Over the years, Polyimide PCBs have carved a niche for themselves in the industry, thanks to their unique properties and advantages. As technology advances and demands evolve, the choice of PCB material becomes crucial. Polyimide, with its distinct benefits, has emerged as a top contender, meeting the challenges of modern electronics. In this article, we'll delve deeper into the rise of Polyimide PCBs and explore why they are becoming an industry favorite.

Polyimide is a type of polymer known for its exceptional heat resistance, electrical insulation properties, and stability across a wide range of temperatures. It is commonly used in the manufacturing of Printed Circuit Boards where high performance and reliability are required.

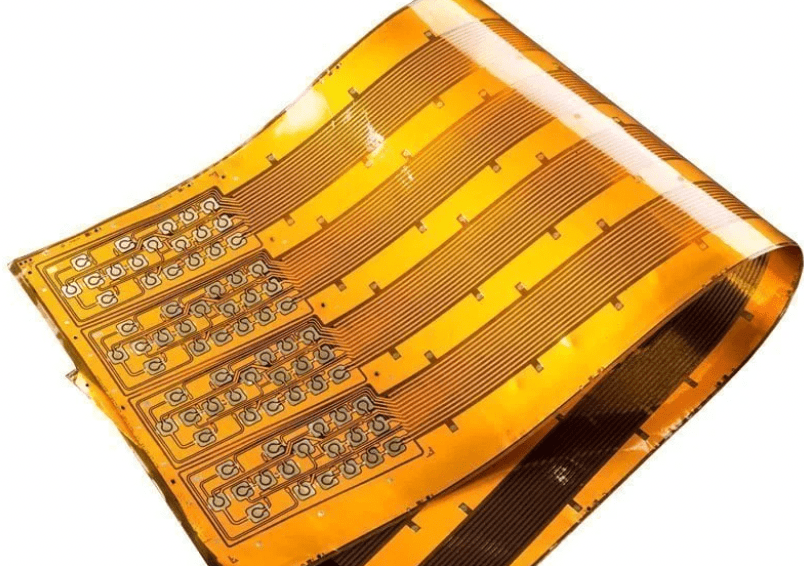

Polyimide PCBs are especially popular in applications that involve extreme temperatures or harsh environments, as they maintain their integrity and functionality under conditions that would cause other materials to fail. The material’s flexibility also makes it a preferred choice for flexible PCBs, which are used in a variety of electronic devices.

In addition to its thermal and electrical properties, polyimide is also resistant to chemicals and radiation, further expanding its range of applications in the electronics industry.

When it comes to choosing a material for Printed Circuit Boards, Polyimide and FR4 are two of the most common options. Each material has its unique set of properties, making them suitable for different applications. Understanding the differences between Polyimide and FR4 is crucial for making an informed decision based on the specific needs of your project.

| Property | Polyimide | FR4 |

|---|---|---|

| Thermal Resistance | High (up to 250°C) | Lower (degrades above 130°C) |

| Cost | Higher | Lower |

| Flexibility | Highly flexible | Less flexible |

| Chemical Resistance | Excellent | Good |

| Mechanical Strength | High | Moderate |

| Electrical Insulation | Good | Good |

| Moisture Absorption | Low | Moderate |

| Applications | High-temperature environments, flexible circuits, aerospace, medical devices | Consumer electronics, automotive, industrial applications |

FR4 is a glass-reinforced epoxy laminate material, known for its good electrical insulating properties and reasonable price point. It is widely used in the electronics industry for a variety of applications. However, FR4 has a lower thermal resistance compared to Polyimide, making it less suitable for high-temperature environments. The material can start to degrade at temperatures above 130°C, which can be a significant limitation for certain applications.

Polyimide, on the other hand, excels in high-temperature environments. It can withstand temperatures up to 250°C without degrading, making it an ideal choice for applications that involve extreme heat. Additionally, Polyimide is known for its excellent chemical resistance and mechanical strength, further enhancing its suitability for challenging conditions.

While Polyimide offers superior performance in high-temperature environments, it also comes at a higher cost compared to FR4. This cost difference can be a critical factor, especially for large-scale production. Therefore, it is essential to weigh the benefits of Polyimide against its cost to determine if it is the most cost-effective option for your specific application.

Polyimide PCBs come in various types, each designed to meet specific requirements and applications in the electronics industry. Understanding these types is crucial for selecting the most suitable Polyimide PCB for your needs.

Fexible Polyimide PCB: These PCBs are known for their flexibility, allowing them to bend and fold without damaging the circuit. They are ideal for applications where space is limited, and the PCB needs to conform to the shape of the device, such as in cameras, mobile phones, and wearable electronics.

Rigid Polyimide PCB: Unlike their flexible counterparts, rigid Polyimide PCBs are stiff and do not bend. They offer higher mechanical strength and are commonly used in applications that require robustness and durability, such as in aerospace and industrial equipment.

