From smart phones to kitchen appliances, electronic products play an important role in our daily work. The core of every electronic product is the printed circuit board (PCB). It is the foundation of most electronic products today. These components have a large number of configurations that allow them to provide a variety of functions. With the expansion and development of electronic products in various industries, PCB applications are also developing. Nowadays, the use of PCB board covers almost every industry, and it has developed into a new industry and application. PCB use is the main function center of most electronic products in the modern world. The circuit board connects the components with each other through a series of related circuits.

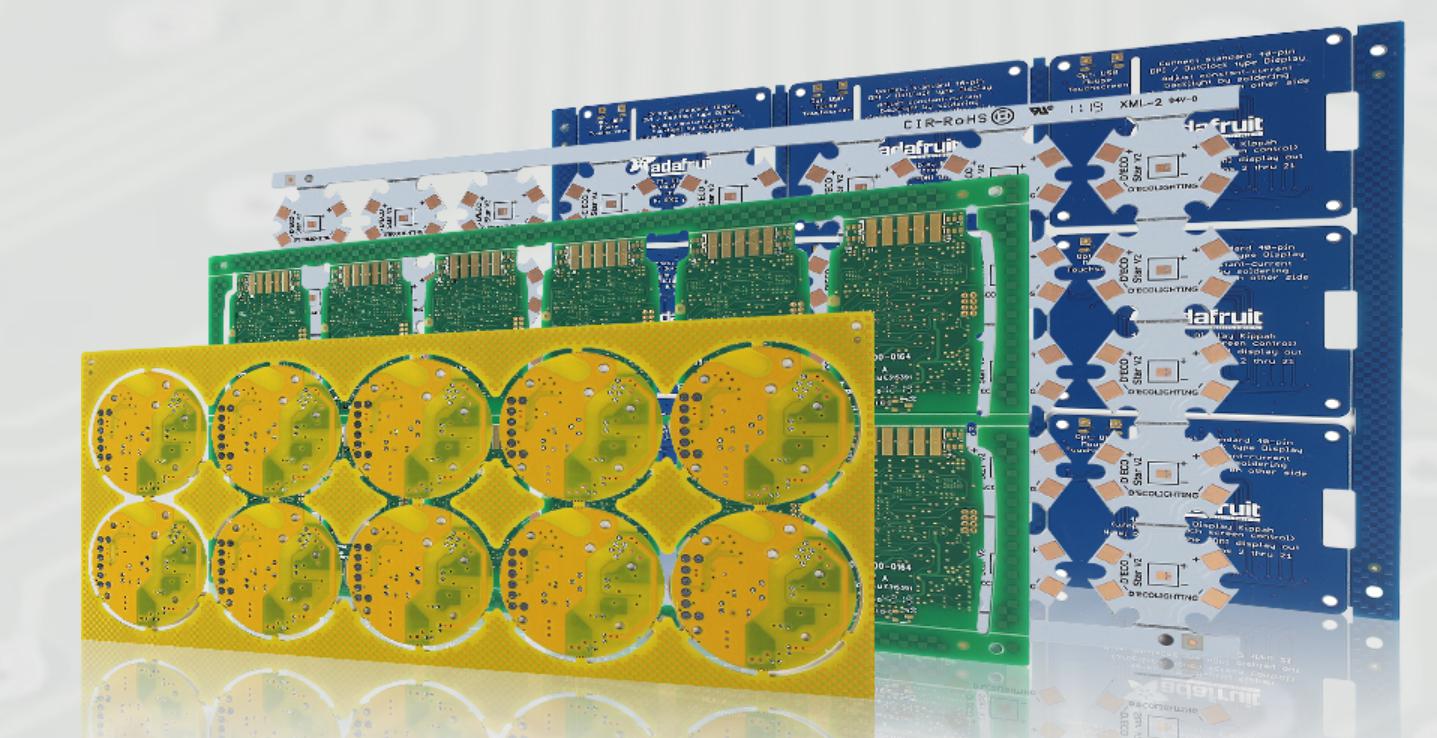

Most people recognize printed circuit boards when they see them. You will find that these small green chips-custom PCB boards are the core of electronic products. PCB is made of numerous configurations and materials. This flexibility enables PCB to play a role in a variety of capacities and applications. We discussed some of these applications in more detail below.

Medical equipment

Electronics make a significant contribution to health - the nursing industry, as diagnostic, monitoring and treatment equipment. With the development of electronic products becoming more efficient and intensive, the medical application of these electronic devices is growing, which brings endless new possibilities.

The core of these medical devices is PCB. PCB in medical industry is highly specialized to adapt to the unique limitations of medical equipment. In many medical applications, small packages are required to meet the size requirements of implants or emergency room monitors. Therefore, medical PCB is often a special high-density interconnect PCB, also known as HDI PCB. Medical PCB can also be made of flexible substrate, so that PCB can be bent in the use process, which is essential for internal and external medical equipment.

Because of the health problems associated with them, medical PCB maintains a higher standard than most other PCB types. In addition to complying with strict medical regulations, repeatability and reliability are two basic qualities that medical PCB suppliers must achieve.

