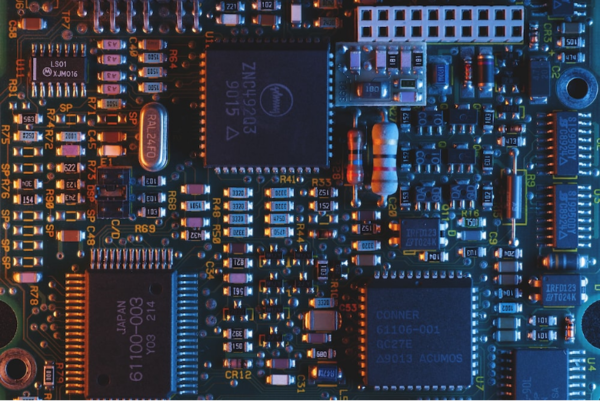

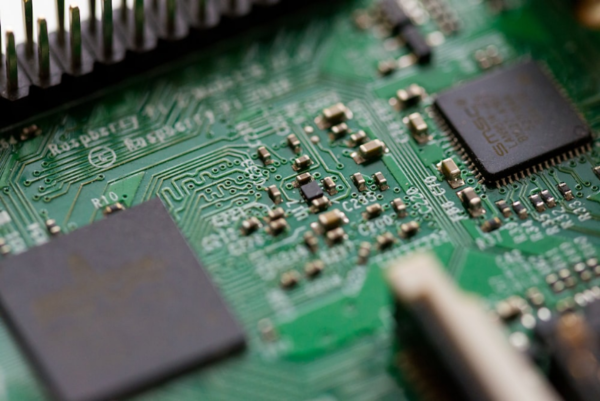

There are various PCB manufacturing processes ranging from fully automated production lines with thousands of PCB boards per day to small workshops where individual PCBs are produced. Boards are also often designed and etched at home by hobbyists and enthusiasts. There are also situations when electronic equipment fails. Sometimes it is enough to replace one element on the PCB , but more often you have to work a little more.

Many chemicals like flux, silicones, epoxies, Copper, adhesives, solder, and several other resins are used in the production of PCBs.

Copper is widely used in PCB manufacturing as it is a great electrical conductor. It is used to make the "traces," or conductive paths, that link the various components and parts on the board.

Additionally, it is utilized to make the solder pads, also known as contact points that are used to join components to circuit boards. Additionally, copper is used as a heat sink to receive and transmit heat produced by parts on the board.

Printed circuit boards (PCBs) are produced using chemical solder (PCBs). It is used to link electrically two or more conducting surfaces in an electrical circuit by joining them together.

Solder melts at low temperatures, making it possible to create electrical connections without the use of high temperatures or specialized machinery. It offers mechanical durability and stability and is also used to bind components and parts to the board.

In the manufacturing of PCB boards, a chemical compound called flux is used. It helps in lowering metal surface oxidation and strengthens the solder's ability to wet surfaces to form solid connections.

Additionally, cleaning the board's surface of any debris that could interfere with soldering is helpful.

Adhesives are essential to the production of PCB boards. They act as a barrier between the circuit board and the outside environment and help in the safety of components like surface-mount devices (SMDs).

Adhesives also assist in reducing the danger of electrical shocks by providing protection and bonding layers.

Silicones are quite popular in PCB board production as a lubricant and an insulator. They are applied to minimize EMI, friction between components, and heat protection for electronic components.

Additionally, they serve as an adhesive for joining parts to the board and filling up spaces between parts.

There are many reasons why epoxies are used in the production of PCB boards. They can be used to hold components to the board, offer electrical insulation between two or more layers, and shield the board from heat and moisture.

They can also be applied as a conformal coating to offer extra defense against dust and moisture.

Chemicals are used during PCB board production to guarantee the highest level of precision and quality in the boards' construction.

Chemicals are used to produce the necessary layers, the required forms, and features for the board, and to make sure that all parts are safely soldered and joined.

Etchant solutions are the most frequent chemicals used in the production of PCB boards. They are used to etch away extra copper layers and to give the board the appropriate forms and features.

Typically, these etchants are acidic liquids like ammonium persulfate or ferric chloride.

Flux is the second kind of chemical used in the production of PCB boards. The board's surface is cleaned with a flux to get rid of any oxidation or pollution that might be there. Additionally, it encourages strong solder contacts between the board and the components.

