Choosing the right printed circuit board (PCB) material is crucial for any electronic project or product. The PCB material directly affects the performance, durability, and overall cost of the circuit board. Among the various options available, two commonly considered materials are aluminum PCBs and FR4 PCBs. In this article, we will explore the key differences between these two materials, helping you make an informed decision when selecting the ideal PCB material for your specific needs.

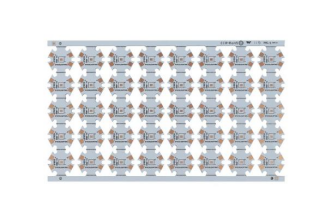

Aluminum PCBs are aluminum based CCLs (CCL is a type of base material of PCBs). Aluminum PCBs are actually quite similar to FR4 PCBs. The basic structure of Aluminum PCBs is four layered. It consists of a layer of copper foil, a dielectric layer, an aluminum base layer and aluminum base membrane.

Excellent Thermal Management

Aluminum PCBs excel in dissipating heat generated by electronic components. The high thermal conductivity of aluminum allows for efficient heat transfer, reducing the risk of overheating and ensuring optimal performance of the circuit board. This advantage makes aluminum PCBs particularly suitable for applications with high-power components or those operating in demanding thermal environments.

Lightweight and Durable

Aluminum is a lightweight material, making aluminum PCBs significantly lighter compared to traditional PCB substrates like FR4. This weight reduction is particularly advantageous in industries where weight considerations are critical, such as aerospace or automotive applications. Despite their lightweight nature, aluminum PCBs retain excellent durability and mechanical strength, with the ability to withstand mechanical stress, vibrations, and impact.

High Thermal Resistance

Aluminum PCBs offer excellent thermal resistance, allowing them to withstand high operating temperatures. This makes them suitable for applications that require exposure to elevated temperatures or thermal cycling.

Improved Signal Integrity

The electrical properties of aluminum PCBs contribute to enhanced signal integrity. They offer low electrical impedance and provide efficient transmission of signals, minimizing signal loss, distortion, and electromagnetic interference. This advantage is valuable in high-frequency applications or those requiring precise signal transmission.

Cost-Effective

Aluminum is a readily available and cost-effective material, making aluminum PCBs a viable option for budget-conscious projects. Compared to other specialized materials, aluminum PCBs can offer cost savings without compromising on performance or reliability.

Compatibility with Standard PCB Manufacturing Processes

Aluminum PCBs can be manufactured using standard PCB fabrication processes, allowing for seamless integration into existing manufacturing workflows. This compatibility simplifies production and reduces manufacturing costs.

It's important to note that while aluminum PCBs offer numerous advantages, their suitability depends on specific application requirements. It is recommended to carefully evaluate the project needs and consult with PCB manufacturers or experts to determine if aluminum PCBs are the optimal choice for your particular application.

Aluminum PCBs (Printed Circuit Boards) have emerged as a popular choice in the electronics industry, owing to their unique set of properties and advantages. From their exceptional thermal management capabilities to their lightweight nature, aluminum PCBs offer a wide range of applications across various sectors.

Whether it's power electronics, automotive systems, LED lighting, or industrial controls, aluminum PCBs are instrumental in efficiently dissipating heat, ensuring optimal performance and extended lifespan of electronic components.

FR4 is a class of printed circuit board base material made from a flame retardant epoxy resin and glass fabric composite. FR stands for flame retardant and meets the requirements of UL94V-0.

FR4 PCBs offer several advantages that make them a popular choice in the electronics industry. Here are the key advantages of FR4 PCBs.

Widely Available and Standardized

FR4 is the most widely used substrate material for PCBs, making it readily available in the market. It has become an industry standard, ensuring compatibility with standard manufacturing processes and equipment. The abundance and standardization of FR4 PCBs contribute to cost-effectiveness and ease of procurement.

Good Electrical Insulation Properties

FR4 offers excellent electrical insulation properties, which are crucial for reliable circuit operation. The material has high dielectric strength, ensuring effective isolation between different circuit layers and components. This property prevents signal leakage, interference, and short circuits, contributing to the overall functionality and safety of electronic systems.

Mechanical Durability

FR4 PCBs exhibit good mechanical strength and durability, making them resistant to environmental conditions, vibrations, and mechanical stresses. They can withstand temperature variations and physical impacts without compromising performance.

The main characteristics: The heat dissipation of aluminum and FR-4 is compared with the heat resistance of the substrate: the aluminum is aluminum basis, and the FR-4 is a transistor. Due to the different heat dissipation of the basis, the testing data for temperature rise is different.

From the comparison of the Aluminum PCB and the FR-4 PCB, due to the high heat dissipation of the metal substrate, the wires are significantly improved, which illustrates the high heat dissipation characteristics of the Aluminum from another perspective. The heat dissipation of the Aluminum is related to the thickness of its insulating layer and thermal conductivity. The thinner the insulating layer, the higher the thermal conductivity(but the lower the voltage resistance).

Aluminum has higher mechanical strength and toughness, which is better than FR-4.So large-area printed boards can be made on Aluminum substrates, on which large components can be mounted.

In order to ensure the performance of the circuit, certain components in electronic products need to be protected from radiation and interference of electromagnetic waves. The Aluminum can be used to shield electromagnetic waves.

Due to the thermal expansion of FR-4, and particularly the thickness of the board, the quality of the metallized holes and wires will be affected. The main reason is that the thermal expansion coefficient of copper in the raw material is 17*106cm/cm-C, and the FR-4 sheet is 110*106cm/cm-C, the difference is large, and it is easy to cause heated substrate expansion and change copper wire as well as Detrimental effect of metal hole rupture on product reliability. The thermal expansion coefficient of the Aluminum is 50×106cm/cm-C, which is smaller than that of the ordinary FR-4 board and close to the thermal expansion coefficient of the copper foil. This helps to ensure the quality and reliability of the printed circuit board.

The aluminum substrate shines in the LED lighting electronics industry because of its excellent heat dissipation performance and dimensional stability, and the processing controllability of the FR4 glass fiber PCB board is irreplaceable in HDI high-density interconnection and high-end electronic technology.

Selecting the right printed circuit board (PCB) material is a critical step in the design and development of electronic systems. The choice of PCB material directly affects the performance, reliability, and cost-efficiency of the final product. Two commonly considered options in the industry are aluminum PCBs and FR4 PCBs.

Aluminum PCBs have gained popularity due to their exceptional thermal management capabilities, lightweight nature, and durability. These characteristics make them suitable for applications that demand efficient heat dissipation, such as power electronics and LED lighting systems. On the other hand, FR4 PCBs, made from a fiberglass-reinforced epoxy laminate, offer advantages such as cost-effectiveness, electrical insulation properties, and widespread availability. They are commonly used in consumer electronics, telecommunications, and industrial control systems.

Victory PCB is a professional PCB manufacturer of PCB fabrication. Our PCB products includes heavy copper PCB, double-sided PCB, FR-4 PCB and on on. With advanced PCB production and testing equipments, and well-found quality system to monitor throughout the whole manufacturing to assembly, we can ensure the stable and excellent quality of the production process to meet customers' requirements. If you have any questions about our company or products, please feel free to let us know.

By continuing to use the site you agree to our privacy policy Terms and Conditions.

Recruit global agents and distributors Join us