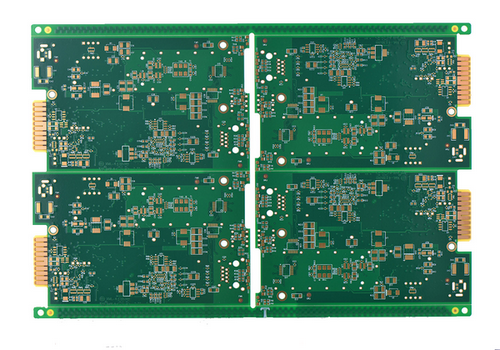

To ensure these PCBs function optimally, their surface finish is of utmost importance. One standout surface finish is ENIG, or Electroless Nickel Immersion Gold. This finish not only enhances the PCB's performance but also ensures its longevity. As we delve deeper into the world of ENIG PCBs, we'll uncover its significance, benefits, and why it's a top choice for many industries.

Every Printed Circuit Board has a surface finish, which serves as a protective layer and ensures proper electrical connectivity. Think of it as a shield, guarding the PCB against external factors while ensuring it works efficiently. Different finishes offer varied benefits, from enhancing solderability to resisting corrosion. As technology advances, the choice of the right surface finish becomes crucial, impacting the PCB's performance and lifespan. In this section, we'll explore the importance of these finishes and introduce you to some common types, setting the stage for our deeper dive into ENIG.

