PCBs usually have soldering pads on top of which we solder a wire to make a strong connection. Otherwise, there are solder pads with holes so wires or pins can pass through and be soldered to make a joint. However, there is another way a PCB can make a connection with other PCBs, and that is with the help of castellation PCBs.

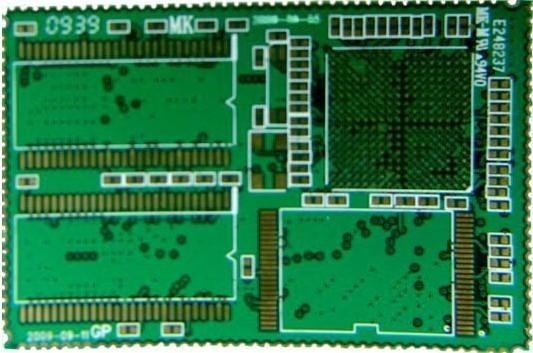

Castellation PCBs are regular PCBs with half holes on their edges, and each hole has a soldering pad on it. So, when you have to solder them, they can connect directly with the base PCB. Below are the top 5 uses of castellation PCBs.

These PCBs are used to easily join 2 circuit boards where modularity is a major concern. For instance, if your PCB needs some modular wireless capabilities, then a separate wireless connectivity module will be designed with castellation design, making it possible to solder it on the main circuit board directly. This soldering process saves more space and time.

When multiple PCBs are joined together, joint integrity is one of the major concerns. Using a castellation PCB resolves all worries about the strength of the joint because a blob of solder joins every solder pad of the circuit board below and on the top. In this way, the solder joints can be stronger than any other mode of connection like:

· Wires

· Flexible PCB

· Gold pin contact with the slot

If you want to save space in your application, choosing castellation PCB will be the right choice, considering how these remove wires between 2 PCBs. Each PCB is a few millimeters thick, and the overall thickness does not increase significantly. It makes a great choice for compact devices that need multiple PCBs working in them.

One of the best uses of these PCBs is their easy repair and troubleshooting. Say that your device has this PCB connection that provides Bluetooth capability. If the Bluetooth feature stops working, troubleshooting and repairing will simply mean replacing the previous PCB with a new one. This will make it extremely easy to tell where the issue lies.

Going with these PCBs helps reduce the overall product cost because fewer components are needed. If you have multiple PCBs working together, you may need to transmit a signal between them that needs to add an encoder and decoder for certain applications.

Other components involve wires. With a castellation PCB, all these components are not needed because of the direct connection.

Castellation PCBs remove the need for wires or pins to combine different PCBs. It not only saves space but also saves cost with another benefit. So, consider using these for reliability if you are working with a PCB.

By continuing to use the site you agree to our privacy policy Terms and Conditions.

Recruit global agents and distributors Join us