacts makes it valuable for challenging scenarios.

However, regular glass is not very sturdy, so you will most likely see tempered glass. Tempered glass is a reprocessed and prestressed glass to maximize durability. Besides, it has better shock and impact absorbing capabilities, making it useful for extreme applications.

Glass transparent PCBs also boast 360° luminescence. This quality enables light to radiate in all directions, enhancing its visual impact.

Enhanced Versatility: Transparent PCBs permit light to traverse, adding versatility to their application. This unique trait opens doors to creative design possibilities and improved user experiences.

Symmetry and Durability: The flat nature of transparent glass PCBs ensures symmetrical functionality with fewer flaws. This contributes to heightened efficiency and prolonged durability of the devices.

High Heat Resistance: Glass boasts impressive heat endurance, capable of withstanding temperatures of up to 1000 degrees. This attribute equips transparent glass PCBs to endure rigorous operating conditions.

Ease of Manufacturing: Transparent glass PCBs can be easily manufactured, drawing from recycled sources like sand and ash. This not only simplifies production but also lowers costs compared to alternatives like ceramic PCBs.

Resilience to Environmental Factors: Glass transparent PCBs exhibit resistance to heat, dust, and water, minimizing deformation risks. Their ability to endure extreme conditions ensures prolonged and reliable operation.

Efficiency in Production: The absence of heat sinking requirements streamlines the manufacturing process of transparent glass PCBs, leading to heightened production efficiency.

Ceramic Transparent PCBs are crafted from materials like aluminum oxide, alumina, and magnesium oxide. To enhance their resilience, manufacturers often infuse tiny alumina powder amounts into liquid resin, elevating its hardness.

In these PCBs, conductors are opaque, so transparent substrates with glass-based solder masks are commonly employed to boost transparency, achieving levels of around 75% to 85%.

Transparent ceramic PCBs usually blend materials like Aron, magnesium oxide, Al-Mg spinel, Yttrium oxide, and alumina. Incorporating fine alumina powder at levels like 5-10% boosts hardness from 6H to 8H.

Manufacturers may use oil-based or water-based alumina liquids. However, most opt for glass-based solder masks to achieve optimal transparency.

Electrical Insulation: Ceramic materials are excellent electrical insulators. Transparent ceramic circuit boards provide effective insulation between circuit traces and components, preventing short circuits and enhancing overall electrical performance.

high-temperature resistance: The inherent high-temperature resistance of ceramic materials makes transparent ceramic circuit boards suitable for applications that involve heat-intensive environments. Whether in industrial settings, aerospace applications, or electronics subjected to elevated temperatures, these circuit boards can maintain their functionality and reliability without significant degradation.

High Thermal Performance: Transparent ceramic materials have excellent thermal conductivity, great thermal conductivity of 26+W/mK, allowing them to efficiently dissipate heat generated by electronic components. This capability is crucial for maintaining optimal operating temperatures and ensuring the longevity of the components.

Small and stable CTE: Transparent Ceramic Circuit Boards typically exhibit a small and stable Coefficient of Thermal Expansion (CTE). This property is crucial for maintaining the structural integrity of the circuit board and the components mounted on it, especially in environments where temperature changes are common.