Medical PCB applications are growing as fast as the medical device industry itself. Some of the most common medical PCB applications include:

• monitors: personal and healthcare monitors, including blood glucose monitors, heart rate and blood pressure monitors, etc.

• scanning technology: CT scanners and ultrasonic technology usually use PCB based electronic devices.

• control system: the equipment controls infusion, and the flow rate and distribution are electronically controlled.

• internal devices: pacemakers and similar internal medical devices keep patients healthy and are operated by a micro PCB in the center.

• scientific instruments: medical research uses a large number of scientific instruments to study diseases and test the results of patients. It includes electron microscope, photometer, generator and compressor control system, etc.

Consumer electronics

Consumer electronics are devices we use in daily life, such as smartphones or computers. Even the latest models of refrigerators often contain electronic components. Each of these devices is a PCB.

Due to the large amount of manufacturing of these consumer electronic products, the number of PCBs produced to control them must be equal. These large quantities of PCB have lower unit cost, which makes the price of the final product relatively small. The challenge is to maintain the uniformity and quality of these PCBs, which is why PCB manufacturers must comply with strict industry standards and quality control measures to ensure that each consumer's electronic functions meet expectations.

PCB is widely used in consumer electronic products. The following are some common uses of PCBs in consumer electronics:

Mobile devices: smartphones and tablets are the core of our daily work, our GPS alarm clock.

• computer electronics: the core of desktops and laptops includes PCBs, as do screens and peripherals associated with them.

• recording devices: cameras, digital cameras, microphones and other recording devices all rely on their internal PCB for operation.

• entertainment system: everything in the home entertainment system, from DVD players and video game consoles to TV and audio devices.

Home appliances: almost all modern devices operate with electronic components: alarm clock, microwave, refrigerator, coffee machine, etc

Industrial applications

High power industrial application of PCB is very common. These electronic components control the mechanisms used in factories and manufacturing facilities and must withstand the harsh conditions common in industrial installations. This could include anything, including irritating chemicals, vibrating machinery and rough handling.

In such a rapidly challenging environment, industry standards are equally stringent. At present, thick copper PCB (much thicker than standard ounce PCB) is often seen in other applications. This PCB is useful for high current industrial applications and battery chargers.

• industrial equipment: many electric drills and presses used in the manufacturing industry operate using PCB controlled electronic equipment.

• measuring equipment: equipment used to measure and control pressure, temperature and other variables in the industrial manufacturing process.

Power equipment: DC-AC power inverter, solar Cogeneration Equipment and other power control equipment.

Automotive Applications

Cars are increasingly dependent on electronic components of modern times. Although in the past electronic circuits were actually only used for headlamp switches and windshield wipers, modern cars use electronic devices for more purposes.

Today's automobiles use the developing electronic circuit technology to bring PCBs into some new applications. PCB with high frequency signal such as RF, microwave or millimeter wave frequency is usually used in the common sensor applications in automobiles. In fact, once degraded to military vehicles, radar technology is now very common in modern vehicles, which can help vehicles avoid collisions, monitor blind spots, and adapt to traffic conditions when vehicles are under cruise control.

These advanced systems provide better road safety and improved driving experience, which is why they are so popular in today's motor vehicles. Therefore, manufacturers of these systems must purchase and use more advanced high frequency printed circuit boards and related materials.

Some common applications of PCB in automobile include:

• perimeter monitors: newer car models are often designed with a number of safety systems to help drivers monitor blind spots and determine distances more accurately. Many cars are now equipped with surround monitoring systems that use radar or cameras to measure distances and alert drivers to close objects. These systems need high quality PCB to work properly.

• control system: vehicle control system, including engine management system, fuel regulator and power supply, electronic products using PCB based monitoring and resource management. Some control systems even drive cars for drivers in some cases. For example, some cars on the market now offer automatic parallel parking.

• navigation equipment: existing navigation equipment is very common in modern vehicles, and GPS computers are used to help drivers find their way in unfamiliar areas or determine the fastest route to their destination.

• audio and video equipment: many cars on the market today have state-of-the-art dashboards that connect the vehicle to a radio or a passenger's phone or music device. In addition, many family vehicles use passenger movie screens to occupy passengers during long rides. All of these devices are controlled using PCB based electronics.

In any of these Automotive PCB Applications, specific design issues must be considered. For example, the high vibration environment of a car may impose a lot of strain on a standard rigid PCB. Therefore, many automotive electronics manufacturers do not use rigid PCB, but use flexible PCB. In addition to being small and light, it also has stronger vibration resistance. Therefore, the challenge lies in manufacturing enough high frequency, flexible PCB to meet the needs of large-scale automobile industry.

Aerospace Applications

Like automotive applications, PCB Applications in aerospace require high precision and durability. Jet aircraft and rockets often experience a lot of turbulence in the atmosphere, which means that ordinary rigid PCB may bear enough pressure and be damaged in the process. To solve this problem, most Aerospace manufacturers use flexible PCB, which is not only resistant to vibration damage, but also light and small.

