Two layers of conductive material and an insulating layer make up what is known as a two-layer PCB (Printed Circuit Board). A two-layer printed circuit board's thickness might change based on its material, manufacturing method, and application.

Two-layer printed circuit boards (PCBs) come in a range of thicknesses depending on the materials used in their construction. Fiberglass and epoxy resin are the most popular choices for PCBs, with copper foil added for conductivity reinforcement.

Copper layers can be anything from half an ounce to four ounces in thickness, with the higher conductivity and longer lifespan coming from the thicker layers. It's up to the manufacturer and the intended use of the board to choose how thick the fiberglass or epoxy resin layer should be.

The thickness of a two-layer PCB can also be affected by the manufacturing process used to create it. Etching is the standard method for making printed circuit boards, in which copper foil is placed on a substrate and then chemically etched away in specific areas.

Certain etching methods can create thinner copper layers than others, depending on how deep they etch the material. Certain manufacturing procedures can create thinner insulating layers than others, and the manufacturing process also determines the thickness of the insulating layer.

The thickness of a two-layer PCB can also be affected by its intended application. It is possible that the copper and insulating layers of PCBs used in high-performance applications, such as aerospace or military systems, must be thicker.

Printed circuit boards (PCBs) used in consumer electronics and other low-performance applications may not need to be as thick as those used in high-performance applications since they are not subjected to the same strains and demands.

The above factors can affect the normal thickness of a two-layer PCB. Two-layer printed circuit boards can vary in thickness from 0.79 mm to 0.062 inches (0.31 to 15.24 mm) (1.57 mm).

Let us explain the above process in detail.

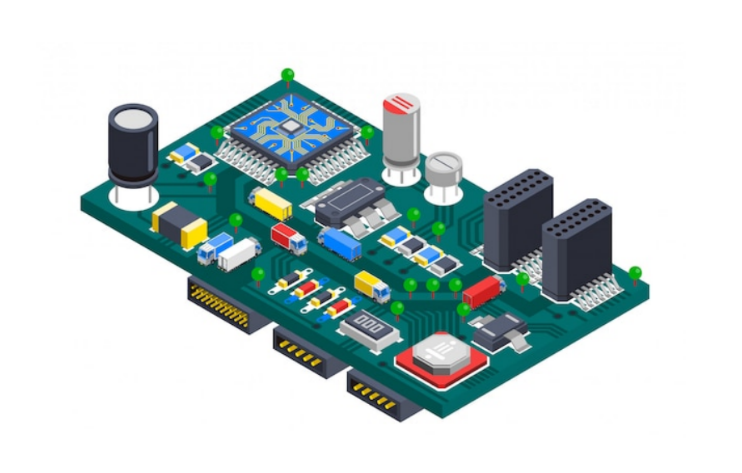

It is necessary to output the data for manufacturing the board from the CAD data that has completed the board design. This data is called Gerber data. At the same time, it outputs a set of various data for manufacturing, such as hole data.

Create various films for substrate manufacturing from Gerber data.

Drill holes for through holes on the board based on the NC data. Drilling is generally used, but recently, with the miniaturization of substrates, laser processing is sometimes used for build-up substrates.

Drilling holes in the printed circuit board is the most time-consuming process, and the cost varies depending on the number of holes. Processing costs can be reduced by increasing the size of the holes or reducing the number of holes.

To electrically connect the front and back copper foil surfaces, vias are formed by copper plating. Apply dry film. After that, a photosensitive resist agent is applied on top of the dry film, exposed and cured, and then the copper plating is removed with the agent.

Then, only the copper plating where the resist was applied remains, and a pattern is formed on the board. Finally, peel off the dry film from the substrate. In the case of a multi-layer board, the insulating layer is crimped on the created board, and the same process is repeated.

If the pattern is exposed on the board, there is no insulating film, so problems such as shorting between copper foils or shorting due to metal chips or solder on the surface will occur.

To prevent defects, an insulating solder mask is applied to the board surface to protect the pattern. Unlike the resist used for patterning in Step 4, the solder mask remains on the board and protects it after board fabrication is complete.

For example, the board is plated with solder (led or lead-free) to improve the solderability of the exposed pattern and prevent the copper foil from rusting.

The board is put into a hot solder bath, and high-temperature, high-pressure hot air is blown to evenly coat the board with solder. Solder is not applied to the resist layer, so solder can be applied only to the component mounting area. In addition to solder plating, electroless gold plating (gold flash) is sometimes used. In the case of flux processing, flux is applied.

To improve functionality, such as symbol marks and logos that serve as guides when mounting components on printed circuit boards, silk printing is used to improve visibility.

After finishing silk printing, we use a router to process the outer shape and the opening according to the outer size of the final product.

After manufacturing the printed circuit board, the board is inspected for defects. There are two processes: checking the open/short circuits of the circuit by applying test pins to the continuity part (continuity test) and checking visually or using an image recognition camera.

High-voltage boards are often used in video processing boards for medical equipment. In this case, the customer requested to manufacture a prototype board for high voltage and test the discharge.

In the past, when checking the discharge due to the potential difference between adjacent through-holes, a build-up board was created each time, and the test was performed by changing the conditions. However, manufacturing a build-up board is costly, and they wanted to reduce costs at the prototype stage.

The specification was to stack two boards and connect them with through-holes for information and communication boards mounted on communication equipment. The upper board uses a communication module.

When stacking two boards, a motherboard, and a child board, there is a risk that the boards will warp and the boards will not adhere to each other, resulting in uneven soldering and communication failure. In this case, the substrate was thin, and warpage was likely to occur during substrate manufacturing.

Due to warping, the solder did not reach the top of the through-hole, leading to troubles such as the communication module not moving, and it was necessary to improve it.

To avoid the risk of communication failures due to warpage, we contacted our company, which has the know-how to consistently handle everything from board design to manufacturing and mounting.

Thick copper substrates (70㎛) have been used in power supply substrates for communication equipment as a countermeasure against large currents. In the case of large currents, it is essential to increase the thickness of the copper foil, but this time, it was necessary to mount the components with a fine pitch.

For fine pitch, it is necessary to reduce the thickness of the copper foil. This is because if the copper foil is thick, there is a risk of disconnection in thin patterns due to over-etching.

No manufacturer could handle the dilemma of thickening the copper foil to handle large currents but thinning the copper foil to support fine pitch. Due to the large current, the thickness of the copper foil could not be reduced.

Please leave it to us to manufacture the printed circuit board! I hope you understand the process of manufacturing printed circuit boards. System Products, which operates analog circuit/substrate manufacturing.com, consistently manufactures analog circuits and substrates.

Please feel free to contact us if you have any problems with manufacturing analog circuits and boards!

By continuing to use the site you agree to our privacy policy Terms and Conditions.

Recruit global agents and distributors Join us