The development of integrated and functional microelectronics requires the use of small-sized components. One way to achieve this goal is to manufacture a multilayer printed circuit board (MPB). The product consists of 5 or more dielectric layers. When using multilayer PCB, the dimensions of the final device are reduced, and the design complexity increases significantly.

Multilayer printed circuit boards are made from FR4, FR4 High Tg, FR5, polyimide, fiberglass, alumina ceramics, Rogers/Taconic/Arlon microwave laminates and other composite materials. The sites are covered with immersion gold, tin or silver, lead-free or hot tinning technology is used.

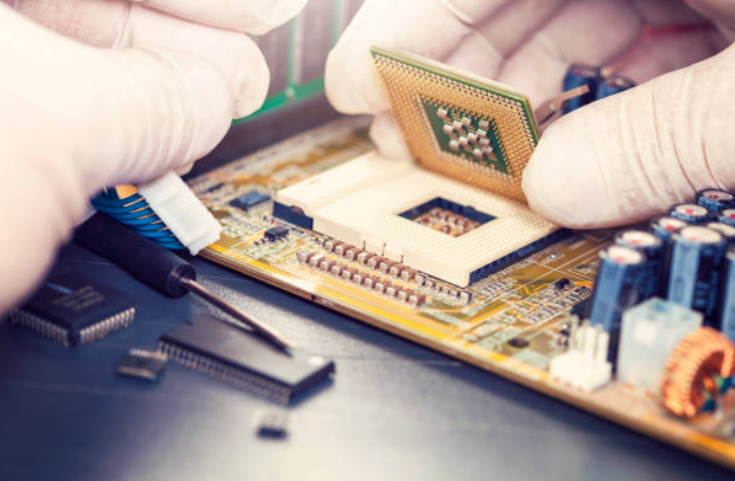

Image of printed multilayer boards in the production of MPP, several dielectric plates are used. Design features depend on the type of product. For example, flexible boards are made from polyimide. It provides the necessary plasticity of the carrier with resistance to mechanical stress. There are several methods for assembling multilayer boards:

The method is based on the technology of metallization of holes in double-sided printed circuit boards. It is used when creating products with medium or high rigidity.

The main advantage of this technology is the absence of restrictions on the maximum number of layers.

This technique provides a high packing density. Interlayer transitions can be made at any point of the dielectric, regardless of the location of the interlayer connections. This method is used to produce devices with a high degree of reliability, for example, components for spacecraft control systems.

This technology enables high component density with shorter communication lines. The finished product is resistant to environmental influences, because. All conductors are in a monolithic dielectric.

We manufacture boards up to 40 layers. The thickness of products is from 0.2 to 10 mm. High-density multilayer boards can be produced with hidden or blind vias. Holes can be filled with copper, compound or solder mask. There is the possibility of passing electrical control, control of wave resistance.

Do you want to know the price of manufacturing a multilayer board? Send project files. We will contact you after the engineers review your input.

Multilayer printed circuit boards allow you to place electronic components on the outer sides of the base with maximum density, and hide electrical circuits on the inner layers with vias. The number of layers of a complex multilayer printed circuit board can reach 32. Along with rigid boards, flexible MPPs on a polymer base are manufactured.

Components and tracks are placed as tightly as possible compared to OPP and DPP. Multilayer boards can significantly reduce the size of complex electronic devices.

The length of the conductors connecting the components is minimal - this increases the speed of data processing and makes the device more efficient and convenient to use.

Due to the special assembly technology, complex multilayer printed circuit boards are durable and reliable in operation.

High price: But the development of technology makes it possible to reduce the cost and speed up the process of manufacturing multilayer printed circuit boards.

The need to use sophisticated precision manufacturing equipment and employ highly skilled personnel is required. It is necessary to check the quality of the equipment regularly to minimize the risk of defective products and the associated financial losses.

Lengthy manufacturing process and the need for careful testing of finished MPPs. Quality control requires trained professionals.

The inability to repair multilayer printed circuit boards. Many parts of a multilayer board are practically inaccessible to replacement without the use of special equipment. MPP repairs are carried out by professionals.

One of the key disadvantages of MPP is the high cost of manufacturing products. A complex multilayer printed circuit board will cost less if:

· Avoid unnecessary complication of the project; reduce the number of layers and conductors to the required minimum.

