Today, the significance of PCB cannot be over emphasize. It is found in any electronic device ranging from calculators to laptops. And it is the most important component in any electronic.

Due to the growing demand for electronics in different fields and industries, PCB technology have rapidly advanced to meet our needs and requirements. Designing a PCB can be a complex and challenging process.

Even the smallest errors can cause a huge malfunction in the entire system. This is why you need a professional and competent manufacturer of PCB to handle your PCB fabrication.

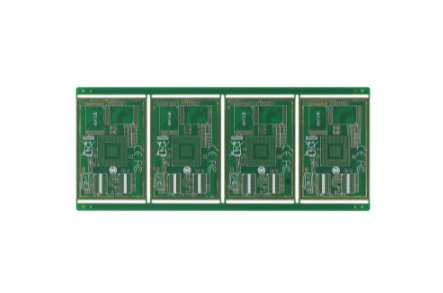

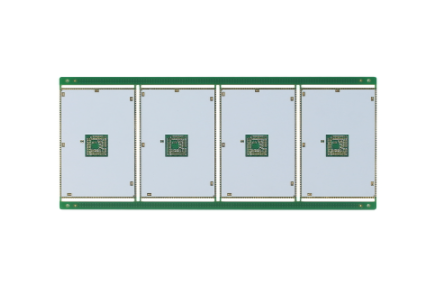

Printed circuit board (PCB) is a board or a card that is usually made of non-conducting materials like glass and fiber, on which a conducting material is etched into.

They contain traces and lines that electrically connects various components together. The connections are firmly held in place and supported by solder which serves as a mechanical adhesive.

This article discusses on the types of PCB and the benefits of fabrication.

The three major types of PCB are;

They have just a layer of both non-conductive material and conductive material. The conductive material only occupies a surface. They can only be used for simple circuits

The two sides of the non-conductive material is covered by a layer of conductive material. They also have drilled holes that enable interconnection of the plates. These circuit boards have wider applications than the single sided boards.

These type have multiple layers of conductive materials that are separated and insulated by multiple layers of non-conductive materials. Pads are what connects the multiple layers together.

· You can effectively and efficiently organize your design:

The ability to have access to your design and identify any area the needs improvement is one of the major advantage of PCB fabrication. This way, the time and cost of fabrication is greatly reduced.

· Design errors and mistakes are reduced:

With the aid of design experts errors that may show up from time to time are easily and quickly corrected before printing and fabrication.

· Customize the appearance of your product:

The appearance of your PCB is important as it can attract the attentions of potential investors and clients. And PCB fabrication allows you to customize the appearance of your product.

· Unrestricted access to your product:

You will be able to have access to your product at any stage of the process and communicate your specifications and requirements. There by, redesign and rework is avoided.

· Reduced amount of time and energy used:

Making use of the right program software allows you to be able to organize your design process. The production of PCB can be carried out immediately the design layout is done.

Hence, errors that would have taken time and energy to correct is avoided.

We have a brilliant team that is ready work with you to ensure that your PCB fabrication meet your desired requirements and specifications. Click here to view our products.

By continuing to use the site you agree to our privacy policy Terms and Conditions.

Recruit global agents and distributors Join us