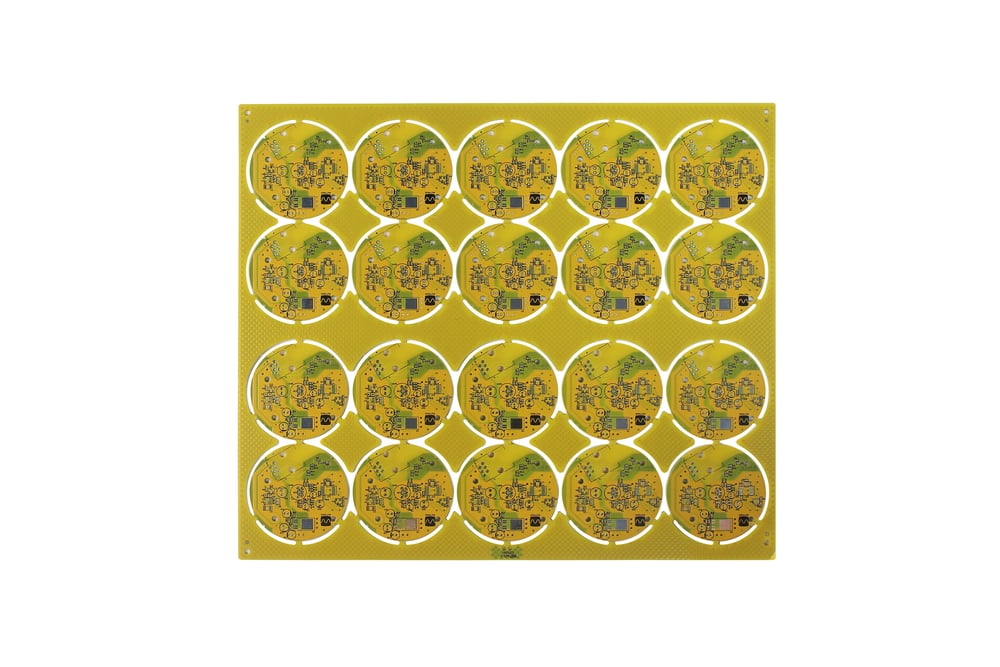

PCB fabrication uses different materials, and FR-4 PCBs are specifically made with FR4 manufacturing material. The special thing about these is that they are made with a fiberglass epoxy laminate fire retardant material. This unique characteristic makes these applicable for several applications as they efficiently operate with temperatures ranging up to 130 degrees Celsius.

Although the major properties of FR-4 PCBs remain the same for all types, there are some differences in their working, as discussed below.

The single-side PCBs made with FR4 material work by having copper foil on one side. So, the components of the circuit are also present on that side. On the other side, there is nothing but the epoxy rose, which makes these very affordable.

With copper foil on one side, all the connections and paths of the current's flow are on one side. Not only is their working future proof but manufacturing is also simple because of the simplicity that keeps these from getting expensive even with technological advancements.

The double-side FR-4 PCBs work by having their copper foil on one side, but the components are present on both sides. It is because these PCBs have circuit path traces on both sides. Apart from them, everything about their working and manufacturing is the same as single-sided PCBs because these are also made with epoxy risen.

The only difference in their working is having components soldered on both sides. Due to this difference, the traces of the circuit's path often cross with ones on the other side.

Multi-layer FR4 PCB is usually made with 3 conduction layers instead of one or two. The core material of these PCBs is laminated under high temperature and pressure environments for making the multi-layer PCB. It works with multiple layers of conductive paths, but there are only 2 main sides of these PCBs, so the circuit components are soldered on both sides.

Another type of FR4 PCB is rigid PCCB, which has only the FR4 material used for manufacturing. No other materials are used for their making, so these work like regular rigid PCBs. A rigid structure makes these a good choice for normal applications with no flexibility requirements. The special thing about these PCBs is that they perform well under high temperatures.

The rigid-flex FR4 PCB works with a flexible circuit that is also resistant to heat. Some applications require the PCB to work under high temperatures while having flexibility, and these PCBs make a perfect choice for such applications. The core material is rigid-flex so that it can be soldered and installed at a desired angle according to the application.

With different types having slight differences in their working, you must pick the right one from all FR-4 PCBs. In that way, your device may achieve the best efficiency and reliability.

By continuing to use the site you agree to our privacy policy Terms and Conditions.

Recruit global agents and distributors Join us