The next step is to use solder paste to make the connections between the board and the components. Tiny solder alloy particles suspended in a fluid matrix make up a solder paste. The solder connections are made by heating it after it has been applied to the board using a stencil.

The usage of these chemicals during the manufacture of PCBs helps to guarantee the highest level of precision and product quality.

Without these chemicals, it would be hard to design the complicated forms and features needed for the board, and it would be difficult to make reliable connections between the parts and the board.

When working with PCB boards, precision tweezers can come in handy. They can be used both during the soldering process and when desoldering the current board. The most useful are tweezers with a "sharp" tip, with which you can fit the element to the pad.

Most PCB boards are installed in devices of various kinds that need to be opened. In this case, tools such as screwdrivers with different nozzles, pliers, or wire cutters will come in handy. However, these are elements that are usually already in the electronics workshop.

Various types of chemicals are also useful for working with PCBs, among which we can list those already mentioned, in particular, isopropyl alcohol, fluxes, agents for restoring tips, and PCB varnish. In addition to these, rosin, which, like flux, facilitates the soldering process, "contact" spray or recovery liquid, for example, potentiometers or thermally conductive adhesives, will also be useful, allowing you to attach a heat sink to dissipate heat.

This adaptive base material system is designed with a polyimide resin suitable for any electronic package that may require maximum performance.

In particular, the heat resistance makes this material attractive for applications with high-temperature requirements, and the low coefficient of thermal expansion (CTE) provides excellent reliability of plated through holes. Polyimide film substrates consist of a high-strength and high-temperature polymer material.

The main advantage of film substrates is their low weight and the possibility of precise formation of conductors. This material has proven to be ideal for laser ablation in the fabrication of very small micro-perforated parts.

Physically, the material is very strong and is an ideal base for fine-pitch matrix applications. The polyimide provides excellent balance among physical, thermal, electrical, and chemical properties over a wide temperature range (from -270°C to +400°C).

Precise thickness control, exceptional film flatness plus improved adhesion, and excellent volume stability are standard features of polyimide films.

Depending on requirements, there are several options for the production of multilayer PTFE (Teflon®)/glass fabric substrates. The most common substrate production option is a multi-layer hybrid in which double-sided copper-clad PTFE-reinforced is bonded to a double-sided FR4 or FR4 sandwich structure using standard FR4 prepregs and an appropriate press cycle.

A multilayer structure made entirely of PTFE can only be created by a special pressing technique at very high temperatures. If HF properties are required for the dielectric, bonded films of TFE-hexafluoropropylene copolymer or chlorotrifluoroethylene are used.

Although the dielectric properties of the material may be a major factor in the selection of PTFE/glass fabric, users should be aware that the material has minimum copper peel strengths of ≈ 18 N/mm even for 17.5-micron copper foil.

One of the main disadvantages of the material is the difficulty in providing metallization of through holes. However, material suppliers and manufacturers claim that they have developed processes for the surface treatment of Teflon to allow it to be metalized.

Typically, LCPs have high mechanical strength at high temperatures, extreme chemical resistance, and a natural ability to slow down combustion.

Although LCP has a high coefficient of vertical thermal expansion, the material resists stress cracking at elevated temperatures in the presence of most chemicals, including aromatic and halogenated hydrocarbons, strong acids, gases, and other harsh industrial chemicals.

Partly due to the current price of the base material and the minimal experience of board manufacturers in its use, FLC is not widely used in semiconductor chip packaging. However, some experts argue that thin sheet material can serve as a highly effective backing substrate,

A hydrocarbon-based material filled with ceramic components and reinforced with fiberglass provides a controlled dielectric constant and low losses.

Unlike PTFE-based microwave materials, it does not require special processing to prepare through holes. Material suppliers claim that the cost of manufacturing boards and assembly is comparable to fiberglass. The base material has a dielectric constant ranging from 3.38 to 3.48 and is classified as UL94V-0 (nonflammable).

Appropriate prepregs have been developed to enable users to create high-frequency multilayer media using most of the standard FR4 processing technologies.

To sum up, the topic of workshop equipment and board handling is very broad. We must prepare a suitable workplace and equip it with tools and materials that will enable us to work accurately and safely. With this preparation, we can easily start working with PCB boards.

By continuing to use the site you agree to our privacy policy Terms and Conditions.

Recruit global agents and distributors Join us