· Optimize the number of holes - hidden, blind.

· Give preference to a structure with internal cores.

Use a combined structure only in cases where it is impossible to do without it.

The miniaturization of electronic components in combination with the high density multilayer PCB makes it possible to make electronic devices smaller and lighter.

Companies specializing in the manufacture and sale of printed circuit boards successfully solve the problems associated with piece, small-scale or mass production of PCBs with typical characteristics.

But in some cases, customers need to manufacture a printed circuit assembly with non-standard parameters. This applies to specific performance characteristics, the number and configuration of electronic components, special requirements for the base material.

Printed circuit boards in China are classified as non-standard if they meet the following conditions:

They are distinguished by increased complexity due to the high density of connections, smaller pattern parameters compared to typical ones. The manufacture of such boards requires more careful work of specialists, additional verification of the correctness of the project and the quality of execution at all stages.

Metallization of the butt is provided. Boards with a metallized end are in demand for organizing processes for which electromagnetic compatibility, signal integrity, and efficient cooling are important.

Metallized half-holes with a diameter of 0.8 mm or more are provided, which serve as leads for further mounting a printed circuit board on another board using SMT technology.

The base is made of aluminum or other metal. Such boards are characterized by increased strength and provide the most efficient heat removal from the components.

Microwave and RF printed circuit boards, made on the basis of fluoroplastic, which has a dielectric constant less than 3 and the smallest dielectric loss tangent. Such printed circuit boards are characterized by increased thermo mechanical stability.

The first stage is preparatory. At this stage, the circuit diagram of the printed circuit board is imported into the computer-aided design (CAD) database; diagrams of all components, their location and purpose of the conclusions are added. The number of PCB layers, hole diameter, board accuracy class, etc. are also determined.

The second stage in the development of printed circuit boards is design. The developer determines the dimensions and contour of the board, the maximum allowable height of the components, the location of the holes for fasteners. At this stage:

· Components are placed

· Tracing is performed

· Checking for errors

· The mechanical properties of the board are calculated.

At the third stage of PCB development, the output design documentation is created. The file format must comply with the requirements of the PCB manufacturer.

· Type of dielectric from which the base is made;

· Hole diameters;

· Via characteristics (open/solder mask closed/tinned);

· Number and type of electroplating areas;

· Soldermask type, color;

· The presence / absence of the need for labeling;

· The principle of contour processing (scribing / milling).

The development of printed circuit boards is carried out taking into account many factors, which include:

· The choice of dielectric base material depending on the type and operating conditions of the board. It can be fiberglass, laminates, ceramics, aluminum, flexible polymers.

· Number of metallization layers: Complex printed circuit assemblies have additional inner layers.

· Electrical connections: To obtain electrically conductive tracks on the surface of the board, excess copper of the metallized coating is removed.

· Transition holes: Connect the metallized layers of two-layer and multilayer printed circuit boards. Holes can be through, deaf, hidden. Pinholes can be used to connect the outer layer to the inner layer.

· Solder mask: A protective layer that prevents the solder from spreading.

Microwave and RF printed circuit boards made on a ceramic base, which is made of a material based on hydrocarbon ceramics. Such a base combines the main advantages of fluoroplastic and ceramic materials - it has high rigidity, maintains stable electrical and mechanical parameters in a wide temperature range.

Multilayer printed circuit boards for the manufacture of planar transformers. In such cases, PP is used instead of wire winding and frame assembly.

The design of each board with non-standard parameters requires special attention and the search for optimal solutions, including taking into account the availability of certain materials and components, the technological equipment of the manufacturer.

The total cost in the manufacture and sale of printed circuit boards is calculated taking into account:

· Complexity of design and execution

· The cost of materials

· The volume of the ordered batch of printed circuit boards

The introduction of modern technologies, advanced production equipment allows Victory PCB to produce high-density multilayer printed circuit boards of any complexity.

For the development of software, automated programs are used, the use of which makes it possible to create a project in which all rules and restrictions are strictly observed. Finished products undergo visual quality control and electrical control using high-tech equipment.

By continuing to use the site you agree to our privacy policy Terms and Conditions.

Recruit global agents and distributors Join us