In addition to durability, aerospace PCBs must be very high - functional and precise, making the best function to avoid technical problems. Because the electronic equipment used in aerospace technology is very important for the safety of vehicles and their staff, their perfect operation is very important.

Some common aerospace applications of PCB include:

• monitoring equipment: instruments, including accelerometers, pressure sensors, microphones and torque and force sensors all use PCB as part of their basic functions. These products are used in the engine and cockpit of aircraft and rocket to monitor vehicle functions and communicate with ground control system.

• test equipment: in addition to its function as an aircraft, PCBs are involved in the development and testing of aircraft. PCB is used as the core of the test equipment to collect data during structure, vibration and flight test. These data can be used to develop more efficient, efficient and safer aircraft.

Lighting applications

Printed circuit boards provide a universal base for a variety of high output LED applications. LED lighting solutions are developing rapidly in all walks of life. Its low power consumption, high efficiency and impressive light output are very important. When integrated with PCB, these LEDs get more functions. PCBs help to extend the use of LED lighting solutions, especially including displays and indicators.

Lighting applications

Printed circuit boards provide a universal base for a variety of high output LED applications. LED lighting solutions are developing rapidly in all walks of life. Its low power consumption, high efficiency and impressive light output are very important. When integrated with PCB, these LEDs get more functions. PCBs help to extend the use of LED lighting solutions, especially including displays and indicators.

Some of the most common applications of PCB in the lighting industry led include the following:

• telecommunication industry: telecommunication equipment usually uses PCB to control its LED indicator and display screen. In this industry, light and durable PCB is often advantageous, mainly because of the mechanical density in the industry. Aluminum PCB has better heat transfer performance than FR4, so it can be used in telecommunication lighting applications.

• automotive industry: PCB LED displays are common in the automotive industry, especially dashboard indicators, headlights, brake lights and advanced panel displays. PCB LEDs are particularly popular in the industry because of their low manufacturing cost and impressive durability, which improves the value and service life of vehicles.

• computer technology industry: PCB based LEDs are becoming more and more common in the computer technology industry, commonly used in desktop and laptop displays and indicators. Due to the thermal sensitivity of computer technology, aluminum based PCB is particularly suitable for LED lighting applications in computers.

• medical industry: lighting tools are very important in medical applications, especially in surgical and emergency applications, where high light can help improve the visibility of doctors. In these applications, LED is often the preferred lighting method for its power and small size. PCB is often used as the basis of these applications, especially aluminum pcb. Compared with other PCB types, it has longer service life and better heat transfer capability. In this way, PCB LED can ensure the durable medical devices that can be reused in various medical environments.

• residential and store applications: in addition to the uses listed above, PCB LEDs are becoming more and more popular in homes and businesses in the form of signs and displays. Smart LED lighting is a cheap way for homeowners to effectively light up their homes, while customizable LED displays can guide business to the store.

Although LED is very useful in all kinds of applications, but led is often sensitive to temperature. With the increase of the average temperature of lamps, the life of LED bulb gradually decreases. Although many traditional PCBs provide excellent functions, not all PCBs are suitable for LED applications. When paired with LEDs, some PCBs may not transfer heat fast enough to provide a stable temperature environment for the LEDs to work at maximum efficiency. In order to give full play to the best performance in lighting applications, PCB designed for LED must be designed to maximize the heat transfer capability.

For this reason, aluminum backed PCB is the perfect solution. Most high lumen output LED applications use aluminum back PCB, which is mainly used for higher level of heat transfer that aluminum PCB can achieve. In this way, PCB does not need additional radiators in the design, but other radiators can be added to further improve the heat transfer capability of PCB. However, combining the heat sink into the PCB base itself allows manufacturers and end users to achieve a more compact design at a lower cost.

Other applications

PCB based products are used in hundreds of applications in these industries. Some examples include the following:

• gun applications: military and civilian gun manufacturers usually use PCB in their test equipment. Before putting these products on the market, manufacturers usually use such equipment to ensure the safety and functionality of explosives, guns and ammunition. Some of the equipment used include penetration impact recorder and impact test equipment.

• marine applications: underwater and marine applications are common places to find PCB. PCB usually controls navigation, engine management and power distribution systems used on sailboats. Due to the fluctuation of pressure and vibration, designers must consider various factors to ensure normal and continuous function.

• security applications: security systems inside and outside the home and business use PCBs to coordinate the various components and signals used to detect the presence of intruders. PCB is used for smoke, fire and anti-theft alarms, as are electronic door locks and motion sensors.

• broadcast and telecommunications applications: as mentioned earlier, PCB based LED lighting displays are common in the telecommunications and broadcasting industries. PCB is also suitable for various other functions in this industry. High frequency amplifier and filter equipment usually use PCB, booster station, receiver, frequency board, hybrid deck and microphone.

By continuing to use the site you agree to our privacy policy Terms and Conditions.

Recruit global agents and distributors Join us