Victory PCB focuses on the development of special types and special materials products. Three Rogers sheet samples have been completed, including multi-layer mixed pressure, yin-yang copper high frequency, and conventional Rogers products. In the future, the production control SOP of Rogers products will be improved to facilitate subsequent batch production, ensure quality and meet customer delivery dates. Below are some brief descriptions of 3 product types.

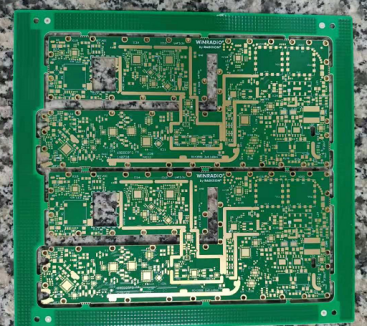

Model: S6I55649A0

Plate thickness: 1.6+/-0.16mm

Plate: Rogers4350+FR4

Solder mask: green oil

Surface Treatment: Immersion Gold

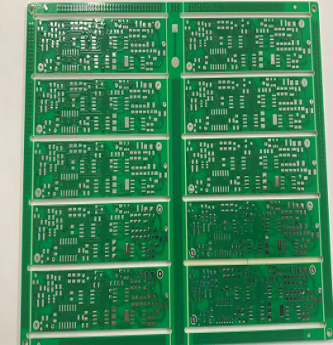

Model: S2P56437A0

Plate thickness: 1.6+/-0.16mm

Plate: ROGERS4350

Solder mask: green oil

Surface treatment: lead-free spray tin

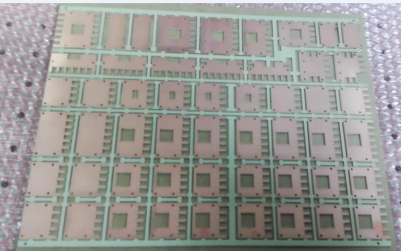

Model: S2O54826A0

Plate thickness: 0.735+/-0.1mm

Plate: ROGER AD1000L

Solder mask: none

Surface treatment: none

It is forbidden to grind the board mechanically. The mechanical external force will cause the deformation of the board. The pre-treatment needs to use chemical cleaning. In addition, pay attention to cleaning the table and board during transportation and placement to prevent the generation of pits and pits.

When picking and placing the board during the production process, it is recommended to use the manual method to avoid the crease problem caused by the automatic device.

When taking the board, it is forbidden to take only one board edge or board corner; it is recommended to hold two parallel opposite sides of the board with both hands.

When stacking, the board should be separated by a soft cushion, such as the release paper shipped with the board by Rogers, and the height of the stack should be controlled.

For more information, please do not hesitate to contact us directly.

By continuing to use the site you agree to our privacy policy Terms and Conditions.

Recruit global agents and distributors Join us