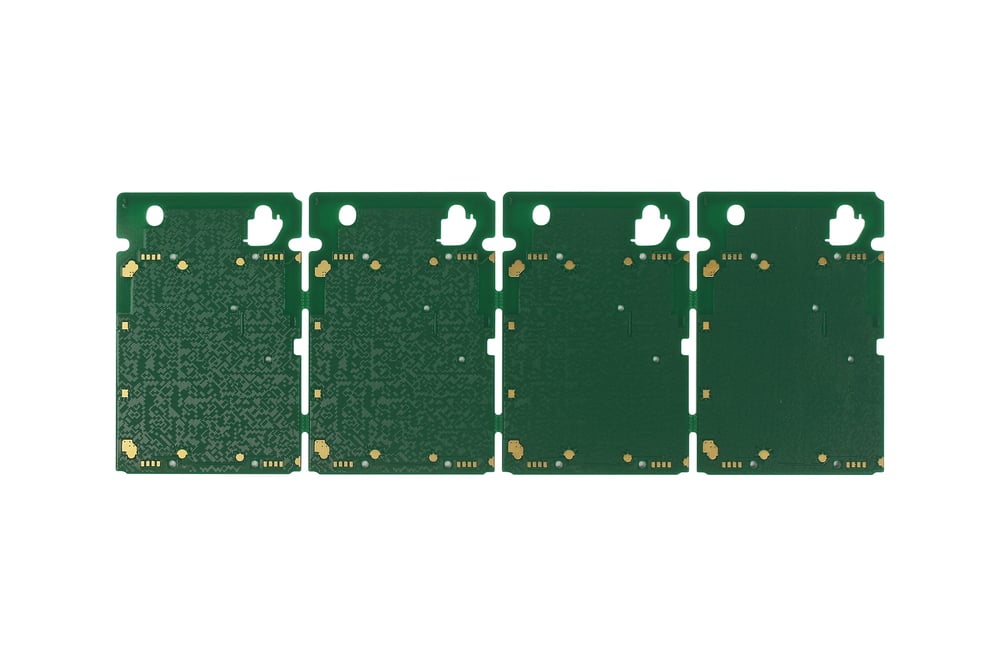

Certain PCB applications require coils to complete the circuit and its functionality. The traditional and more common way of adding coil on a PCB is by soldering one like other components. However, now you can get coil PCBs with built-in coils in them.

The following are the top 5 benefits of coil PCBs you need to know about.

When you need a coil on a PCB, you have the choice to use the wire coil or the copper trace coil built into the PCB. The benefit of going with coil PCB is that it is efficient with self-capacitance. When you use a wire coil with the same specifications, it would be inefficient because of the capacitance among adjacent tracks depending on the thickness of the copper wire and the separation among the wire.

With the coil PCB, that is not the case, and the self-capacitance is smaller, resulting in better value integrity.

If you want to place the PCB in a tighter space, you may not have enough room for a vertically standing coil. In most cases, horizontal space is available, and there is a lack of height in devices. In those cases, coil PCB removes the need to solder a coil on the PCB itself. So, not only does manufacturing becomes easier, but it also becomes cheaper because:

· You don’t need additional components.

· Creating a copper trace coil on the PCB does not require additional design, procedure, or equipment.

One of the biggest problems with using coils in circuits is that thicknesses, diameters, and wire quality differs among coils. For instance, if you are working on a huge batch of PCBs and getting coils from multiple sources, the output value from the circuit may not remain the same.

On the other hand, etching coils into the copper trace on a PCB makes it possible to achieve signal integrity from the whole batch of PCBs.

Fitting huge coils in smaller places becomes possible with coil PCBs because these do not take up a lot of thickness on the PCB. Things get even better when you use multilayer or double-sided PCB because other components get soldered on the back side of the coil if they do not change their input and output values.

Working with coil PCB means you can change the diameter of the coil's trace to change the inductance and Q factor of the coil to get the right capacitance from your coil. While you design, it can be set up, and there will be no need to worry about the wire's diameter and other specifications.

Coil PCBs solve many issues regarding a PCB and bring several benefits. However, their selection is crucial as, once manufactured, changing specifications may not be easier. So, when you design your PCB with coils, select its dimensions and capabilities correctly.

By continuing to use the site you agree to our privacy policy Terms and Conditions.

Recruit global agents and distributors Join us