Multilayer printed circuit boards (PCBs) are intricate electronic circuits composed of numerous layers of conductive pathways and insulating substrates. They find application in diverse electronic devices ranging from consumer goods to aerospace systems.

This development has been driven by the numerous benefits that multilayer printed circuit boards offer. The present article offers a thorough exposition on the design of multilayer printed circuit boards (PCBs), encompassing fundamental aspects of the manufacturing process as well as sophisticated design techniques.

Multilayer printed circuit boards are intricate electronic circuits composed of numerous layers of conductive pathways and insulating substrates. They find application in diverse electronic devices ranging from consumer goods to aerospace systems. The following segment offers an all-encompassing manual for the process of fabricating multilayer PCBs.

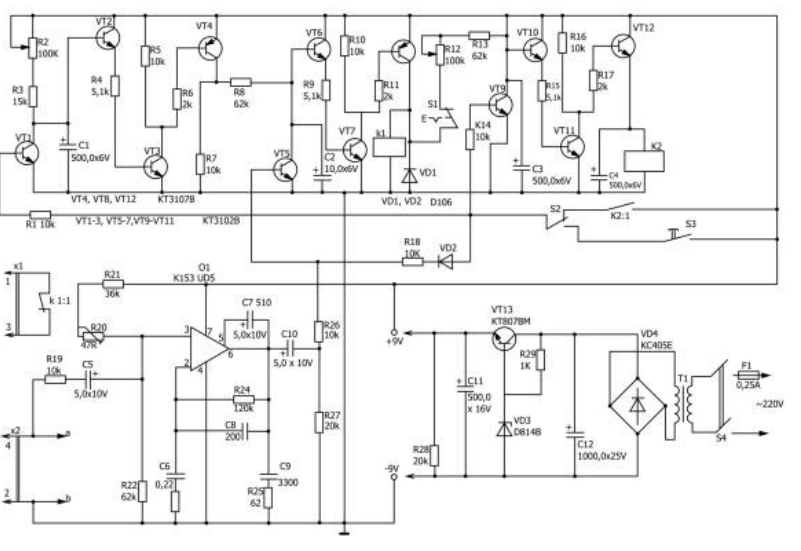

The initial stage of the multilayer printed circuit board (PCB) production process involves the establishment of a layer stack, which outlines the quantity and configuration of layers present on the PCB.

The stratification arrangement plays a pivotal role in ascertaining the ultimate performance of the printed circuit board.

The selection of materials for individual layers is a crucial aspect that significantly impacts the operational efficiency of the ultimate printed circuit board. Copper-clad laminates, prepregs, and solder masks are the prevalent materials utilised in the production of multilayer printed circuit boards.

Copper-clad laminates are utilised as the conductive layers in conjunction with prepreg, which serves as an insulating material to separate the layers from one another. The application of a solder mask onto a printed circuit board serves to safeguard it against external elements, including but not limited to moisture and dust.

Subsequent to the placement of the layer and identification of the materials, the subsequent stage in the manufacturing process involves perforating the necessary apertures in the printed circuit board. The apertures facilitate interconnection between the various layers of the printed circuit board and afford ingress to the constituent modules. Computer-controlled drilling machines are commonly utilised for drilling holes.

Subsequent to perforating the apertures, the subsequent measure involves envisioning the conductive strata of the printed circuit board. The process involves the application of a conductive pattern onto a copper clad laminate through printing. Typically, photoresist and photolithography techniques are employed in the production of conductor traces.

Subsequent to the formation of conductive pathways on the copper-clad laminate, the subsequent stage involves the application of a copper coating onto the aforementioned pathways. The process involves immersing the printed circuit board (PCB) into a plating solution, resulting in the deposition of a slender copper coating onto the conductive pathways.

Subsequent to the application of the conductive layers, the subsequent stage involves the lamination of said layers through the utilisation of prepregs. The stacking of layers is followed by the insertion of a prepreg between each layer. Subsequently, the stack is positioned onto a laminating press, wherein the layers are fused together through the application of heat and pressure.

Subsequent to the lamination of the layers, the subsequent stage involves the elimination of superfluous copper with the aim of producing the ultimate conductive traces. The process involves the application of an acid onto the printed circuit board, which facilitates the dissolution of excess copper.

The ultimate stage of the fabrication process entails surface treatment, whereby a safeguarding layer is administered onto the printed circuit board. The plating may take the form of a solder mask or a surface finish, such as gold or silver. The application of the surface finish is executed through the process of screen printing, which encompasses the utilisation of stencil coating.

The stratification process plays a pivotal role in influencing the efficacy of the ultimate multilayer printed circuit board. The layer stack is a crucial aspect of a printed circuit board (PCB) as it specifies the quantity and configuration of layers, the dimensions of each layer, and the composition of materials employed for each layer.

The process of layer stacking necessitates careful consideration of PCB specifications, including but not limited to signal integrity, power distribution, and thermal management.

In the second section, the topic of discussion is centred on power and ground planes. Multilayer printed circuit boards necessitate the presence of power and ground planes.

The power layers serve the purpose of furnishing a consistent voltage source for the components present on the printed circuit board, whereas the ground layers are responsible for providing a low impedance current return path throughout the PCB.

The strategic arrangement and configuration of the power and ground planes necessitate meticulous deliberation to mitigate the impact of noise and interference on the printed circuit board.

