Given the significance of printed circuit boards in electrical products, you should think carefully about the material to use when making PCBs.

PCB Rogers can provide you with the best high-quality PCB assembly and fabrication at the lowest prices imaginable.

FR-4, HDI, Rogers PCB material, and other types of PCB materials are only a few examples of the several diverse PCB materials available.

To help customers save product prices, we typically use the industry-standard FR-4 material for the printed circuit boards, which is a good choice because FR-4 material is inexpensive and efficient for many applications.

Although there are other types of PCB materials besides FR-4, Rogers and FR-4 are the most significant.

Nevertheless, many customers are unclear about these materials. To introduce FR-4 and Rogers materials, PCB rogers was introduced into the market.

As a composite material for glass-reinforced epoxy laminate material, FR-4 refers to a grade of material rather than a specific substance.

Woven fiberglass cloth with a flame-resistant epoxy resin binder makes up FR-4. Furthermore, FR, which stands for flame retardant, indicates that the material complies with UL94V-0 standards.

FR-4 glass epoxy is a well-liked, adaptable high-pressure thermoset plastic laminate grade with good strength-to-weight ratios for electronic engineers and designers.

FR-4 is most frequently employed as an electrical insulator because of its almost negligible water absorption and high mechanical strength.

In both dry and wet environments, the material is recognized to maintain its strong mechanical properties and electrical insulating capabilities.

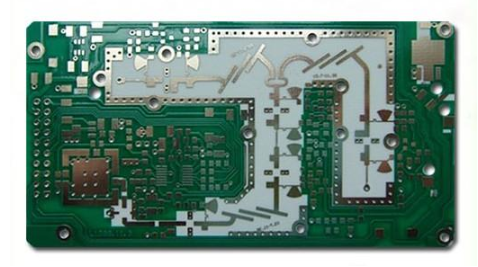

Circuit boards are made using laminate materials, which are produced by Rogers. The majority of circuit boards are built of FR4 (Flame Retardant Level 4), a glass fiber/epoxy composite with laminated copper foil on one or both sides.

Rogers will sell you FR-4 laminates (a copper laminate over an FR-4 core), but they are better known for cores with superior high-frequency characteristics, such as PTFE (Teflon).

While they cost more than fiberglass, they exhibit less loss at high frequencies. They are hence suitable for RF circuit boards.

1. Rogers PCB material is more expensive than FR-4 material.

2. Rogers material is superior to FR-4 material for high frequencies.

3. FR-4 material loses more signal because it has a higher Df (dissipation factor) than Rogers PCB material.

4. Rogers PCB material has a wider range of dielectric constant Dk values than FR-4 material in terms of impedance stability.

5. FR-4 has a lower dielectric constant (Dk) than Rogers material, which ranges from 6.15 to 11, at about 4.5.

6. Rogers PCB material exhibits less variation in temperature control than FR-4 material.

The essential benchmark for PCB substrates is FR-4 material, which successfully strikes a balance between price, robustness, performance, manufacturability, and electrical qualities.

However, because performance and electrical characteristics are crucial to your designs, Rogers PCB materials have the following advantages:

low loss of electrical signal

Affordable PCB manufacturing

decreased dielectric loss

improved thermal control

wide range of values for the dielectric constant (2.55-10.2)

For use in space applications, low outgassing

more effective impedance control

When it comes to premium Rogers PCB and other sorts of rogers PCB materials you can rely on us as a leading brand with a strong commitment to quality.

Therefore, if you require any of our goods or services, kindly click to get in touch with us. We look forward to working with you.

By continuing to use the site you agree to our privacy policy Terms and Conditions.

Recruit global agents and distributors Join us