In the world of electronics, Printed Circuit Boards (PCBs) are foundational. However, they face a silent threat: corrosion. Corrosion can compromise a PCB's performance, leading to device failures. This article delves into the causes, types, and prevention of PCB corrosion. For businesses relying on electronic devices, understanding and addressing PCB corrosion is crucial. Join us as we explore this topic in depth, providing insights to ensure the longevity and reliability of your electronic components.

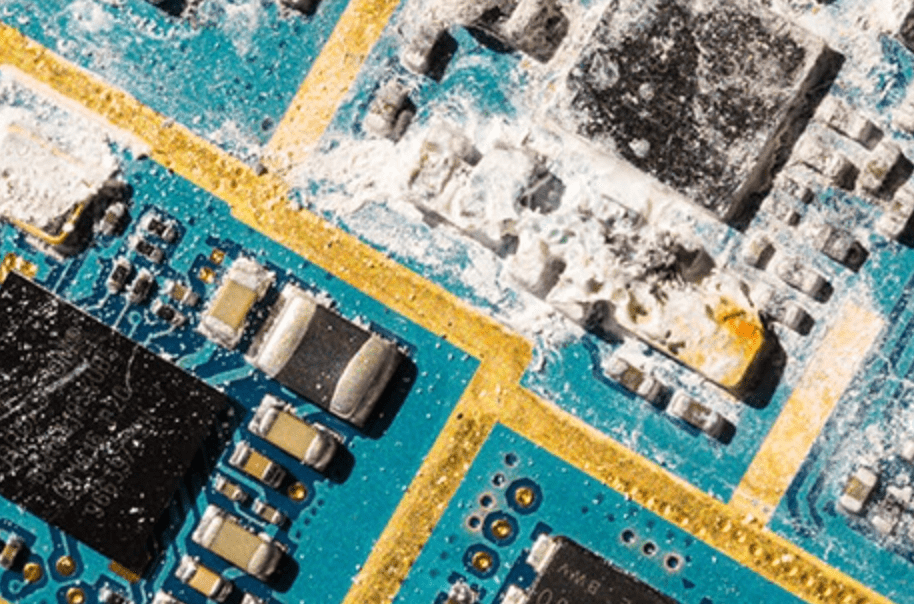

Corrosion refers to the gradual destruction of materials by chemical reactions with their environment. In the context of PCBs, corrosion happens when the board's materials start to degrade because of unwanted reactions with substances in the surrounding environment. This can lead to the formation of unwanted substances on the board, which can disrupt its function.

Printed Circuit Boards are made up of various metals, each serving a unique purpose. These metals, while essential for the board's functionality, have varying degrees of resistance to corrosion.

| Metal | Usage in PCBs | Corrosion Susceptibility |

|---|---|---|

| Copper | Primary metal due to excellent electrical conductivity. | Prone to oxidation, leading to the formation of a greenish layer called copper oxide, which disrupts electrical flow. |

| Gold | Used in high-quality PCBs for superior conductivity. | Resistant to corrosion on its own, but can cause 'galvanic corrosion' when paired with other metals. |

| Silver | Sometimes used for PCB traces because of its superior conductivity. | Can tarnish when exposed to sulfur-containing environments. |

| Tin | Often used as a protective layer for copper. | Provides protection, but can form 'tin whiskers' that might cause short circuits. |

| Nickel | Acts as a barrier layer between copper and other metals. | Can corrode under certain conditions, forming a greenish layer similar to copper. |

Corrosion on printed circuit boards (PCBs) is a concern for many industries, as it can severely impact the performance and lifespan of electronic devices.

One primary cause of this corrosion is moisture. When PCBs are exposed to humid environments or direct water contact, it can initiate the corrosion process.

Another significant factor is the presence of contaminants. Chemicals, salts, and other pollutants in the air can settle on the PCB surface, leading to corrosive reactions.

Additionally, the quality of materials used in the PCB can influence its vulnerability. Inferior metals or protective coatings might not offer adequate resistance against environmental factors.

Lastly, temperature fluctuations can also play a role, as they might cause condensation or stress on the board. Understanding these causes is the first step in preventing potential damage.

Corrosion in PCBs can manifest in various forms, each with its unique characteristics and implications. Recognizing these types is crucial for businesses to implement effective prevention strategies and ensure the longevity of their electronic products.

This occurs when two different metals come into contact in the presence of an electrolyte, leading one metal to corrode faster than the other. For instance, when gold and copper are in close proximity on a PCB, galvanic corrosion can arise, compromising the board's functionality.

This type of corrosion happens when a voltage difference exists between two points on a PCB, and there's moisture present. The voltage drives metal ions from one point to another, forming conductive paths or "dendrites". These dendrites can cause short circuits, leading to device failures.

This localized form of corrosion creates small pits or holes on the metal surface. It's particularly dangerous because it can go unnoticed until significant damage has occurred. Pitting can reduce the thickness of traces on a PCB, affecting its performance.

Occurring in narrow spaces where oxygen is limited, this corrosion type can be found in areas like the overlap of two surfaces. It can lead to the weakening of the PCB structure and potential device malfunctions.