The consideration of signal integrity holds significant importance in the design of multilayer printed circuit boards.

The thermal management of multi-layer printed circuit boards is a critical aspect that can impact the operational efficiency and dependability of the circuit board.

The thermal management of a multi-layer printed circuit board necessitates the incorporation of techniques to regulate the heat generated by the components on the board. These techniques may include the utilisation of heatsinks, thermal pads, and other similar measures.

The strategic arrangement of constituents on a multi-layer Printed Circuit Board (PCB) necessitates meticulous deliberation to enhance the efficiency and dependability of the PCB. The arrangement of components on a printed circuit board has the potential to impact various aspects of its performance, including signal integrity, thermal management, and power distribution.

In the design of a multi-layer printed circuit board (PCB), it is advisable to undertake measures aimed at minimising the distance between components and shortening the length of signal paths.

The optimisation of performance and reliability of a printed circuit board with multiple layers requires meticulous design of its routing.

The routing of printed circuit boards has an impact on various aspects such as signal integrity, power distribution, and thermal management of the PCB.

The development of a multi-layer printed circuit board necessitates the implementation of strategies aimed at minimising the length of signal tracks, decreasing the number of lanes, and optimising high-speed signal routing.

Ensuring adherence to electromagnetic compatibility (EMC) and electromagnetic interference (EMI) regulations is a crucial aspect of multi-layer printed circuit board design.

The compliance standards for Electromagnetic Compatibility (EMC) and Electromagnetic Interference (EMI) are in place to guarantee that electronic devices function without interference and with dependable performance in their designated surroundings.

The development of a multilayer printed circuit board necessitates the incorporation of strategies aimed at mitigating the emanation of electromagnetic radiation and susceptibility to external interference.

The manufacturing process of a multi-layer printed circuit board necessitates careful consideration of the capabilities and limitations of the printed circuit board manufacturer.

Strategies for enhancing the efficiency of multilayer printed circuit boards.

Methods for Routing at High Speeds The implementation of high-speed routing techniques guarantees the efficient transmission of signals among various components of a printed circuit board while minimising the occurrence of distortion and interference. The aforementioned techniques encompass:

Differential pair routing pertains to the transmission of high-speed signals between two pathways that exhibit equal and opposite signal voltages. The implementation of this particular methodology results in a decrease in the occurrence of crosstalk and electromagnetic interference (EMI) within the signal.

Length negotiation is a process that guarantees the uniformity of track lengths that carry high-speed signals. The implementation of this technique results in a decrease in signal distortion and an enhancement in signal integrity.

The technique of via seam entails the arrangement of multiple vias in close proximity to each other, resulting in the formation of a contiguous ground plane. The implementation of this technique results in a decrease in unwanted sound and enhances the reliability of the signal.

Thermal management methodologies are employed to guarantee that the temperature of the printed circuit board stays within acceptable thresholds. The aforementioned techniques encompass:

Radiators are devices that are used for heating a room or a building. Heatsinks are employed for the purpose of thermal management, specifically to facilitate the dissipation of heat that is generated by the various components present on a printed circuit board (PCB).

Typically, these components are fabricated from either aluminium or copper and affixed to the printed circuit board (PCB) through the utilisation of thermal paste or thermal tape.

Thermal seams facilitate the transfer of heat from the uppermost layer of the printed circuit board (PCB) to its lowermost layer. Typically, they are positioned in close proximity to heat-generating components.

Copper Leakage pertains to the practise of populating unutilized regions of the Printed Circuit Board (PCB) with copper. This approach facilitates the dispersion of thermal energy throughout the printed circuit board (PCB), resulting in a reduction of its temperature.

The implementation of power distribution techniques is aimed at minimising power losses during the supply of power to various components on a printed circuit board. The aforementioned techniques encompass:

Power planes are utilised to disseminate power throughout the printed circuit board (PCB). Typically situated on the internal layers of the printed circuit board, these elements can be linked to components through the use of leads.

The topic of discussion pertains to decoupling capacitors. Decoupling capacitors serve to mitigate high frequency noise originating from the power supply. Typically, they are positioned in close proximity to elements that necessitate consistent power supply.

The process of power integrity analysis entails the creation of a model that characterises the performance of a power distribution network with the aim of detecting possible issues such as voltage dips.

The implementation of Design for Manufacturability (DFM) methodologies guarantees the efficient and low-defect manufacturing of the Printed Circuit Board (PCB). The aforementioned methods encompass:

Panelization is a process that optimises manufacturing efficiency by arranging multiple printed circuit boards (PCBs) on a larger panel.

The selection of the minimum trace width and spacing should be made in a manner that guarantees the manufacturability of the printed circuit board (PCB) utilising the chosen fabrication process.

The Design Rule Check (DRC) is a process that involves the utilisation of automated checks on a design to verify its compliance with the fabrication process requirements.

In conclusion, the implementation of these techniques can enhance the operational efficiency of multilayer PCBs, as per the perspective of designers. The implementation of high-speed routing techniques has been observed to enhance signal integrity, while the utilisation of thermal management techniques has been noted to be effective in regulating temperature. Decrease the temperature of the object.

By continuing to use the site you agree to our privacy policy Terms and Conditions.

Recruit global agents and distributors Join us