High-Temperature Polyimide PCB: These PCBs are designed to withstand extremely high temperatures, often up to 250°C. They are suitable for use in harsh environments, such as in automotive engines, industrial machinery, and aerospace applications, where exposure to high temperatures is common.

Multilayer Polyimide PCB: These PCBs consist of multiple layers of circuits, providing more space for components and connections. They are used in complex electronic devices that require high functionality in a compact space, such as in computers, servers, and advanced communication devices.

Polyimide PCBs are renowned in the electronics industry for their exceptional properties and performance, offering a range of advantages that make them a preferred choice for various applications.

High-Temperature Resistance: One of the standout features of Polyimide PCBs is their ability to withstand extreme temperatures. They remain stable and functional even in environments reaching up to 250°C, making them ideal for use in high-temperature applications such as aerospace, automotive, and industrial machinery.

Flexibility: Polyimide PCBs are highly flexible, allowing them to bend and fold without causing damage to the circuits. This flexibility is crucial for devices where space is limited, and the PCB needs to conform to the shape of the product, such as in wearable electronics, flexible displays, and compact medical devices.

Chemical Resistance: These PCBs exhibit excellent resistance to chemicals, ensuring they maintain their integrity even when exposed to harsh chemical environments. This property is particularly beneficial in industrial applications where the PCB may come into contact with aggressive chemicals.

High Mechanical Strength: Despite their flexibility, Polyimide PCBs also offer high mechanical strength, ensuring they can withstand physical stress and strain. This durability is essential in applications that require robust and reliable performance, such as in aerospace components and industrial equipment.

Long-Term Reliability: Polyimide PCBs are known for their long-term reliability, maintaining their performance over extended periods. This reliability is crucial for applications where the PCB must function flawlessly for the life of the product, such as in medical implants and safety-critical automotive components.

Excellent Electrical Properties: Polyimide PCBs provide outstanding electrical insulation, even at high temperatures, ensuring the integrity of the electrical signals. They also have a low dielectric constant, which is beneficial for high-speed signal transmission, making them suitable for use in advanced communication devices and high-frequency applications.

Polyimide PCBs, with their unique properties, find applications across a diverse range of industries. Their ability to perform under extreme conditions makes them an ideal choice for various specialized uses.

In the aerospace and aviation industries, reliability and performance under extreme conditions are paramount. Polyimide PCBs are used in these sectors due to their high-temperature resistance and durability. They are found in aircraft engine control systems, instrumentation, and other critical components.

The automotive industry requires components that can withstand high temperatures and vibrations. Polyimide PCBs are used in engine control units, transmission sensors, and other automotive electronics due to their robustness and reliability.

In the medical field, reliability is crucial, especially for devices that are implanted in the human body or used in critical care situations. Polyimide PCBs are used in pacemakers, defibrillators, and other medical devices because of their reliability and biocompatibility.

The trend towards miniaturization in consumer electronics has increased the demand for flexible PCBs. Polyimide PCBs are used in smartphones, tablets, and wearable devices due to their flexibility and thin profile.

In the telecommunications industry, high-speed signal transmission is essential. Polyimide PCBs, with their excellent electrical properties, are used in routers, switches, and other communication equipment.

When selecting Polyimide PCBs for your electronic projects, several crucial factors need to be taken into consideration to ensure optimal performance and reliability.

Cost: While Polyimide PCBs offer numerous advantages, they can be more expensive than other types of PCB materials. It’s important to balance the cost with the benefits to determine if Polyimide is the most cost-effective option for your project.

Manufacturer Experience: The experience and expertise of the PCB manufacturer play a crucial role. Choose a manufacturer with a proven track record in producing high-quality Polyimide PCBs.

Flexibility: If your project requires a flexible PCB, Polyimide is an excellent choice. However, the degree of flexibility needed should be considered, as it can impact the thickness and design of the PCB.

By carefully considering these factors, you can make an informed decision and select a Polyimide PCB that meets the specific needs of your application, ensuring reliability and performance.

In conclusion, Polyimide PCBs stand out as a robust and versatile option for a wide range of electronic applications. Their exceptional ability to withstand high temperatures, coupled with their flexibility and chemical resistance, makes them an ideal choice for challenging environments and demanding applications. Whether it’s for aerospace, medical devices, or consumer electronics, Polyimide PCBs deliver reliability and performance that is hard to match.

If you’re looking to take your electronic projects to the next level with Polyimide PCBs, we encourage you to reach out to us. Our team of experts is ready to guide you through the selection process, ensuring you choose the perfect Polyimide PCB for your needs. We pride ourselves on delivering high-quality PCBs and unparalleled customer service. Don’t settle for less; choose the best with our Polyimide PCBs. Contact us today to get started and elevate your electronic projects to new heights.

By continuing to use the site you agree to our privacy policy Terms and Conditions.

Recruit global agents and distributors Join us