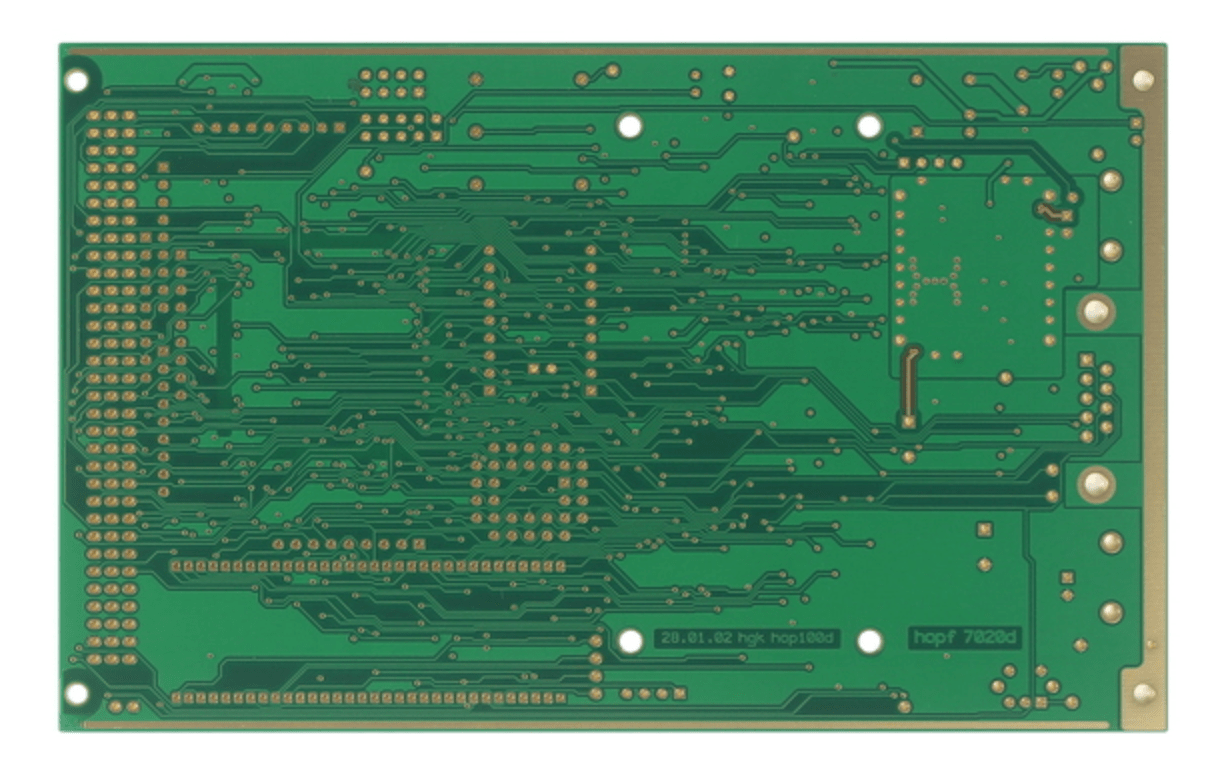

ENIG stands for Electroless Nickel Immersion Gold. It's a type of surface finish used on Printed Circuit Boards. The process involves two main steps. First, a layer of nickel is applied to the PCB. Nickel is tough and acts as a barrier, protecting the underlying copper from wear and tear. Then, a thin layer of gold is added on top. Gold is excellent at conducting electricity and doesn't tarnish or corrode easily. This combination ensures that the PCB remains durable and efficient over time.

ENIG has become a popular choice. It offers a smooth, flat surface, which is perfect for modern devices that require intricate designs. Why ENIG is favored by many and how it stands out in the realm of PCB surface finishes.

When it comes to selecting the right surface finish for Printed Circuit Boards (PCBs), ENIG offers a range of benefits that make it a top choice for many businesses. Let's explore some of the key advantages of ENIG PCBs:

Superior Conductivity: Gold, being a top-notch conductor of electricity, ensures that signals pass through the PCB without any hitches. This means devices work smoothly and efficiently.

Long-lasting: The combination of nickel and gold is like a protective shield. Nickel acts tough, guarding the PCB's base material, while gold prevents tarnishing. Together, they ensure the PCB remains in top condition for a long time.

Flat Surface: ENIG provides a level surface, which is essential for components like Ball Grid Arrays (BGAs) that need a smooth area to attach. A flat surface also means fewer defects during the assembly process.

Resistant to Corrosion: Gold doesn't corrode easily. This resistance to corrosion means that the PCB is less likely to face issues due to environmental factors, ensuring a longer life for electronic devices. Learn more about PCB Corrosion

Suitable for Fine Pitch Components: As electronics become more advanced, components get smaller and more intricate. ENIG's smooth surface is perfect for these tiny components, ensuring they fit and function correctly.

Lead-Free: In today's world, being environmentally friendly is crucial. ENIG is a lead-free finish, aligning with global standards and regulations that aim to reduce harmful substances in electronics.

ENIG PCBs bring together the best of both worlds: the strength of nickel and the conductivity of gold. This duo offers a blend of durability and performance, making ENIG a preferred choice for many in the electronics industry.

| ENIG Properties | |

| RoHS Compliance | Yes |

| Flat Surface | Yes |

| Aluminium Wire Bond | Yes |

| Solderability | Good |

| Shelf Life | One year or higher |

| Cost | High |

Two of the most commonly used finishes are ENIG (Electroless Nickel Immersion Gold) and HASL (Hot Air Solder Leveling). Both have their unique strengths and challenges. Let's delve deeper into these two finishes, comparing their features, benefits, and potential drawbacks.

| Aspect | ENIG (Electroless Nickel Immersion Gold) | HASL (Hot Air Solder Leveling) |

|---|---|---|

| Description | A double-layered finish with nickel plated onto the copper, followed by a gold layer. | PCB is dipped in molten solder, and excess is removed using hot air. |

| Advantages | - Flat Surface - Corrosion Resistance - Lead-Free - Consistent Quality | - Cost-Effective - Tried and Tested - Re-workable |

| Drawbacks | - Higher Cost - Black Pad Syndrome | - Uneven Surface - Lead Concerns - Thermal Stress |

| Best Used For | PCBs requiring fine-pitch components and eco-friendly production. | Cost-sensitive projects, prototypes, and where utmost flatness isn't a priority. |

| Environmental Concerns | Lead-free, making it environmentally friendly. | Traditional HASL uses lead, posing environmental issues. Lead-free options available but with challenges. |

Choosing between ENIG and HASL largely depends on the specific requirements of a project. If precision, flatness, and environmental considerations are paramount, ENIG might be the preferred choice. On the other hand, for cost-sensitive projects where the utmost flatness isn't a priority, HASL can be a viable option.

