The question can and probably should be asked: “Is it important to understand the PCB fabrication process?” After all, PCB fabrication is not a design activity, it is an outsourced activity that is performed by a contract manufacturer (CM). Although, it is true that fabrication is not a design task, it is done in strict adherence to the specifications that you provide to your CM.

In most cases, your CM is not privy to your design intent or performance objectives. Therefore, they would not be aware of whether you are making good choices for materials, layout, via locations and types, trace parameters or other board factors that set during fabrication and may impact your PCB’s manufacturability, production yield rate or performance after deployment, as listed below:

Manufacturability

The manufacturability of your boards depend on a number of design choices. These include ensuring that adequate clearances exist between surface elements and the board edge and the material selected has a sufficiently high coefficient of thermal expansion (CTE) to withstand PCBA, especially for no-lead soldering. Either of these could result in the inability of your board being built without redesign. Furthermore, if you decide to panelize your designs then that too will require forethought.

Yield rate

Your board can be successfully fabricated, while fabrication issues exist. For example, specifying parameters that stretch the tolerance boundaries of your CM’s equipment can result in higher than acceptable numbers of boards that are unusable.

Reliability

Depending upon your board’s intended usage it is classified according to IPC-6011. For rigid PCBs, there are three classification levels that set specific parameters that your board’s construction must meet to achieve a specified level of performance reliability. Having your board built to meet a lower classification than your application requires will likely result in inconsistent operation or premature board failure.

The examples listed above are not exhaustive but represent the types of problems you may experience if proper fabrication specification decisions are not made during design.

Therefore, the answer is an emphatic yes! It is important that you understand the PCB fabrication process as the design choices you make for this stage can reverberate throughout PCB development, production and even into operation. Your best defense against the types of problems that can result from not incorporating knowledge of the PCB fabrication process into your design decisions is the utilization of design for manufacturing (DFM) rules and guidelines that are based upon the capabilities of your CM.

What Victory can provide

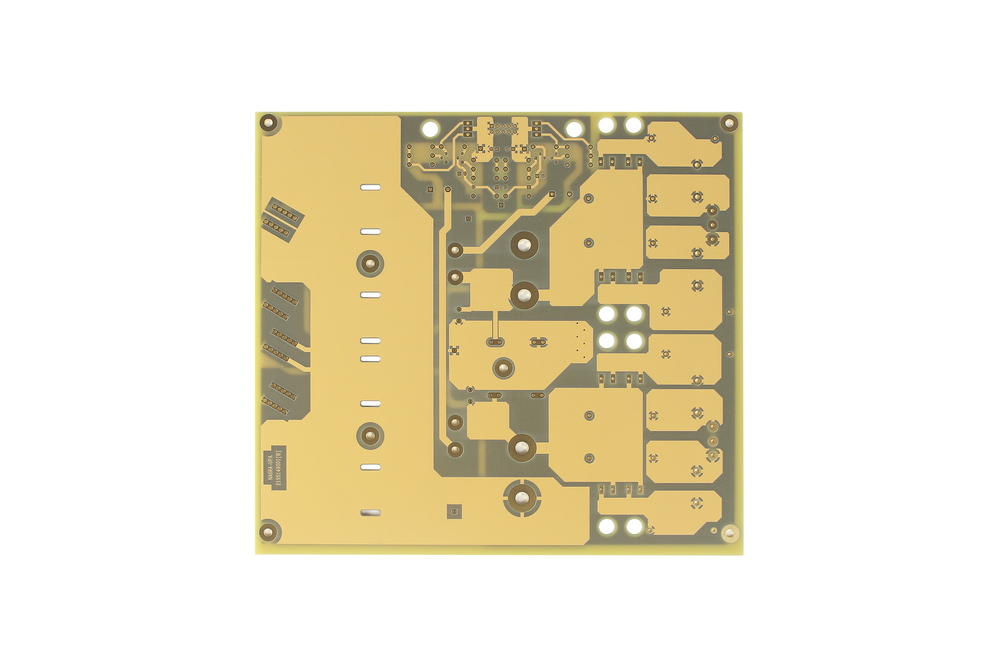

· 4 Layer Yellow Soldermask PCB with 2oz Finished Copper Thickness

· Black 4 Layer Heavy Copper PCB with 6oz Finished Copper Thickness

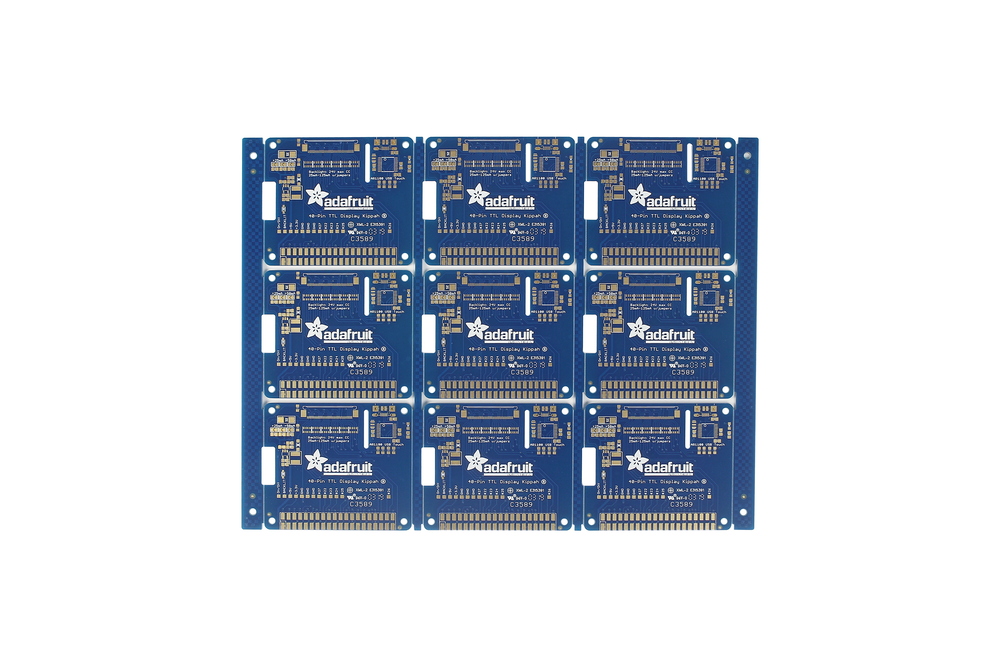

· Blue Soldermask 2 Lay Immersion Gold PCB for Consumer electronics

About us

Victory is a professional PCB manufacturer which established in 2005. Adhere to be a specialized manufacturer for multiply species, small to medium series, and quick turn production, we insist to provide 3H(high quality, high precision and high density) PCBs for our customers. If you are looking for a reliable merchandise of PCB Fabrication, please contact us now!

By continuing to use the site you agree to our privacy policy Terms and Conditions.

Recruit global agents and distributors Join us