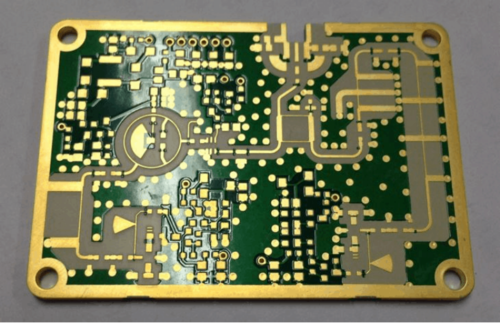

There are different PCBs around us but heavy copper PCB stands out with their unique properties. Heavy Copper PCB is a printed circuit board with higher copper weight than normal PCB. The extra amount of copper in this PCB makes it a better electrical conductor.

A quality heavy copper PCB from a reputable manufacturer is suitable for high-power electronic devices like motor controllers and power supplies. The thickness range of heavy copper PCB is from 3 – 10 oz. per square foot.

Read on as we take you through important things you need to know about this PCB. In the end, you will be able to take an informed decision.

There are some essential components of heavy copper PCB you need to know. Some of them are:

The conductive pathways on a PCB connect different components and circuits. Heavy copper PCBs typically have thicker copper traces to handle higher current and power loads.

The small openings in the PCB connect different layers of the circuit. Heavy copper PCBs often have larger vias to accommodate thicker copper traces.

The base material used to construct the PCB. Common options include FR-4, CEM-1, and CEM-3. Heavy copper PCBs typically use materials with higher thermal conductivity and better mechanical properties.

The protective coating is applied to the PCB to prevent accidental soldering and improve the overall appearance of the circuit. The small electronic components that are directly soldered to the surface of the PCB, such as resistors, capacitors, and ICs.

The metal plates or fins attached to the PCB dissipate heat generated by high-power components. Heavy copper PCBs often have larger heat sinks to handle the increased thermal load.

The larger electronic components are inserted through holes in the PCB and soldered on the other side, such as connectors and power supplies.

There are different benefits of using this PCB. Some of the benefits are:

The increased copper content in heavy copper PCBs provides better heat dissipation, which helps to keep electronic components cool and functioning properly.

Heavy copper PCBs have a higher amount of copper than standard PCBs, which allows them to handle higher power levels without overheating or damage.

Heavy copper PCBs have a longer lifespan compared to standard PCBs as they can handle higher power levels and are more durable, which reduces the need for frequent replacements. It is more robust and resistant to damage, which makes them ideal for use in harsh or demanding environments.

Heavy copper PCBs are a cost-effective solution for high-power applications as they can handle high power levels without the need for additional cooling or heat dissipation systems.

Heavy copper PCBs can be designed to meet specific requirements, such as high current or high voltage applications, which makes them suitable for a wide range of applications.

Investing in quality materials is very essential for quality project delivery. As a reputable manufacturer, we produce the best quality products for our clients. Kindly contact us for your PCB today. Click here to view our products.

By continuing to use the site you agree to our privacy policy Terms and Conditions.

Recruit global agents and distributors Join us