Have you ever imagined why many low-density electrical and electronic equipment are durable and last for a long time? Many times, people wonder how it is possible for a small device to perform high-degree actions without a quick development of an unknown fault.

In addition, people often spill out the phrase, "small but mighty" without knowing what backs up the mightiness of such equipment. Without further ado, the unique material is known as the single-layer PCB.

Some areas of application of single-layer PCB include camera systems, calculators, printers, solid-state drives, led lighting, power supplies, switches, inductors, and capacitors, among several others.

In case you are wondering what the single-layer PCB is all about, this article will give you a detailed breakdown of everything you need to know about the single-layer PCB.

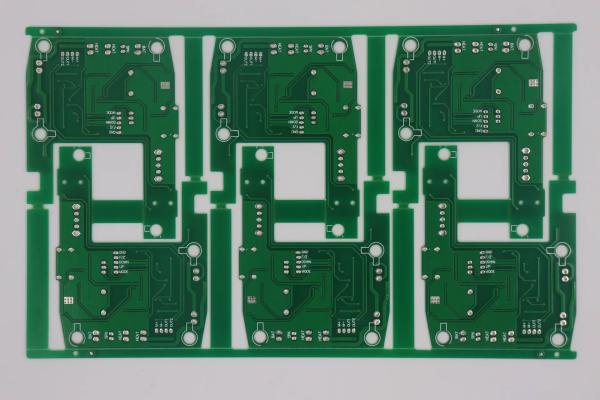

One layer of conducting material is present on one side of a single-layer PCB, sometimes referred to as a single-sided PCB. The other side of the board is utilized to attach various electronic components to the board.

When minimal prices are necessary, single-layer PCB is frequently employed in the printed circuit board design for several diverse electronic applications. Additionally, different materials, including paper-reinforced phenolic resin with copper foil and glass fiber reinforcement, have been used to create single-layer PCBs.

A single-layer PCB has several benefits and uses. These include their high degree of adaptability, ease of installation, low cost, and low maintenance requirements.

They are a particular kind of single-layer PCB that is constructed from a rigid material like fiberglass. Although the circuit boards are rigid, they keep the circuit from bending and breaking.

These are the kinds of single-layer PCBs that use flexible materials as opposed to stiff ones.

These are the single-layer PCBs that are typically used for high-frequency PCBs that operate at gigahertz. Teflon or polyphenylene oxide (PPO) is used to create the boards.

They are a particular kind of single-layer PCB that combines plastic and fiberglass in its construction. Thus, plastic and fiberglass are related to a single layer.

This special category of single-layer PCBs is known as single-layer PCBs with an aluminum substrate. The boards' layout is relatively similar to that of copper-backed PCBs, however, there is a distinction because aluminum PCBs are used as the substrate in place of copper.

Without any doubt, the use of single-layer PCBs in the electronics industry cannot be underestimated. While they are always improvements in technology, single PCB layers still prove efficient for use in calculators, capacitors, resistors, transformers, and so on.

Therefore, in case you want to purchase your single-layer PCBs, you can always reach out to us for us to discuss your budget. Our goal since inception is to offer quality products to our customers.

Contact us today for your high-quality single-layer PCBs at very affordable rates.

By continuing to use the site you agree to our privacy policy Terms and Conditions.

Recruit global agents and distributors Join us