When it comes to PCB board manufacturing, every detail matters. One of the most crucial aspects is the board thickness tolerance. Why does this matter? Because even a slight deviation can have significant implications on the performance and reliability of your circuit board. In this blog post, we will explore the importance of PCB board thickness tolerance and why it should not be overlooked. We will delve into the different types of tolerances that are involved in PCB fabrication, including copper width and spacing tolerances, multilayer board thickness tolerance, PCB drilling tolerances, routing tolerances, controlled impedance tolerances, and solder mask feature tolerances. By understanding these tolerances and meeting PCB specification requirements, you can ensure that your circuit boards are reliable and perform optimally. We will also cover the turnaround time for PCB orders so that you can plan accordingly and meet your project deadlines without compromising on quality.

The importance of PCB board thickness tolerance lies in maintaining consistent and reliable performance. If the board thickness varies outside of the tolerance range, it can lead to issues during assembly and functionality. Accurate thickness tolerance ensures proper fit and reduces the risk of damage, while meeting industry standards can enhance customer satisfaction and trust in the product.

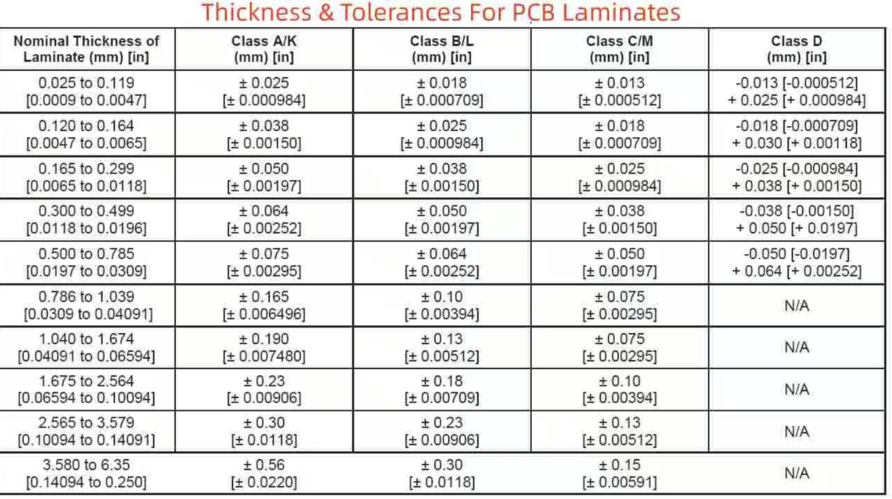

Meeting industry standards for PCB fabrication tolerances ensures consistent and reliable performance of electronic devices. The PCB thickness tolerance refers to the allowable deviation in thickness that can cause fitting problems and affect electrical properties. Maintaining desired tolerance during manufacturing is critical for meeting design specifications and device compatibility. Quality control measures such as adhering to valid IPC guidelines should be followed. Miscommunication with suppliers regarding smaller tolerances can result in difficulties meeting ultra-demanding applications. Expert consultations can help meet even the most complex design challenges.

Maintaining accurate copper width and spacing tolerances is crucial for successful PCB board manufacturing. Adhering to valid IPC guidelines and ensuring that the copper width and spacing remain within the desired tolerance range will prevent signal distortion, overheating, or short circuits in ultra-demanding applications. Suppliers should be consulted for feasibility on smaller tolerances. Miscommunication during the layout process can lead to errors in copper weight, annular ring, or finished hole size. By following proper parameters for hole size, pad size, v-cut, and plating thicknesses, it is possible to satisfy even the most complex design challenges while maintaining component overages.

Proper maintenance of thickness tolerance is critical for multilayer printed circuit boards (PCBs). Deviation in the board's total thickness may lead to problems with signal interference and heat dissipation ultimately affecting the device's overall performance. The manufacturer must adhere to strict guidelines and maintain proper control over factors such as the number of layers and copper weight while producing multilayer PCBs. In-house guidelines related to board fabrication tolerances should be considered when designing a multilayer circuit board layout. Meeting design specification becomes vital; hence a copy of IPC Guidelines is useful for feasibility consultations.

Properly controlling PCB drilling tolerances is crucial in manufacturing high-quality printed circuit boards (PCBs). Along with copper width and spacing tolerances and multilayer board thickness tolerance, it affects the performance of components and overall functionality of the device. With smaller tolerances becoming necessary for ultra-demanding applications, adhering to valid IPC guidelines, or in-house tolerance guidelines become imperative for PCB manufacturers. By ensuring that boards meet all parameters like finished hole size, pad size, and annular ring, they can meet even the most complex design challenges.

Maintaining consistent routing tolerances is essential in PCB manufacturing to ensure that electronic devices function properly. Deviations from specified thickness tolerance can cause issues like warping or delamination. Keeping accurate circuit board assembly and performance requires adherence to industry standards and specifications. By maintaining consistent routing tolerances in all aspects of PCB design and manufacture-from layout processes through consultations-you'll avoid miscommunications that could derail even the most complex design challenges. Achieving tighter tolerances not only ensures high-heat performance but also helps strengthen supplier relationships while reducing component overages.

Proper controlled impedance tolerances in PCB design are critical for ensuring the optimum functionality and reliability of electronic devices. Deviations from the specified thickness can cause signal integrity issues that could significantly impact overall performance. Moreover, it is equally important to ensure perfect compatibility with other components and manufacturing processes to guarantee seamless integration and efficiency. Adherence to industry standards and specifications is vital for maintaining consistent quality throughout the manufacturing process.

Properly maintaining solder mask feature tolerances is critical during PCB assembly. The specified tolerance must be met since any deviation in thickness could result in warping or even complete failure of the circuit board. Ensuring proper thickness tolerance guarantees that components fit correctly and that the board performs as expected while improving manufacturing consistency and yield rates.

Achieving the required specifications for a printed circuit board (PCB) depends on many factors but none more important than proper PCB board thickness tolerance. Deviations in thickness can negatively affect functionality and performance. Selecting an experienced PCB manufacturer knowledgeable in IPC guidelines and in-house tolerance guidelines helps ensure compliance with industry standards. Avoid complications due to miscommunication or incorrect information by sending along a copy of your required tolerances when consulting with your supplier. With their expertise in handling even the most complex design challenges for various types of boards including high-heat HDI boards for ultra-demanding applications, you can trust them to manufacture PCBS that exceed your expectations.

For ultra-demanding applications, adherence to proper PCB board thickness tolerance parameters is critical for ensuring performance and reliability. Choosing a reliable manufacturer with in-house tolerance guidelines ensures accurate tolerances within acceptable ranges, reducing turnaround time while meeting industry standards/regulatory requirements. Communication breakdowns or disregarding IPC guidelines may jeopardize manufactured PCBs' functionality. A designer must obtain a copy of the board thickness tolerance requirements from their chosen supplier before commencing work and should factor this parameter into component sourcing/overages while considering feasibility.

In conclusion, PCB board thickness tolerance is a critical factor in creating quality PCBs. It plays a crucial role in ensuring that the final product meets the required specifications and standards. Any deviation from the specified tolerances can cause significant issues such as misalignments, short circuits, and signal interference. It is essential to work with an experienced and reliable PCB manufacturer who understands the importance of maintaining strict tolerances throughout the fabrication process. This will ensure that your PCBs meet or exceed the required specifications for your project. Need a reliable PCB manufacturer? Contact us today to discuss your requirements and get started on your project.

By continuing to use the site you agree to our privacy policy Terms and Conditions.

Recruit global agents and distributors Join us