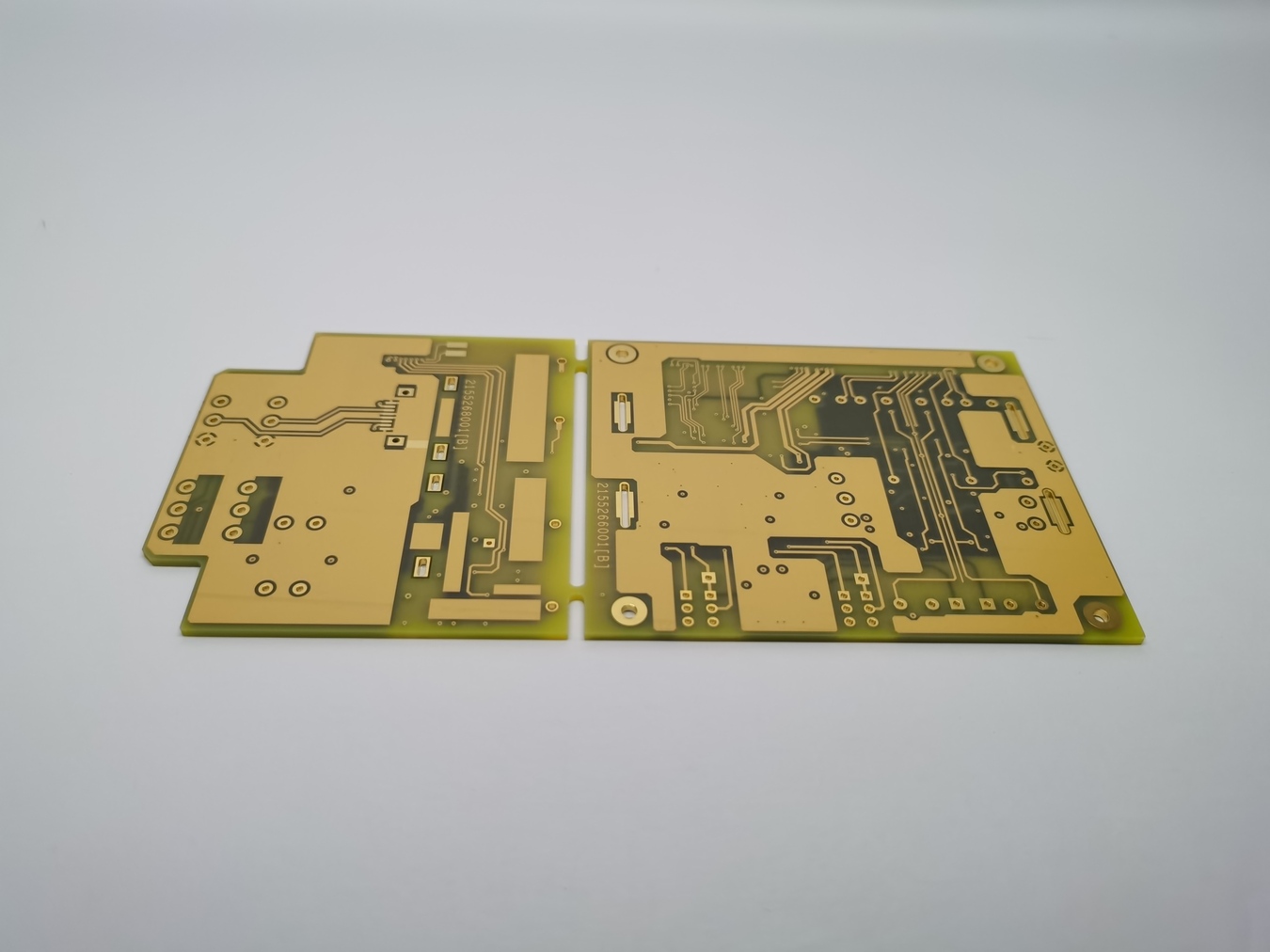

These PCBs are made using flexible materials like PET film or polyimide. They are bendable and suitable for applications where flexibility is required. Flexible transparent PCBs are commonly used in wearable technology, curved displays, and devices with irregular shapes.

PCB manufacturers can combine transparency and flexibility into one board by utilizing thin PET films. In addition, they can manufacture these circuit boards in various colors like light green, blue, white, etc.

Bendability and Flexibility: The primary advantage of Flexible Transparent PCBs is their ability to bend and flex. This makes them ideal for applications where traditional rigid PCBs would be impractical, such as curved displays, wearable technology, and devices with non-standard shapes.

Space Efficiency: Flexible Transparent PCBs can be designed to fit into tight spaces and conform to unique shapes. This allows for efficient utilization of available space in compact devices and designs.

Weight Reduction: Flexible Transparent PCBs are typically lighter than their rigid counterparts. This weight reduction can be crucial in applications where weight is a concern, such as aerospace and portable electronics.

Improved Durability: The flexibility of these PCBs allows them to withstand mechanical stress, vibrations, and impacts better than rigid PCBs. This increased durability is valuable in applications exposed to movement or physical stress.

Designing transparent PCBs involves specific considerations due to the unique properties and requirements of transparent materials. While the fundamental principles of PCB design apply to both transparent and standard PCBs, there are some differences and additional factors to keep in mind when working with transparent substrates. Here are some key pieces of advice for designing transparent PCBs.

Know the Material: Transparent PCBs use different stuff like Ceramics, Polymers or glass. Learn about their properties.

Place Components Wisely: Think about where traces and parts go to avoid blocking light.

Keep Cool: Transparent materials handle heat differently. Put hot parts where they won't overheat.

Signals Matter: These materials affect how signals move. Watch out for interference and matching issues.

Layer Setup: Consider layers for optics. Ask your manufacturer for the best setup.

Make It Buildable: Transparent materials can behave differently. Make sure your design won't warp or crack during production.

Clear Mask: Use clear solder mask for transparency and protection.

Easy Testing: Add markers or points for testing, as transparent PCBs can be hard to check visually.

Test First: Prototype and test before making lots, as these designs can be tricky.

Work with Experts: Collaborate with professional pcb manufacturer familiar with transparent PCBs for best results.

At VictoryPCB, we're committed to delivering cutting-edge solutions that meet the demands of modern industries. Our expertise in transparent PCB manufacturing enables us to bring your visionary designs to life, whether it's for optical applications, advanced displays, or unique electronic devices.

As you venture into the realm of transparent PCBs, remember that collaboration is key. Our team of skilled engineers and technicians is here to assist you in every step of the journey – from design optimization to material selection, from prototyping to mass production. We're not just a manufacturer; we're your partner in innovation. Don’t hesitate to contact us, we’ll be glad to support you.

By continuing to use the site you agree to our privacy policy Terms and Conditions.

Recruit global agents and distributors Join us