A printed circuit board (PCB) is an electronic circuit used to connect electronic components. It also provides mechanical support for various electronic components assembled in the device. For inefficient thick-wired circuits, PCB is a very effective alternative, because thick-wired circuits are inefficient and take up more time and space to set up. Demand for PCBs has grown exponentially over the past few years.

Market analysis conducted by procurement information provider predicts that the PCB industry will witness the highest penetration in the Asia Pacific region in the coming years. The Asia-Pacific region is a hub for technological innovation, with the largest professional PCB manufacturer.

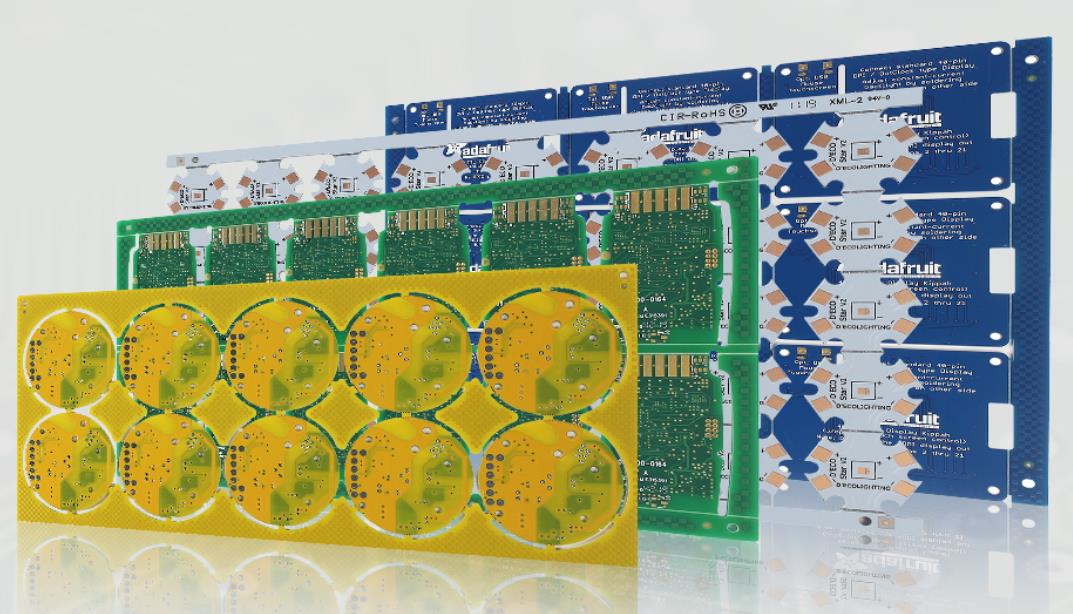

PCB is the traditional name for the bare board of which you supply us with the layout data and which you use to mount your components on once we have delivered it to you.

PCB is used to mechanically support and electrically connect electronic components using conductive pathways, tracks or signal traces etched from copper sheets laminated onto a non-conductive substrate.

When the board has only copper tracks and features, and no circuit elements such as capacitors, resistors or active devices have been manufactured into the actual substrate of the board, it is more correctly referred to as printed wiring board (PWB) or etched wiring board. Use of the term PWB or printed wiring board although more accurate and distinct from what would be known as a true printed circuit board, has generally fallen by the wayside for many people as the distinction between circuit and wiring has become blurred.

Today printed wiring (circuit) boards are used in virtually all but the simplest commercially produced electronic devices, and allow fully automated assembly processes that were not possible or practical in earlier era tag type circuit assembly processes.

A PCB populated with electronic components is called a printed circuit assembly (PCA), printed circuit board assembly or PCB Assembly (PCBA). In informal use the term “PCB” is used both for bare and assembled boards, the context clarifying the meaning. The IPC preferred term for populated boards is CCA, circuit card assembly. This does not apply to backplanes; assembled backplanes are called backplane assemblies by the IPC.

The professional PCB manufacturer can make a variety of tools used in our daily lives. From smartphones to the electronic devices we use at home. Some of the leading manufacturing companies that are increasingly discovering the use of PCBs include:

Consumer electronics products

Medical equipment

Automobile industry

Aerospace and Military

telecommunications

Industrial motor

Semiconductor

networking

A PCB is a printed circuit board, which is the mechanical support for an electronic component, connecting the component to a function.

Electronics are very common and essential in our daily lives. PCs, mobile phones, speakers, LEDs, lighting, TVs, and almost every electronic product have a PCB / PCBA inside. Therefore, almost all electronics companies need PCB / PCBA, and other companies also need hardware startup, electronics enthusiasts, manufacturers, etc. Almost any company that mass-produces electronic products uses some kind of PCB. Even in small quantities, companies may choose PCBs if quality and appearance matter.

By continuing to use the site you agree to our privacy policy Terms and Conditions.

Recruit global agents and distributors Join us