Rogers PCB

Rogers PCB laminate are the raw materials we have chosen to one of the best. We have prepared a sufficient conventional Rogers PCB laminate stock, that can on time delivery to your Rogers PCB.

ROGERS 4003C and ROGERS 4350B provide a more cost-effective and processable choice of high frequency materials than PTFE due to their excellent low dielectric loss characteristics, and are widely used in cellular base station antennas and power amplifiers, microwave point-to-point connectivity (P2P), automotive radar and sensors, radio frequency identification (RFID), high frequency head (LNB) of direct broadcast satellites, and other fields.

Find out about our more info, Please contact us at sales@victorypcb.com.

Monthy Capability: 1200 Sq M/Month

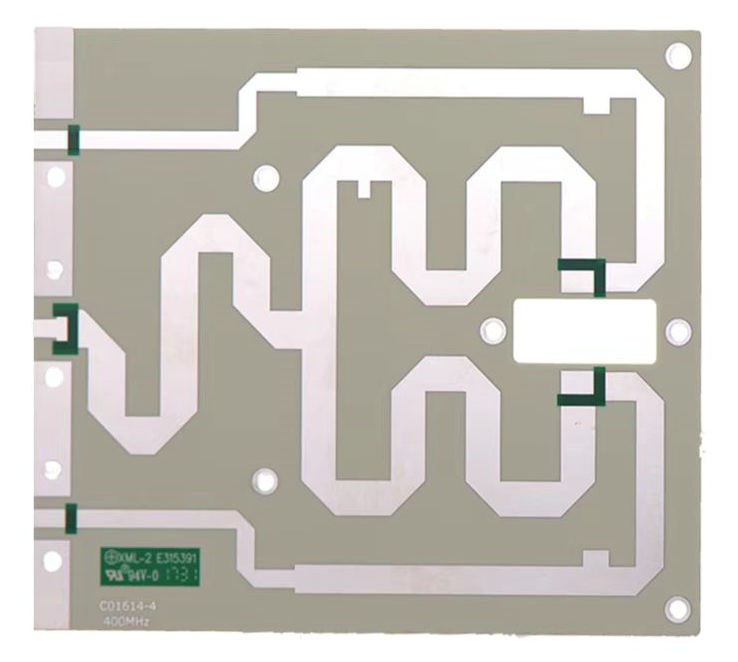

Layer: 2 Layers

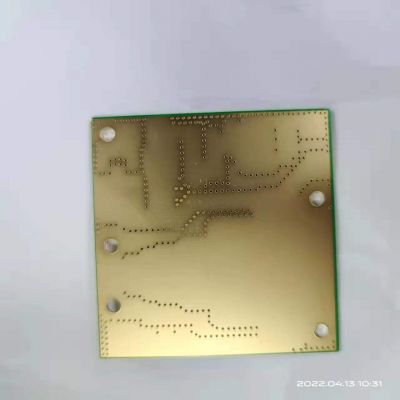

Material: Rogers RO4003C

Dimension: 95*95mm

Finished board thickness: 1.6mm

Finished copper thickness: 1oz

Min Trace Width/Space: 15mil

Min hole size: 0.5mm

Surface finishing: LF HAL

Application field: Communication Devices

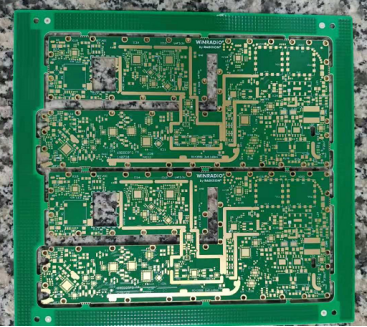

Advantage of Victory PCB

A Professional PCB Manufacturer since 2005

Small and Middle/Large batches, Multiple Varities, Short Lead Time

Certificated with UL (E315391), ISO 14001, IATF16949, ISO 9001, SGS, ISO13485, SA8000.

Capablity 60,000Sqm/3000PNs per month, 500staffs

Make oversized board (reach to 1200mm)

Quotation will be provided within 12hours

15 years experience on PCB exporting

10% sales revenue invested in R&D and advanced automatic equipment from Japan, Taiwan and Germany every year

Product:Single Sided, Double Sided and Multilayer PCB, Rigid PCB,Flex PCB,Rigid-flex PCB,AL-base PCB.

PCB Production Capability

| Material | CEM-3,FR-4(Normal to High Tg),High CTI FR-4,PolyImide(PI) ,Aluminum Base,Rogers |

| Surface finish | HAL, HASL Leadfree, ENIG, Chem Tin, OSP, Gold Finger, Immersion Silver, ENEPIG |

| Min. Core thickness | 4mil/0.1mm |

| Prepreg type | 1080, 2116, 7628, 106, 3313, 2165, 1500. |

| Max board size | 24.41X47.24inch/620X1200mm |

| Copper thickness | Min. base copper 1/3Oz |

| Max. base copper 10Oz |

| Min. board thickness | 2- Layer 0.2mm/8mil |

| 4-Layer 0.35mm/14mil |

| 6-layer 0.65mm/26mil |

| 8-Layer 1.0mm/40mil |

| 10-Layer 1.3mm/51mil |

| 12-Layer 1.6mm/63mil |

| 14-Layer 1.8mm/71mil |

| 16-Layer 2.0mm/79mil |

| AOI (Automatic Optical Inspection) | Max.table size: 685X685mm |

| Max.inspect size: 620X620mm |

| Max. thickness: 3.20mm(126mil) |

| Min. thickness: 0.10mm(4mil)-core |

| Min. width/gap: 3mil/3mil |

| Board thickness Tolerance | ±0.10mm(4/6layers) |

| ±0.13mm(8/10layers) |

| ±0.15mm(12/14/16layers) |

| Max.board thickness | 6.0mm/236mil |

| Min.line width/space | 3/3mil |

| Min hole size | 4mil/0.1mm |

| PTH wall thickness | ≧25µm |

| Max. aspect ratio | 12:01 |

| PTH dia. Tolerance | ±0.075mm/3mil(Standard), ±0.05mm/2mil(Advanced) |

| NPTH dia. Tolerance | ±0.05mm/2mil(On laminate area) |

| ±0.03mm(On ground area) |

| Hole location Tolerance | ±0.075(Standard) ±0.05mm(Advanced) |

| ±0.13(2nd drilled hole to 1st drilled hole location (mm) |

| Slot size tolerance | ±0.075mm(board thickness≤1.0mm) |

| ±0.10mm (board thickness>1.00mm) |

| V-CUT Remain thickness tolerance | ±0.10mm(Standard), ±0.076mm(Advanced) |

| Peelable mask Thickness | ≥8mil(0.2mm) |

| Insulation Resistance | >1012Ω |

| Through hole Resistance | <300Ω |

| Current breakdown | 10A |

| Peel Strength | 1.4N/mm |

| S/M Abrasion | >6H |

| Thermal stress | 288℃ 20Sec |

| Test Voltage | 20-300V |

| Min.blind/burried via | 4mil/0.1mm |

| Impedance control | (50Ω-100Ω)±10%(Standard)、(50Ω-100Ω)±7%(Advanced) |