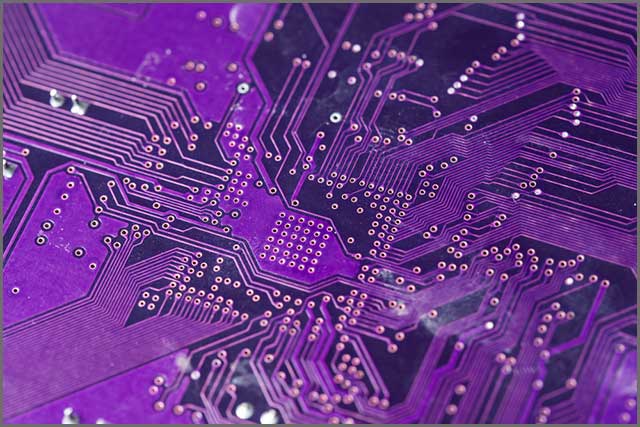

Nowadays, PCB circuit boards are widely used in various fields and almost all electronic equipment includes corresponding printed circuit boards. The main advantages of using circuit boards are that it greatly reduces errors in wiring and assembly and improves automation and production labor rates.

The PCB circuit board is mainly composed of pads, vias, mounting holes, wires, components, connectors, padding, electrical boundaries, etc. The main functions of each component are as follows:

Pads: metal holes for soldering component pins.

Vias: Metal holes used to connect component pins between layers.

Mounting hole: used to fix the printed circuit board.

Wire: Copper film for electrical network for connecting component pins.

Connector: components used for connection between circuit boards.

Filling: copper for ground network can reduce impedance.

Electrical boundary: used to determine the size of the circuit board, all components on the circuit board cannot exceed the boundary.

At present, there are still many buyers who have doubts about the color of PCB board. What color of a PCB board is better? What are the different colors of the PCB board and how it affects the performance of the product?

First, as a printed circuit board, the PCB mainly provides interconnections between electronic components. Color and performance are not directly related and the difference in pigments will not affect the performance of electrical appliances. The performance of the PCB board is determined by factors such as the materials used (high Q value), wiring design, and several layers of boards. However, in the process of washing the PCB, black board is easy to cause color difference. If the raw materials and manufacturing processes used by the PCB factory are slightly different, the PCB defect rate will increase due to the color difference. This directly results in increased production costs.

Secondly, the raw materials of PCB are everywhere in our daily life, that is glass fiber and resin. Glass fiber and resin are combined and hardened into a heat-insulating, insulating board. This is the PCB substrate. Of course, the PCB substrate made of glass fiber and resin alone cannot transmit signals. Therefore, manufacturers will cover the surface with a layer of copper on the PCB substrate, so the PCB substrate can also be called a copper-clad substrate.

Because the black PCB circuit traces are difficult to identify, it will increase the difficulty of maintenance and debugging in the R & D and after-sales stages. Generally, if you do not have a strong RD (R & D) designer and a strong maintenance team, you will not easily use the black PCB of. It can be said that the use of black PCB is a brand's confidence in the RD design and post-maintenance team. It is also a manifestation of the manufacturers' confidence in their own strength.

By continuing to use the site you agree to our privacy policy Terms and Conditions.

Recruit global agents and distributors Join us