As a matter of course, the pattern of the board is made of copper. We shall talk about copper used for circuit boards.

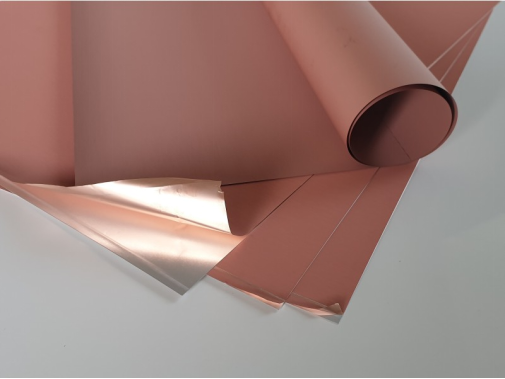

Two types of copper foils are used for the copper used in substrates. One is "electrolytic copper foil" used for rigid boards, and the other is "rolled copper foil" used for flexible and high-current boards.

Electrodeposited copper foil is made by energizing a bath of copper sulfate (Sn2SO4) and processing the copper deposited on the cathode (stainless steel, etc.) into a sheet. The copper foil on the cathode side becomes the surface of the substrate, and the other side is roughened by soft etching and comes in contact with the base material.

The purpose of roughening is to improve adhesion to the base material. The resin itself adheres easily with epoxy resin, but when joining with phenolic resin, it does not have adhesive properties, so an adhesive is used to join. On the other hand, rolled copper foil is made by heating an ingot with a purity of 99.9% or higher and then rolling it.

Electrolytic copper foil is used for ordinary rigid boards, and rolled copper foil is used for flexible boards and copper foils exceeding 3 ounces.

Since resin and metal are stuck together, it is a place to worry about whether it is firmly attached. The standard prescribes the test method for the peeling strength of the bonding strength between resin and copper foil. It states that the test should be conducted at room temperature, after soldering, and during heating. See the JIS standard for details.

Recently, there have been cases in which foreign-made base materials have been used. Still, in some cases, the adhesion strength between the copper and the base material and various other properties are inferior to domestic ones.

The material is indeed cheap, but if you use it, please pays attention to the characteristics and reliability data of the substrate. It may be listed in the material catalogue, so checking it is a good idea.

The thickness of the copper foil is mainly 18um, 35um and 70um. 18um is often used for double-sided boards plated with copper in manufacturing raw boards, the surface layer of multilayer boards, etc., and 35um is used for single-sided boards that are not plated, the inner layers of multilayer boards, and patterns with high current values.

70um is used a lot. In addition, thin ones such as 12um (9um) are used for ultra-high density patterns such as build-up boards and thick ones such as 105um are used for high current patterns.

Thicker copper foil is also used for boards with large currents. One ft2 of 35um thick copper foil weighs 1 ounce (305g), so we call 35um copper foil 1-ounce copper. 18umμ is 1/2 ounce, 70umμ is 2 ounces. Recently, the price of copper has soared, and the substrate price seems to be rebounding.

In the past, 70um material was often used for the power supply and GND (inner layer) of multilayer boards, but recently, 35um material has also come to be used quite frequently.

I mentioned the reliability evaluation data of the "substrate" in another column the other day, but what about the reliability of the "base material"? As I mentioned in the previous section, even if the manufacturing method of the base material is the same, the performance differs depending on the manufacturing company.

For example, with the expansion of needs for high-heat-resistant substrates, FR-4 materials, which are cheaper than conventional BT resin substrates and have a high Tg (glass transition temperature), have been developed, and base material companies are working to differentiate themselves.

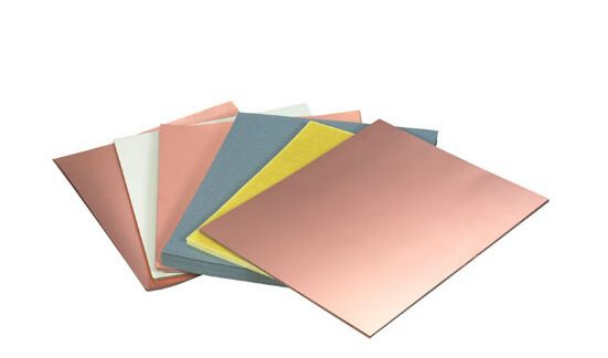

Copper Clad Laminate, or CCL (Copper Clad Laminate), is a base material for manufacturing printed circuit boards. Copper-clad laminates are made by impregnating glass cloth (glass cloth) woven with highly insulating glass fibre with resin. After that, a plate-shaped resin sheet is made by heat processing and copper foil is placed on the top and bottom of it, and it is completed by heating and pressing with a press machine.

The stretchability, strength, heat resistance, and low dielectric constant of the glass cloth vary depending on the composition and weave of the glass and the composition and amount of the impregnated resin. Therefore, this copper-clad laminate is the most important for the characteristics of printed circuit boards.

Inexpensive copper-clad laminates generally use highly versatile glass cloth and resin. It is necessary to choose cloth and resin.

Copper-clad laminates are not manufactured by substrate manufacturers but are purchased from chemical material manufacturers that specialize in manufacturing copper-clad laminates.

Although it is not necessary for a double-sided board, an insulating material called prepreg (PP) is required for a multilayer board with four or more layers.

This prepreg is a resin sheet made by impregnating glass cloth with resin and curing it to a semi-cured state. When manufacturing a multilayer board, if heat and pressure are applied to a copper-clad laminate with prepregs stacked on top and bottom of the copper-clad laminate and further sandwiched between copper foils, the semi-cured resin of the prepreg will re-melt and become adhesive.

As with copper-clad laminates, the composition and weave of the glass cloth and the composition and blending amount of the impregnated resin affect the stretchability, strength, heat resistance, and low dielectric constant of the prepreg. It is necessary to select the type with the board and set

Circuit board manufacturers describe Prepreg as PP and often abbreviated as "Puri".

The circuit board's circuit pattern (conductor layer) that conducts electricity is made of copper foil. Copper foil is like the copper version of aluminium foil and is made of electrolytic copper foil with a purity of 99.8% or higher made by electrolysis.

One side of the copper foil made by electrolysis is surface-treated to improve adhesion with resin. The treated surface is rough with fine irregularities, and these fine irregularities improve the adhesion to the prepreg.

The copper foil used for substrates has various thicknesses depending on the application. For example, 35 µm thick copper foil is used for analogue circuits with relatively high ampacity, and 18 µm thick copper foil is used for digital circuits. Even thinner copper foils have been used in recent digital circuits.

Solder-resist ink is an insulating ink that protects the surface of printed circuit boards. Solder is solder and resists tolerant, and it prevents solder from adhering to areas other than the mounting area when mounting parts on a printed circuit board. It also permanently protects circuit patterns on the board from moisture, heat, and dust and maintains insulation.

Solder resist ink is an ink that reacts to light and semi-cures and is finally cured by heat treatment. Unlike normal ink, it reacts to light and heat, so it needs to be handled with care.

In addition to colour, characteristics such as high heat resistance, microfabrication support, flexibility support, etc., vary depending on the difference in the chemical materials contained in the ink. Therefore, solder-resist inks with completely different characteristics are used for the substrates of automobiles and smartphones.

The basic materials for printed circuit boards are the above four types, but it is necessary to select the appropriate type according to the characteristics required for the board. There are dozens of manufacturers of copper-clad laminates alone, and each company has dozens of product lineups. There are infinite combinations, so it would be a good idea to consult with the board manufacturer and decide.

By continuing to use the site you agree to our privacy policy Terms and Conditions.

Recruit global agents and distributors Join us