The Electroless Nickel Immersion Gold (ENIG) surface finish is not just a random choice in the world of electronics and other industries. Its unique properties make it a preferred choice for several applications across different sectors. Here's a closer look at how various industries leverage the benefits of ENIG PCBs.

The electronics sector stands as a major beneficiary of the ENIG finish. Components like printed circuit boards (PCBs), integrated circuits (ICs), and connectors heavily rely on immersion gold. The primary reasons include its superior corrosion resistance, even surface, and consistent thickness. These attributes are vital for components demanding high reliability, especially when they are to function in challenging conditions.

Medical devices, including pacemakers, defibrillators, and heart monitors, demand utmost reliability and longevity. The ENIG finish, with its excellent corrosion resistance and flat surface, ensures these devices perform optimally.

In the aerospace sector, the stakes are high. Devices and components need to be durable, reliable, and safe. Given the extreme conditions these components are exposed to, the corrosion resistance and uniform thickness provided by the ENIG finish become indispensable. It ensures aerospace products remain functional and safe, even in the most demanding situations.

The world of telecommunications is all about speed, reliability, and performance. Devices like routers, switches, and servers are at the heart of this industry. The uniform layer thickness offered by the ENIG finish is crucial for fine-pitch surface mount technology. Additionally, its excellent wire bonding properties are vital for ensuring high-speed data transmission.

Systems like engine control units (ECUs), airbag sensors, and anti-lock brake systems (ABS) are integral to modern vehicles. Given the varying conditions these electronics are exposed to, the ENIG finish, with its corrosion resistance, flat surfaces, and consistent thickness, becomes crucial.

When choosing Electroless Nickel Immersion Gold (ENIG) plating for your printed circuit boards, it's essential to consider several factors to ensure optimal results. Making an informed decision can significantly impact the performance and longevity of your PCBs.

Thickness of the Gold Layer: The gold layer's thickness is crucial. While a thin layer might be cost-effective, it may not offer the desired protection against corrosion. On the other hand, an excessively thick layer could be unnecessary and expensive.

Quality of Nickel: The nickel layer acts as a barrier between the copper and gold. Ensuring high-quality nickel is vital as any impurities can affect the PCB's performance.

Storage Conditions: After the ENIG plating process, the storage conditions of the PCBs matter. It's best to store them in a dry environment to prevent any potential corrosion or degradation.

Cost Implications: While ENIG offers numerous benefits, it's also essential to consider its cost. Balancing between quality and budget can help in making a sound decision.

Supplier Expertise: Lastly, the expertise of the supplier or manufacturer plays a significant role. Working with experienced professionals ensures the plating process meets industry standards and delivers the desired results.

In the realm of electronics, the choice of surface finish plays a pivotal role in determining the performance and longevity of printed circuit boards (PCBs). Electroless Nickel Immersion Gold (ENIG) stands out as a premier choice, offering a blend of durability and high performance. As technology continues to evolve, ensuring the reliability of your PCBs becomes even more crucial.

For those seeking excellence in PCB production, VictoryPCB is your trusted partner. With 20 years of expertise in the industry, we have honed our craft, ensuring top-tier ENIG PCBs for our clients. Don't compromise on quality. Choose VictoryPCB for unparalleled precision and reliability in PCB solutions. Contact us via sales@victorypcb.com and elevate your electronic projects to new heights.

By continuing to use the site you agree to our privacy policy Terms and Conditions.

Recruit global agents and distributors Join us