Factors like humidity, temperature, and air pollutants can lead to this type of corrosion. For instance, PCBs exposed to salty air in coastal regions can experience accelerated corrosion rates. There is a study that presents findings on the corrosion behavior of PCB-HASL in marine environments, especially those with industrial pollution.

This arises from repeated wear and small vibrations. The continuous motion causes the removal of protective oxide layers, making the underlying metal susceptible to corrosion.

Corrosion on Printed Circuit Boards is not just a surface-level concern. It can have profound implications on the performance and longevity of electronic devices. Here's how corrosion can impact PCB functionality:

Reduced Conductivity: Corrosion can degrade the conductive paths on the PCB. This hampers the smooth flow of electrical currents, leading to reduced device efficiency.

Component Failure: As corrosion spreads, it can damage vital components on the board. This can result in partial or complete device malfunctions, causing unexpected downtimes.

Short Circuits: Corrosive elements can create unintended connections between circuits. This can lead to short circuits, posing potential safety risks and damaging the device.

Decreased Lifespan: Corrosion accelerates wear and tear. Devices with corroded PCBs tend to have a shorter operational lifespan, leading to increased maintenance and replacement costs.

Compromised Signal Integrity: Corrosion can interfere with the signals transmitted across the board, leading to data loss or miscommunication between components.

Corrosion on a PCB can hinder its performance and reduce its lifespan. Addressing this issue promptly is crucial to maintain the board's functionality. Here, we'll explore various methods and materials to clean corroded PCBs.

IPA is a widely-used cleaning solvent for PCBs. It's adept at dissolving minor corrosion and leaves no residue behind.

Advantages: Safe for most PCB components and effective for light corrosion. Drawbacks: May not be potent enough for severe corrosion.

Drawbacks: May not be potent enough for severe corrosion.

White vinegar, a mild acid, can counteract alkaline corrosion. Its easy availability makes it a popular choice for many.

Advantages: Accessible and cost-effective.

Drawbacks: Might not be strong enough for heavy corrosion. It's essential to rinse thoroughly to prevent residues.

Baking soda, being alkaline, is effective against acid corrosion. Its household availability makes it a convenient option.

Advantages: Effective for acid-induced corrosion and readily available.

Drawbacks: Can be slightly abrasive, so gentle application is recommended. Residues can be left behind if not rinsed properly.

These are specially formulated cleaning solutions designed for PCBs.

Advantages: Specifically designed for PCBs, they can tackle various types of corrosion.

Drawbacks: They tend to be more expensive than household solutions. Some might contain chemicals that require careful handling.

This technique employs ultrasonic waves in a cleaning solution to dislodge corrosion.

Advantages: Highly effective, especially for complex PCBs with areas that are hard to reach.

Drawbacks: Requires specialized equipment and might not be suitable for all PCBs, as some components can be sensitive to ultrasonic waves.

Ensuring the longevity and optimal performance of a PCB requires regular maintenance and timely corrosion cleaning. While there are multiple cleaning methods available, it's vital to choose one that matches the type and severity of the corrosion. Always ensure the PCB is thoroughly dried after cleaning to prevent further issues. Proper care can significantly extend a PCB's operational life and maintain its efficiency.

Corrosion on PCBs can compromise their performance, sometimes to the point of rendering them inoperative. It's crucial for businesses and individuals alike to understand how to prevent this deterioration, ensuring the longevity and reliability of their electronic devices.

One of the primary factors leading to PCB corrosion is the environment. Keeping the PCB in a dry and low-humidity environment is paramount. Excessive moisture can act as a catalyst, speeding up the corrosion process. If you're storing PCBs for an extended period, consider using sealed containers with desiccants, or even employing dehumidifiers in storage areas.

Another effective preventive measure is the application of protective coatings. Conformal coatings, for instance, can provide a shield against external elements that might cause corrosion. When applying these coatings, it's essential to ensure they cover the entire board and all its components for maximum protection.

The quality of materials used in the PCB's manufacture also plays a significant role in its susceptibility to corrosion. Opting for corrosion-resistant metals and high-grade insulating materials during the design and manufacturing process can make a notable difference in the board's resilience.

Regular maintenance and inspections shouldn't be overlooked. By periodically checking and cleaning the PCB, early signs of corrosion can be detected, allowing for timely interventions. When cleaning, it's advisable to use soft brushes and appropriate cleaning solutions to avoid causing any damage.

Lastly, it's essential to be aware of potential contaminants. Certain chemicals can accelerate the corrosion process. Ensuring that the PCB isn't exposed to these harmful substances, even during handling, can be beneficial. Using gloves when handling PCBs and storing them in clean environments can help in this regard.

Corrosion on PCBs can hinder performance and reduce the lifespan of electronic devices. Being aware of its causes and prevention methods is crucial for maintaining the quality and efficiency of your electronics. As a trusted professional PCB supplier, we prioritize delivering corrosion-resistant boards tailored to your needs.

For durable and high-quality PCBs that stand the test of time, choose us as your trusted partner. Elevate your projects with our expert solutions. Contact us today and experience the best in PCB services.

By continuing to use the site you agree to our privacy policy Terms and Conditions.

Recruit global agents and distributors Join us