PCB stack-up design has many constraints. High-speed designs need interplane capacitance, regulated impedance, and crosstalk minimization. High-speed printed circuit boards now consider trace impedance, although stack-up affects crosstalk susceptibility and sheet capacitance between ground and power planes.

Many of these concerns can be worked out manually or with a circuit design programme to model the impedance in your board. Still, the best PCB design tools offer more complex methods of designing for regulated impedance.

Altium Designer's stack-up design process includes PCB impedance calculations, eliminating the need for web calculators. Altium Designer's layer stack management and routing features include a field solver for board-wide impedance adjustment. Altium Designer's Layer Stack Manager and routing tools provide a smooth PCB impedance calculator for high-speed designs.

The geometry of the traces, PCB core or prepreg material, and layer orientation affect your PCB's impedance. Design tools must account for the impedance values of edge-coupled, embedded, and offset trace layouts. Modelling copper roughness and dispersion could improve these tools.

Online PCB calculators and analytical calculations cannot account for roughness, dispersion, or etching.

PCB design parameters are defined and calculated using equations like many technical subfields. The substrate's dielectric properties and trace form must be considered when calculating trace impedance. Most microstrip and stripline impedance estimates use IPC-2141 formulas.

High-speed, high-frequency, and multilayer signalling protocols with GHz bandwidths cannot use these estimates due to their 7% inaccuracy. PCB trace impedance calculators are scarce.

Choose geometric parameters and use the equations to learn how your board's layers affect impedance. Since the dielectric constant is in the impedance equations, choosing the suitable dielectric substrate material for your PCB layout is essential.

Coplanar lines offset strip lines, and waveguides require more sophisticated methods. After choosing the best layer arrangement for your PCB design, utilize a field solver to calculate the area needed to achieve a specific impedance.

Routing layers and power plane capacitance can be balanced on a ten-layer printed circuit board (lines in bold represent plane layers; P = prepreg; L = laminate). The left-hand stack has six signal layers and one narrowly spaced pair of planes.

If the interplane capacitance is needed, this may cause power delivery concerns despite saving routing space. The right-hand stack has six routing layers but quadruples the aircraft pairs of the left. This improves interplane capacitance but decreases routing area.

Altium Designer's Layer Stack Manager simplifies PCB stack-up organization and trace impedance computation. This product's PCB layer stack-up includes an industry-standard field solver. Altium Designer automatically calculates trace impedance for your PCB stack-up.

· The stack-up affects trace impedance, which can be used to fine-tune board impedance.

· Use your design layers to improve trace impedance.

· Impedance calculations must account for dielectric substrate dispersion. Accurate results at any frequency require this.

You can use a variety of standard termination methods to end PCB components.

The layer spacing in your stack up (H in the equation above) is one of the essential aspects in determining signal impedance and other critical design characteristics when developing high-speed circuit boards. Layer layout and separation in your stack-up affect three crucial features of high-speed printed circuit board design:

High-speed device power stability depends on interplanar capacitance. Interplane capacitance can be increased by arranging power and ground planes on adjacent levels with a small gap.

Loop inductance determines whether traces are prone to inductive crosstalk. Layer separation decreases loop inductance.

The layer gap affects capacitive and inductive interaction between traces. This computation will find the even, odd, and differential impedances.

As indicated, the dielectric constant of your substrate affects trace impedance, as shown by the equation above. Impedance calculations and PCB stack-up design must consider substrate dielectric characteristics. Frequency-dependent dielectric constant changes affect coupling, crosstalk, and trace impedance.

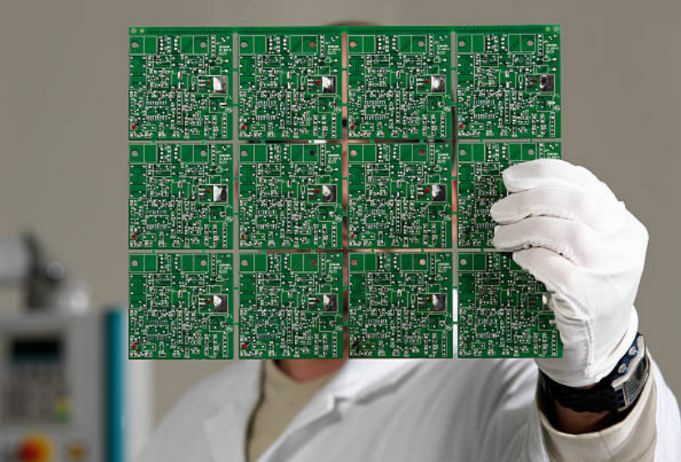

PCBs now support more complex and quicker logic circuitry. Modern PCBs must meet impedance management, crosstalk, and interplane capacitance standards. High-speed PCBs require impedance regulation.

PCB impedance calculators measure trace resistance. To meet PCB impedance requirements, stack-up design is essential. Calculators may be affected by copper roughness or etching.

Altium Designer, a PCB design tool, can estimate PCB impedance for stack-up design. PCB stack-up design. Designers can utilize layer stack management and routing to control board impedance.

Stackup design, PCB impedance calculations, and Altium Designer's involvement in high-speed impedance control are covered in detail in this article.

PCBs were initially used to power slow logic circuits with direct current (DC) and connect logic or discrete components. Today, PCBs have many more uses. Solderable PCBs at low prices were the target. As logic circuits developed, the need for faster interconnects increased, making impedance levels increasingly important. Engineers pressured fabricators to create circuit boards with 50 Ohm impedance.

A PCB's trace impedance depends on its geometry, core and prepreg material, and layers. Different geometries require different approaches due to impedance differences between edge-coupled, embedding, and offset trace topologies.

Some analytical methods and online PCB calculators underestimate copper roughness, dispersion, and etching when predicting PCB impedance. Thus, measuring PCB trace impedance involves distinct methods and instruments.

Ground and power planes are necessary for controlled impedance PCB stackups. Ground planes reduce crosstalk, which causes noise and signal degradation in high-speed circuits.

Signal integrity is maintained through a ground plane's low-impedance return path. Power planes ensure steady power to PCB components. To achieve impedance and signal integrity, the stack-up design must consider the placement and thickness of these planes.

Altium Designer aids PCB stack-up design. This tool aids high-speed design and regulated impedance. Use the field solver in the software to get the stack up with the correct number of layers, power and ground plane locations, and layer thickness for your design.

Altium Designer's layer stack manager is a powerful tool for stack-up creation and maintenance. Layer stack manager provides a stack-up management GUI. This interface lets users create, remove, and determine layer thicknesses. The core, prepreg, and each layer's dielectric constant can be specified.

Altium Designer provides a layer stack manager, routing engine, and many design criteria and constraints to help you construct an appropriate design. For high-speed designs, minimum trace width and clearance between traces help assure proper operation.

In conclusion, high-speed PCB stack-ups must incorporate controlled impedance, crosstalk control, and interplane capacitance. However, online calculators and scientific computations may need help to account for copper roughness and dispersion.

To create a PCB stack-up that meets all your high-speed design needs, utilize a robust PCB design tool like Altium Designer, which contains a field solver, routing engine, and design rules and limits. This lets you make a design-ready PCB stack up. Altium Designer can create a high-speed PCB that works well and looks great.

By continuing to use the site you agree to our privacy policy Terms and Conditions.

Recruit global agents and distributors Join us